Indium-based sulfide composite photocatalyst and preparation method thereof

A technology of sulfide and composite light, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of low hydrogen production of ternary indium-based sulfides, and achieve good product dispersion, The effect of low energy consumption and good visible light response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

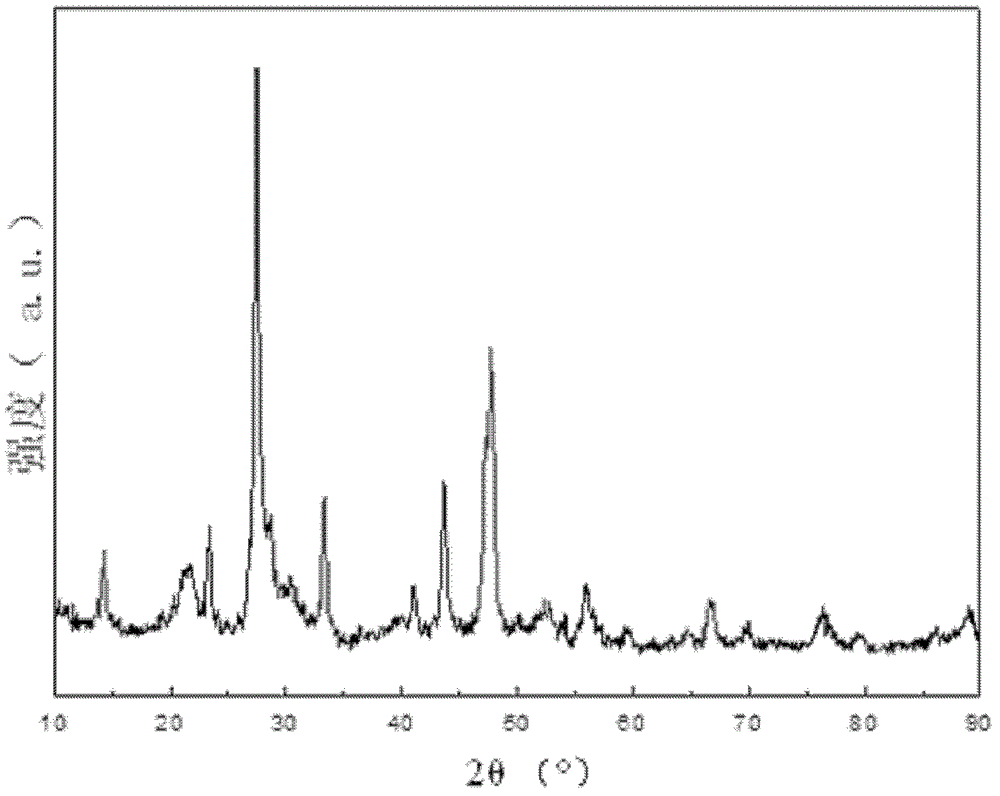

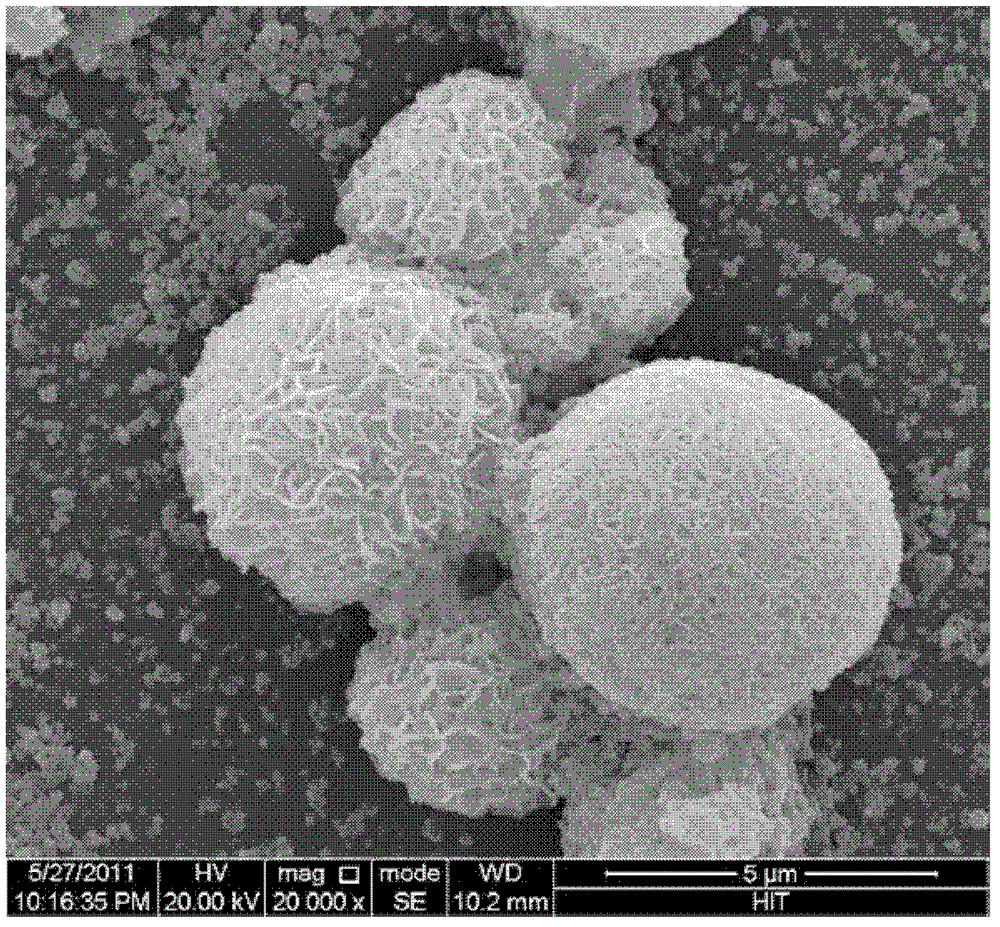

[0014] Embodiment 1: The indium-based sulfide composite photocatalyst of this embodiment is made by a one-step hydrothermal method using cadmium salt, zinc salt, indium salt and sulfur source compound, wherein Cd 2+ with Zn 2+ The molar ratio of Cd is 0.11~0.43:1, Cd 2+ with Zn 2+ The sum of the number of moles and In 3+ The molar ratio of Cd is 1:2, Cd 2+ with Zn 2+ The ratio of the sum of the moles of the sulfur source compound to the moles of the sulfur source compound is 1:8.

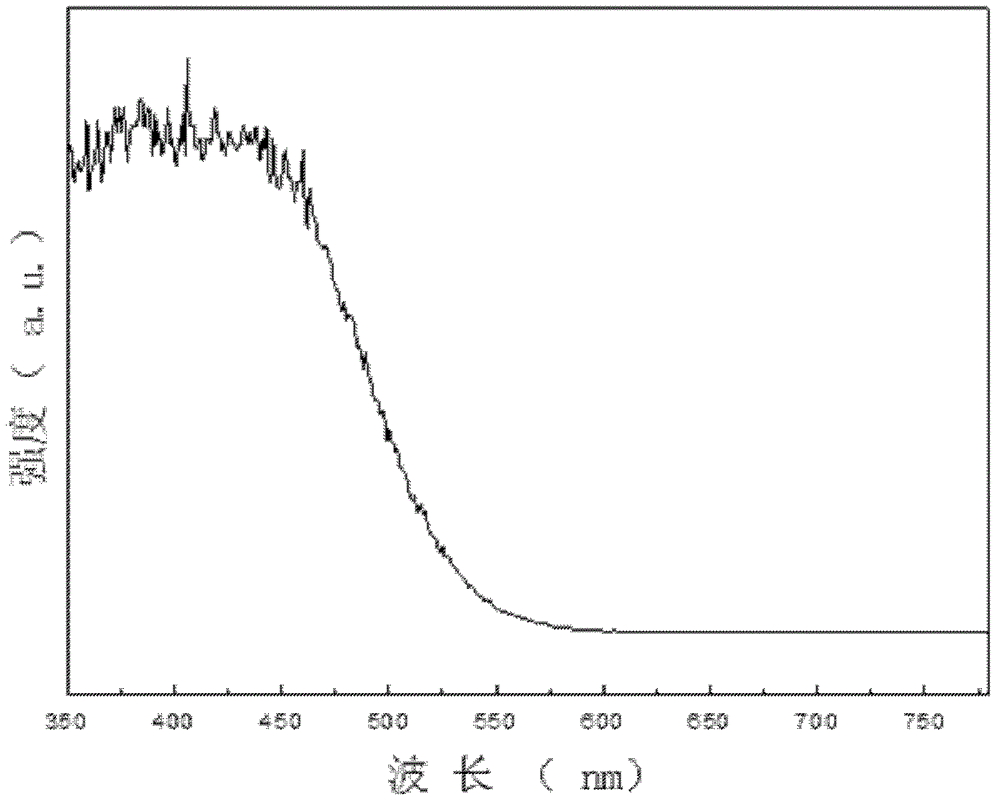

[0015] The indium-based sulfide composite photocatalyst of this embodiment has better visible light response, and has a strong absorption at about 550nm, and at the same time, the indium-based sulfide composite photocatalyst exhibits higher performance of splitting water to produce hydrogen under visible light , under the light irradiation of λ>400nm, the hydrogen production amount reached 32000μmol·h -1 g -1 ~37000μmol·h -1 g -1 , and the activity of the catalyst did not decrease significa...

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is that Cd 2+ with Zn 2+ The molar ratio is 0.15~0.40:1. Others are the same as in the first embodiment.

[0017] More preferred Cd in this embodiment 2+ with Zn 2+ The molar ratio is 0.20:1.

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the cadmium salt is cadmium chloride, cadmium nitrate, cadmium sulfate or cadmium acetate. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com