Low-foam carrier brightening agent and using method thereof

A carrier brightener and brightener technology, which is applied in the field of electroplating, can solve the problems of main brightener damage, high brittleness of the coating, and limited application, and achieve the effects of reduced additive consumption, low additive consumption, and high current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The bath formula and process conditions of potassium chloride galvanizing process are as shown in table 2:

[0045] Table 2

[0046]

[0047] Softener composition: 10% low-foam carrier brightener (including 0.5% non-ionic silicone surfactant, 9.5% isomeric tridecyl alcohol polyoxyethylene ether, EO=100), 6% sodium benzoate, 5% methanol , the balance is water;

[0048]Brightener composition: 3% o-chlorobenzaldehyde, 5.3% low-foam carrier brightener (including 0.3% non-ionic silicone surfactant, 5% isomeric tridecyl polyoxyethylene ether, EO=50), 5% % methanol, the balance is water;

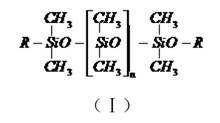

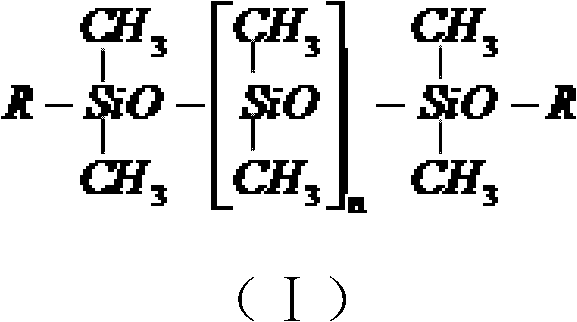

[0049] Wherein, the structural formula of the above-mentioned nonionic silicone surfactant is:

[0050]

[0051] R=O(C 2 h 4 O) a (C 3 h 6 O) b (C 2 h 4 O) c CH 3 , a=16, b=10, c=15; n=7.

[0052] Adopt the formula of potassium chloride galvanized plating solution of embodiment 1 and process condition to carry out Hobster's tank test, plating solution does not carry out c...

Embodiment 2

[0054] The bath formulation and process conditions of potassium chloride galvanizing process are as shown in table 3:

[0055] table 3

[0056]

[0057] Softener composition: 10.8% low-foam carrier brightener (including 0.8% non-ionic silicone surfactant, 10% isomeric tridecyl alcohol polyoxyethylene ether EO=100), 7% sodium benzoate, 6% ethanol, The remainder is water;

[0058] Brightener composition: 4% benzylidene acetone, 6.4% low-foam carrier brightener (including 0.4% non-ionic silicone surfactant, 6% isomeric tridecyl polyoxyethylene ether EO=50), 6 % ethanol, the balance is water;

[0059] Wherein, the structural formula of the above-mentioned nonionic silicone surfactant is:

[0060]

[0061] R=O(C 2 h 4 O) a (C 3 h 6 O) b (C 2 h 4 O) c CH 3 , a=16, b=10, c=15; n=8.

[0062] Adopt the formula of potassium chloride galvanized plating solution of embodiment 2 and process condition to carry out Huo's tank test, plating solution does not carry out comp...

Embodiment 3

[0064] The bath formula and process conditions of potassium chloride galvanizing process are as shown in table 4:

[0065] Table 4

[0066]

[0067] Softener composition: 10% low-foam carrier brightener (including 0.7% non-ionic silicone surfactant, 9.3% octylphenol polyoxyethylene ether EO=100), 8% sodium benzoate, 8% ethylene glycol ether , the balance is water;

[0068] Brightener composition: 5% o-chlorobenzaldehyde and benzylidene acetone reactant, 10% low-foam carrier brightener (including 0.5% non-ionic silicone surfactant, 9.5% lauryl alcohol polyoxyethylene ether EO =50), 7% ethylene glycol ether, and the balance is water;

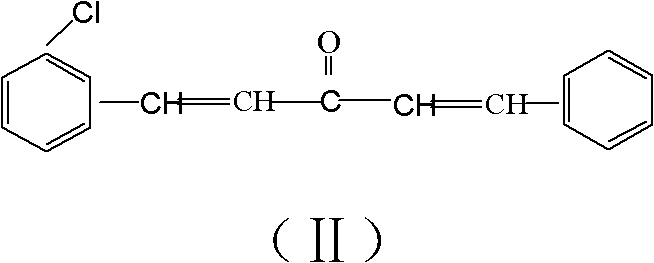

[0069] Wherein, the structural formula of o-chlorobenzaldehyde and benzylidene acetone reactant is:

[0070]

[0071] The structural formula of nonionic silicone surfactant is:

[0072]

[0073] R=O(C 2 h 4 O) a (C 3 h 6 O) b (C 2 h 4 O) c CH 3 , a=16, b=10, c=15; n=9.

[0074] Adopt the formula of potassium chloride galvan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com