PVC (polyvinyl chloride) centrifugal mother liquor wastewater recycling process utilizing tubular membrane filter

A centrifuge mother liquor and filter technology, applied in the direction of water pollutants, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of long time consumption, high construction cost and operation cost, large amount of waste water, etc., and achieve reduction Concentrated water discharge, stable treatment effect, and the effect of reducing source water turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

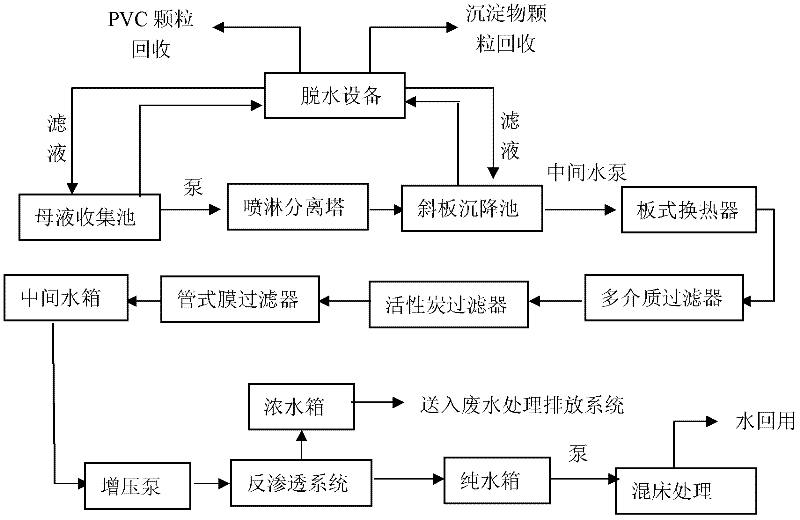

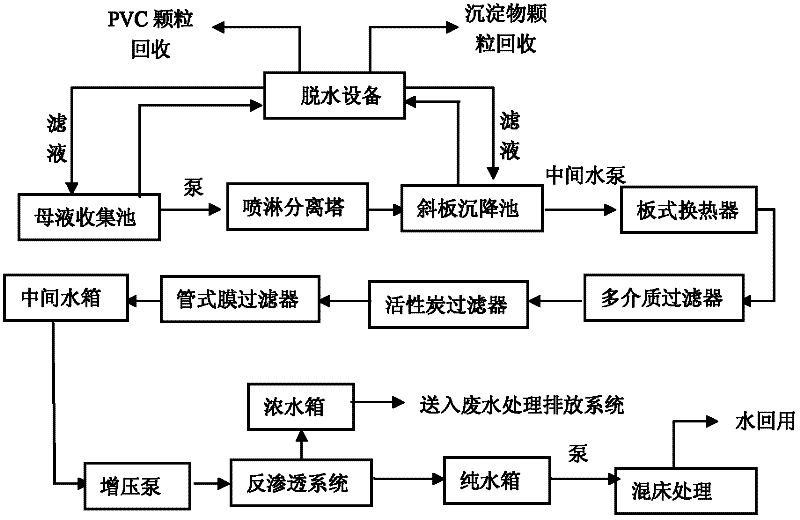

[0044] The mass concentration of suspended solids (SS) in the PVC centrifuge mother liquor wastewater produced in the production process of PVC (polyvinyl chloride) is 30-400 mg / L, mainly PVC particles. At the same time, the temperature is high, generally around 60-70°C. After being collected into the mother liquor collection tank, large PVC particles settle to the bottom of the pond to form sediment. The sediment is treated by a pump dehydrator, PVC is recycled, and the filtrate is returned to the mother liquor for collection. pool; the clear liquid is pumped into the spray separation tower for preliminary degassing and cooling, and then flows into the inclined plate settling tank for sedimentation treatment. Dosing chemicals in the inclined plate settling tank, further recovering finer PVC particles, and removing the dispersant, Substances such as initiators and terminators that will pollute the membrane, after the mother liquid wastewater settles in the inclined plate settli...

Embodiment 2

[0046] Including the conditions and treatment process in Example 1, the difference is that in the reverse osmosis pretreatment, the mother liquid wastewater is sent to the plate heat exchanger through the intermediate water pump to cool down, and then directly enters the tubular membrane filter for treatment, and then enters the Intermediate tank and subsequent reverse osmosis system. Reduced access to multi-media filters and activated carbon filters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com