Water-based cleaning-free flux for lead-free welding flux and preparation method thereof

A lead-free solder, water-based technology, applied in the direction of welding equipment, welding/cutting media/materials, welding media, etc., can solve the problems of reducing flux activity, flux activator volatilization, and insulation performance reduction, so as to improve activation performance, surface tension reduction, and wettability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

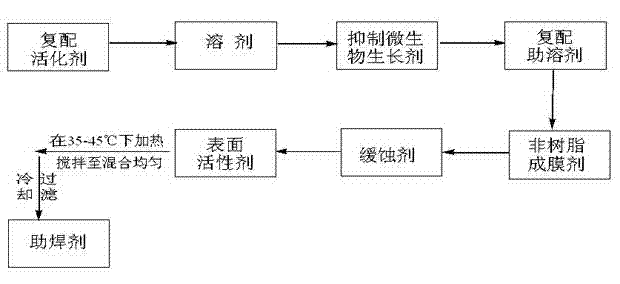

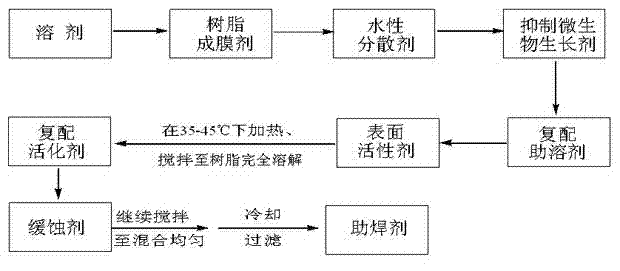

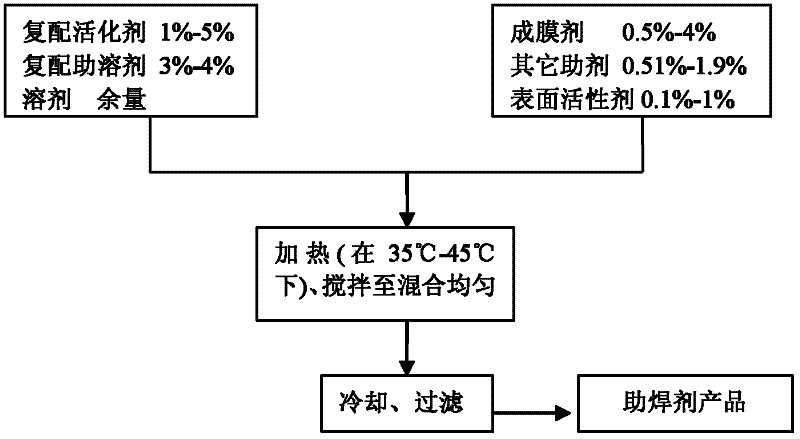

Method used

Image

Examples

Embodiment 1

[0035] Add 0.3% of itaconic acid, 0.4% of glutaric acid and 0.3% of lactic acid, the balance of self-distilled deionized water, 0.6% of isopropanol, 1% of ethylene glycol, 1% of ethylene glycol butyl ether and Ethylene glycol ether 1%, polyethylene glycol 1000 0.62%, hydrazine hydrate 0.01%, DP-205 0.1%; after adding each component, stir at 35-45°C until completely dissolved and mixed evenly, after the mixture is cooled Filter to obtain flux.

Embodiment 2

[0037] Add 0.8% of succinic acid, 0.4% of triethanolamine and 0.4% of lactic acid, the balance of self-distilled deionized water, 1% of isopropanol, 1% of diethylene glycol, 1% of dipropylene glycol dimethyl ether and ethyl alcohol in the reaction vessel. Diol butyl ether 1%, glycerin 0.74%, hydrazine hydrate 0.03%, benzotriazole 0.01%, AP2590 0.08% and OP-10 0.46%; after adding each component, stir at 35-45°C until complete Dissolve and mix evenly, and filter to obtain flux after the mixture is cooled.

Embodiment 3

[0039] Add 1% succinic acid, 0.5% triethanolamine and 0.75% dl-malic acid successively in the reaction vessel, and the balance of self-evaporating deionized water,

[0040] Isopropyl Alcohol 0.64%, Triethylene Glycol 1.2%, Propylene Glycol Methyl Ether 1.2%, Ethylene Glycol Butyl Ether 1.2%, Polyethylene Glycol 2000 0.5%,

[0041] Hydrazine hydrate 0.04%, OP-10 0.1%; After adding each component, stir at 35-45°C until completely dissolved and mixed evenly. After the mixture is cooled, filter to obtain flux.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com