Impact modifier formed by organo-silioxane crosslinked elastic polymer, and preparation method and application thereof

A technology of organosilane and improver, which is applied in the field of impact modifier and its preparation, can solve the problem that the brittle-ductile conversion performance cannot meet lower temperature and alloy, etc., and achieve soft structure, good impact resistance and excellent weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

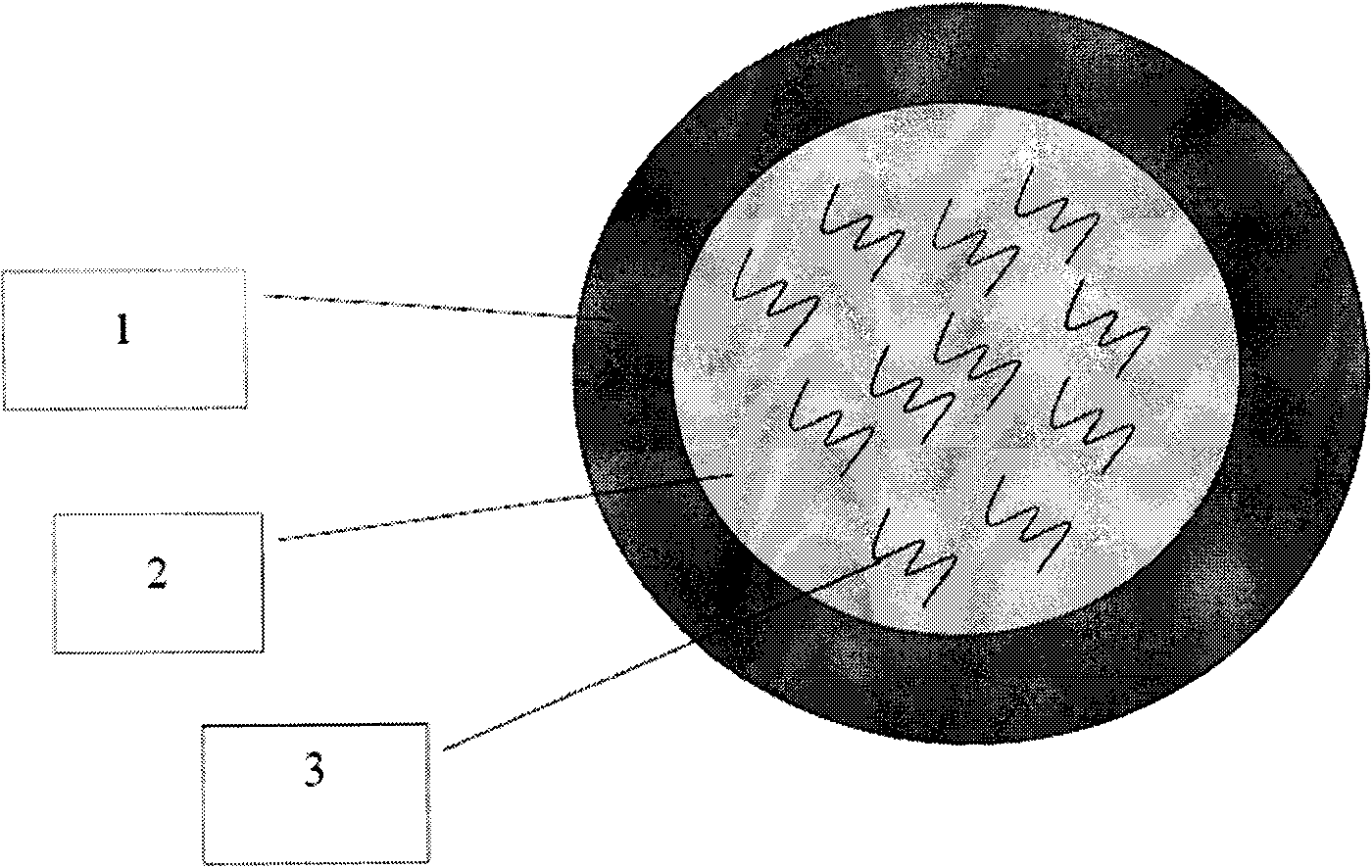

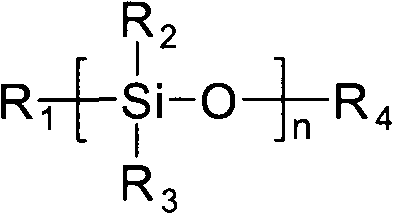

[0068] Example 1: This example describes a general method for preparing an organosiloxane crosslinked elastomeric polymer to form an impact modifier by an emulsion polymerization process.

[0069] 100 grams of water, 80 grams of butyl acrylate, 1 gram of methacrylic acid, 0.26 gram of sodium dodecylbenzene sulfonate, 0.4 gram of AEO9 (fatty alcohol polyoxyethylene emulsifier, purchased from Hebei Xingtai Kewang Auxiliary Co., Ltd. ) and 1 gram of methacryloxy-triethoxysilane are prepared into an emulsion, under the protection of nitrogen, first add 20 grams of emulsion, in 100 grams of 80 degrees containing 0.4 gram of ammonium persulfate, the peak temperature appears Finally, when the temperature returns to 80 degrees, add the remaining 160 grams of emulsion dropwise within three hours. After dropping, raise the temperature to 90 degrees and mature for 30 minutes, then drop the temperature to 80 degrees and continue to add 35 grams of methyl methacrylate dropwise within two ho...

Embodiment 2

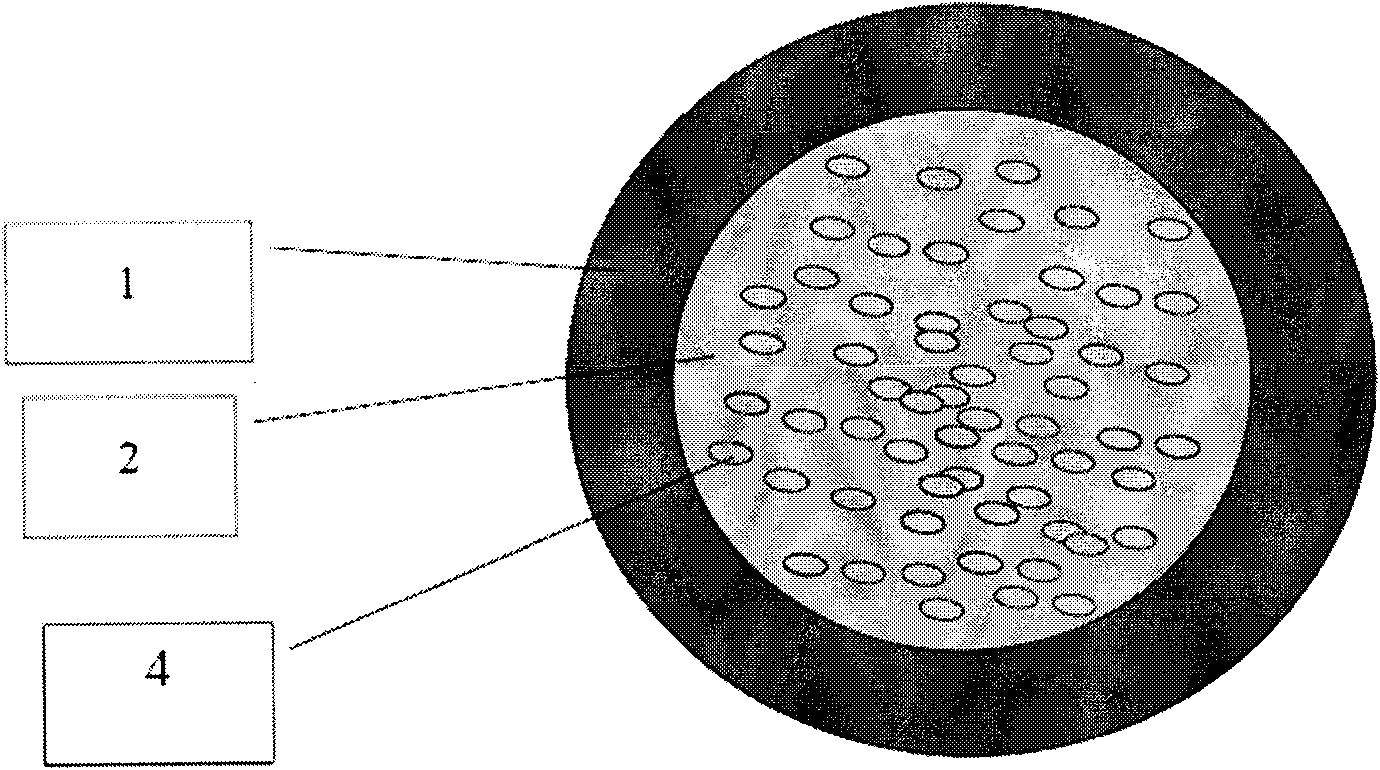

[0072] 100 grams of water, 80 grams of butyl acrylate, 0.26 grams of sodium dodecylbenzenesulfonate, 0.4 grams of AEO9 and 1 gram of methacryloxy-trimethoxy silicon, 2 grams of hydroxyvinyl silicone oil (polymerization degree 10, Vinyl content 3%) alkane is mixed with emulsion, under the protection of nitrogen, first add 20 grams of emulsion, in the water that contains 0.4 gram of ammonium persulfate in 100 grams of 80 degrees, after the peak temperature occurs, when the temperature returns to 80 degrees, Add dropwise the remaining emulsion in three hours. After dropping, heat up to 90°C and mature for 30 minutes. Cool down to 80°C and continue to dropwise add 35 grams of methyl methacrylate (alkali washing to remove the polymerization inhibitor) within two hours. After the addition is completed, add 0.1 gram of ammonium persulfate in 5 grams of aqueous solution, keep warm at 80°C for 2 hours, and filter the discharge. The average particle size was measured to be 350 nm.

[0...

Embodiment 3

[0075]100 grams of water, 60 grams of isooctyl acrylate, 3 grams of monolauryl maleate, 0.26 grams of sodium dodecylbenzenesulfonate, 0.4 grams of AEO9 and 20 grams of hydroxyvinyl silicone oil (polymerization degree 30, vinyl content 1 %), under the protection of nitrogen, first add 20 grams of emulsion, in 80 degrees 100 grams of water containing 0.4 grams of ammonium persulfate, after the peak temperature appears, when the temperature returns to 80 degrees, add the remaining emulsion dropwise within three hours , after dripping, heat up to 90 degrees and mature for 30 minutes, cool down to 80 degrees and continue to drop 50 grams of methyl methacrylate within two hours (alkali washing to remove the polymerization inhibitor). Ammonium sulfate in 5 grams of aqueous solution, at 80 °C for 2 hours, filtered and discharged. The average particle size measured was 200 nm.

[0076] Use sulfuric acid to adjust 500 grams of water to PH <= 2, add 0.1 gram of polyacrylamide, heat to 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com