Oat peptide milk and preparation method thereof

A technology of oat peptides and oats, which is applied in dairy products, milk preparations, plant protein processing, etc., can solve the problems of affecting nutritional efficacy, difficulty in forming, and complicated preparation process, and achieves improved protein functions, easy large-scale production, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

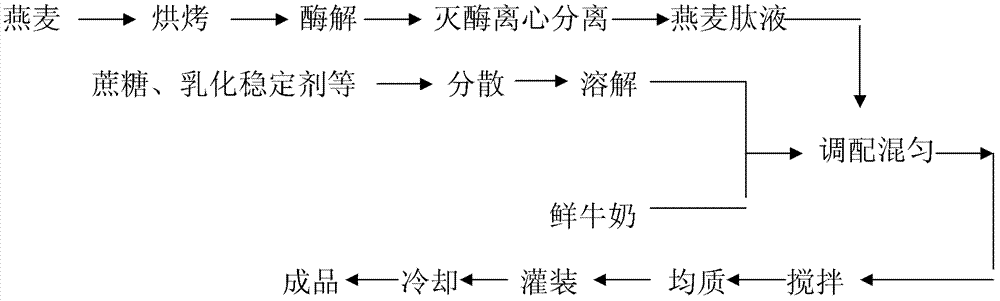

[0047] Prepare Oat Peptide Serum, as in figure 1 shown.

[0048] (1) Pretreatment of oats: bake oats at a temperature of 100° C. for 30 minutes, then add water equivalent to 6 times the mass of oats and pass through a colloid mill to obtain oat slurry.

[0049] (2) Enzymolysis of oat slurry: add Novozymes compound hydrolase (Viscozymel) and Novozymes alkaline protease (Alcalase 2.4L) mixture (mass ratio 1:1) to oat slurry according to 0.4% of oat protein mass , the pH of the slurry system was adjusted to 8.5 with 0.5 mol / L sodium hydroxide solution, and the enzymatic hydrolysis was carried out at 45°C.

[0050] (3) Preparation of oat peptide liquid: when the degree of hydrolysis reaches 6%, heat at 95° C. for 30 min to inactivate the enzyme to terminate the enzymolysis reaction; centrifuge at 4000×g for 30 min to separate the supernatant liquid as oat peptide liquid.

[0051] (4) Preparation of oat peptide whey: after dissolving sucrose, emulsifier and stabilizer with water,...

Embodiment 2

[0054] (1) Pretreatment of oats: bake oats at a temperature of 110° C. for 25 minutes, then add water equivalent to 8 times the mass of oats, and pass through a colloid mill to obtain oat slurry.

[0055] (2) Enzymolysis of oat slurry: add Novozymes compound hydrolase and Novozymes alkaline protease mixture (mass ratio 1:1) to the oat slurry by 0.8% of oat protein quality, and use 0.5mol / L hydrogen Sodium oxide solution adjusted the pH of the slurry system to 8.0, and carried out enzymatic hydrolysis at 55°C.

[0056] (3) Preparation of oat peptide solution: when the degree of hydrolysis reaches 9%, heat at 95° C. for 15 minutes to inactivate the enzyme to terminate the enzymolysis reaction; centrifuge at 8000×g for 30 minutes to separate the supernatant to be oat peptide solution.

[0057] (4) Preparation of oat peptide whey: after dissolving sucrose, emulsifier and stabilizer with water, add oat peptide solution, then add fresh milk, and finally dilute with water, the final ...

Embodiment 3

[0060] (1) Pretreatment of oats: bake oats at a temperature of 125° C. for 10 minutes, then add water equivalent to 10 times the mass of oats and pass through a colloid mill to obtain oat slurry.

[0061] (2) Enzymolysis of oat slurry: add Novozymes compound hydrolase and Novozymes alkaline protease mixture (mass ratio 1:1) to the oat slurry according to 1.2% of oat protein quality, and use 1mol / L of hydrogen to oxidize The sodium solution adjusted the pH of the slurry system to 7.5, and carried out enzymatic hydrolysis at 60°C.

[0062] (3) Preparation of oat peptide solution: when the degree of hydrolysis reaches 12%, heat at 95° C. for 15 minutes to inactivate the enzyme to terminate the enzymolysis reaction; centrifuge at 6000×g for 20 minutes to separate the supernatant to be oat peptide solution.

[0063] (4) Preparation of oat peptide whey: after dissolving sucrose, emulsifier and stabilizer with water, add oat peptide liquid, then add fresh milk, and finally dilute wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com