Method for preparing high-adhesion diamond coating with pulse laser

A diamond-coated, high-adhesion technology, applied in metal material coating process, coating, ion implantation plating, etc., can solve problems such as inability to completely remove the surface of the tool, reduce the hardness and strength of the tool, and cause large damage to the substrate , to achieve the effect of simple and practical process, improving bonding strength and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

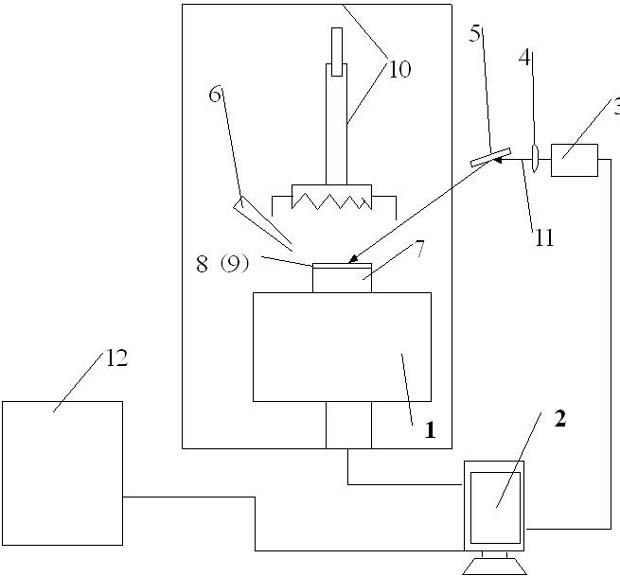

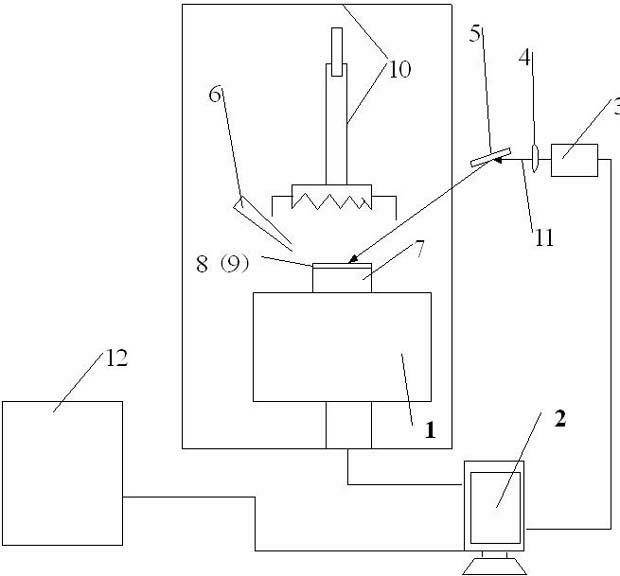

[0032] Laser shock peening improves the adhesion between diamond coating and YG6 cemented carbide tool

[0033] Clean the surface of YG6 cemented carbide tool 7 with industrial alcohol or acetone solution, and then coat the surface with a uniform layer of black paint 8, select Nd:YAG solid-state laser generator 3, the laser energy is 200m ~2J, and the spot diameter is 0.8mm , the frequency is 8HZ, the pulse width is 8ns, and the overlap rate is 50%. The computer control system 2 is used to control the movement track of the Nd:YAG solid-state laser generator 3 and the CNC five-axis worktable 1. The laser beam 11 is adjusted through the optical lens 4 The spatial distribution of laser energy, the laser beam 12 is radiated to the black paint surface 9 through the reflector 5, the device 6 for applying the water-constrained layer is activated, the first impact strengthening is performed on the matrix of the tool 7, and the residual black on the surface of the tool is removed with i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com