Red fluorescent powder for light-emitting diodes and preparation method thereof

A technology of red phosphor powder and light emitting diode, applied in the field of LED light source, can solve the problems of unsuitable general lighting field, high color temperature, elegant color coordinates, etc., and achieve the effects of improving lighting and display quality, improving color rendering, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

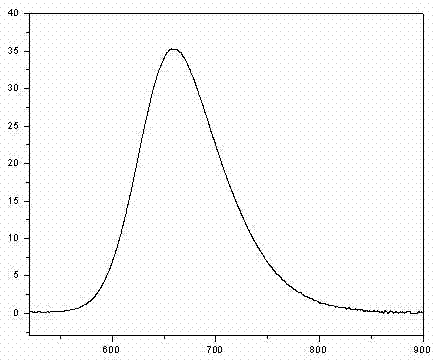

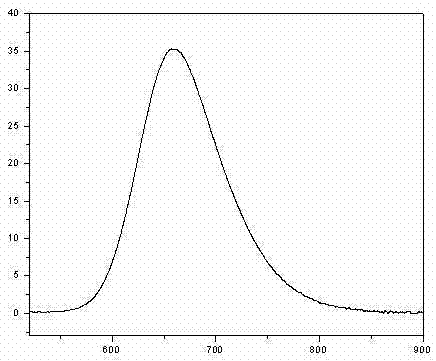

[0013] To prepare a red phosphor for LED: weigh 0.323 mol of Ca 3 N 2 , 0.02 mole of EuN, 0.83 mole of Si 3 N 4 , 0.01 mole of NH 4 F. Mix well. The reaction was performed for 10 hours at 1600 degrees Celsius at 20 atmospheres in nitrogen. Cool to room temperature, crush, grind, go through a 200 mesh screen, wash, and dry at 120 degrees Celsius for 10 hours. The red phosphor for this kind of light-emitting diode is obtained, and its emission spectrum is as follows figure 1 Shown.

Embodiment 2

[0015] Prepare a red phosphor for LED: weigh 0.323 mole of Sr 3 N 2 , 0.02 mole of EuN, 0.83 mole of Si 3 N 4 , 0.01 mole of NH 4 F. Mix well. The reaction was carried out for 10 hours at 1350 degrees Celsius at 20 atmospheres in nitrogen. Cool to room temperature, crush, grind, go through a 200 mesh screen, wash, and dry at 120 degrees Celsius for 10 hours. The red phosphor for this kind of light-emitting diode is obtained, and its emission spectrum is as follows figure 1 Shown.

Embodiment 3

[0017] To prepare a red phosphor for LED: weigh 0.2 mole of Ca 3 N 2 , 0.13 mole of Sr 3 N 2 , 0.02 mole of EuN, 0.83 mole of Si 3 N 4 , 0.01 mole of NH 4 Cl. Mix well. The reaction was carried out for 8 hours at 1700°C under 10 atmospheres in nitrogen. Cool to room temperature, crush, grind, go through a 200 mesh screen, wash, and dry at 120 degrees Celsius for 10 hours. The red phosphor for this kind of light-emitting diode is obtained, and its emission spectrum is similar figure 1 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com