Low-viscosity vinyl acetate-ethylene (VAE) copolymer emulsion and synthetic method and application thereof

A vinyl acetate, low viscosity technology, applied in the direction of monocarboxylate copolymer adhesive, adhesive type, textile and paper making, etc. The problem of low alkali resistance retention rate, etc., achieves the effect of good shear stability, high alkali resistance retention rate and good positioning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

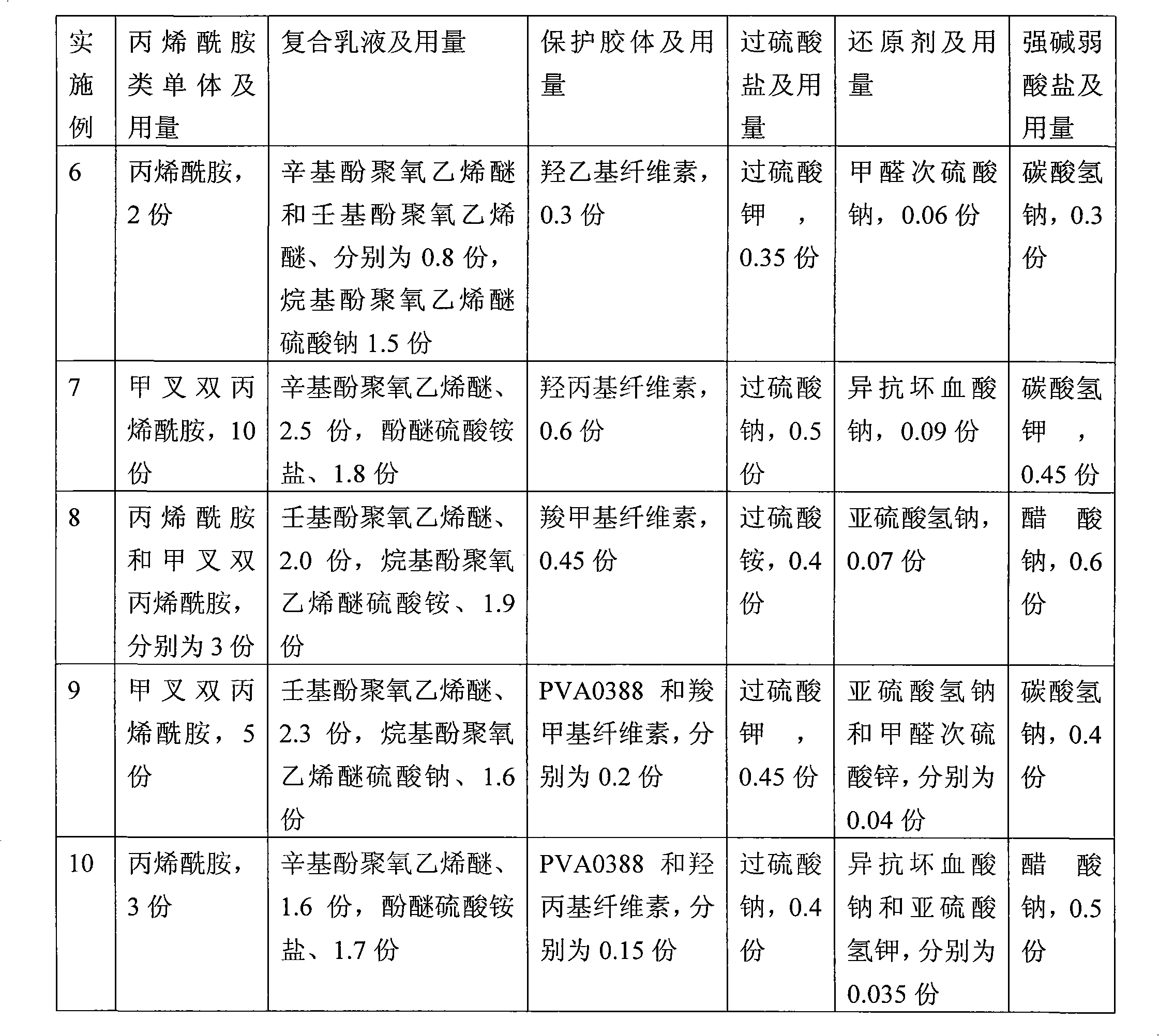

Examples

Embodiment 1

[0054] A kind of synthetic method of low-viscosity vinyl acetate-ethylene copolymer emulsion:

[0055] (1) Preparation of raw materials

[0056] 1) Prepare the emulsifier system: add 45 parts of deionized water, 0.3 parts of hydroxyethyl cellulose, 1.5 parts of nonylphenol polyoxyethylene ether and 1.5 parts of alkylphenol polyoxyethylene ether sodium sulfate into the emulsifier tank, and start stirring Warm up to 60°C and stir for 30 minutes, fully mix and dissolve;

[0057] 2) Prepare initiator solution: add 1.5 parts of deionized water, 0.04 parts of formaldehyde sodium sulfoxylate to initiator tank a, stir and dissolve; add 18 parts of deionized water, 0.35 parts of sodium persulfate, and 0.1 part of bicarbonate to initiator tank b Sodium, stir to dissolve;

[0058] 3) Preparation of methylene acrylamide monomer solution: add 10 parts of deionized water and 2 parts of methylene acrylamide monomer, start the stirrer, and mix well.

[0059] 4) Add 0.02 parts of sodium forma...

Embodiment 2

[0074] A kind of synthetic method of low-viscosity vinyl acetate-ethylene copolymer emulsion:

[0075] (1) Preparation of raw materials

[0076] 1) Prepare the emulsifier system: add 50 parts of deionized water, 0.4 parts of hydroxypropyl cellulose, 2.5 parts of octylphenol polyoxyethylene ether and 1.5 parts of phenol ether ammonium sulfate into the emulsifier tank, start the agitator, and heat up to Stir at 50°C for 30 minutes, fully mix and dissolve;

[0077] 2) Preparation of initiator solution: Add 1.7 parts of deionized water and 0.04 parts of sodium formaldehyde sulfoxylate to initiator tank a, stir and dissolve; add 19 parts of deionized water, 0.4 parts of potassium persulfate, and 0.2 parts of sodium acetate to initiator tank b, Stir to dissolve;

[0078] 3) Prepare acrylamide monomer solution: add 12 parts of deionized water and 10 parts of acrylamide monomer, start the stirrer, and mix well.

[0079] 4) Add 0.03 parts of sodium formaldehyde sulfoxylate and 2 par...

Embodiment 3

[0094] A kind of synthetic method of low-viscosity vinyl acetate-ethylene copolymer emulsion:

[0095] (1) Preparation of raw materials

[0096] 1) Prepare the emulsifier system: add 50 parts of deionized water, 0.6 parts of carboxymethyl cellulose, 2.5 parts of nonylphenol polyoxyethylene ether and 2.0 parts of alkylphenol polyoxyethylene ether ammonium sulfate into the emulsifier tank, and start stirring Warm up to 70°C and stir for 30 minutes, fully mix and dissolve;

[0097] 2) Prepare initiator solution: add 2.0 parts of deionized water, 0.05 parts of formaldehyde sodium sulfoxylate to initiator tank a, stir and dissolve; add 20 parts of deionized water, 0.5 parts of ammonium persulfate, and 0.1 part of bicarbonate to initiator tank b Potassium, stirred to dissolve;

[0098] 3) Prepare acrylamide monomer solution: add 15 parts of deionized water and 5 parts of acrylamide monomer, start the agitator, and mix well.

[0099] 4) Add 0.04 parts of sodium formaldehyde sulfox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com