Hydrophobically associating water-soluble polymer (HAWSP) oil displacement agent and synthesis method thereof

A hydrophobic association and polymer technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems affecting the application range of HAWP, produce precipitation, and reduce viscosity, and achieve enhanced oil recovery and viscosity increase. , the effect of enhancing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation of DNDA monomer

[0024] Add 42.3g of oleic acid into the reactor, slowly add 10.2g of phosphorus trichloride under stirring, the feeding temperature is controlled at 10-15°C, after the addition is completed, the temperature is raised to 55°C, and the lower layer and the upper layer are separated after 4 hours of heat preservation reaction. Unreacted phosphorus trichloride was removed by evaporation to obtain oleoyl chloride with a yield of 99.0%. Dilute 12.46 g of oleoyl chloride obtained in the previous step with a dichloromethane solvent and put it into a constant pressure dropping funnel for use, then add 3.63 g of diallylamine to a 250 ml dry three-necked flask, dilute with a dichloromethane solvent, and then Add 3.79 g of triethylamine and 0.02 g of hydroquinone, and slowly add the oleoyl chloride solution to be used dropwise in an ice-water bath with constant stirring, and control the dropping for 1 hour. After dripping, it was reac...

Embodiment 2

[0025] Embodiment 2: the synthesis of terpolymer AM / NaAA / DNDA

[0026] According to the ratio in Table 1, first weigh acrylic acid and dilute it with 10g of deionized water, slowly add NaOH in an ice-water bath, and cool to room temperature; add the DNDA monomer prepared above into a 250ml three-necked flask, and then add OP-10 to emulsify and 10g of deionized water, stir well until the emulsification is complete, add AM, then add sodium acrylate solution, adjust the pH of the system to 8 with NaOH solution, and pass nitrogen for 20 minutes; then add initiator sodium bisulfite and ammonium persulfate solution, Continue to pass N 2 After reacting for 10 minutes at a constant temperature of 40°C for 12h, washing with absolute ethanol, precipitation and crushing, and drying at a constant temperature of 40°C, the AM / NaAA / DNDA ternary polymer was prepared.

[0027] Table 1 Addition amount of ternary polymer synthetic drugs

[0028]

[0029]

Embodiment 3

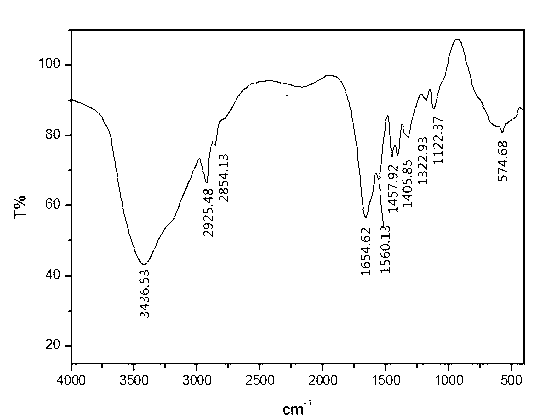

[0030] Embodiment 3: AM / NaAA / DNDA terpolymer structure characterization

[0031] The infrared spectrogram of the ternary polymer AM / NaAA / DNDA synthesized by embodiment 2 is as follows figure 1 shown. It is known from the figure that -C(O)NH 2 The stretching vibration peaks are at 3436.53cm -1 , the -C=O stretching vibration peak is at 1654.62cm -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com