Asymmetrical polyurethane/nano TiO2 thin film wound dressing and preparation method thereof

A wound dressing and polyurethane technology, applied in the field of medical wound dressing and its preparation, can solve the problems of physiological toxicity, inability to fully meet the use requirements of medical wound dressing, secondary injury of newborn tissue, etc., and achieve the effect of accelerating the healing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

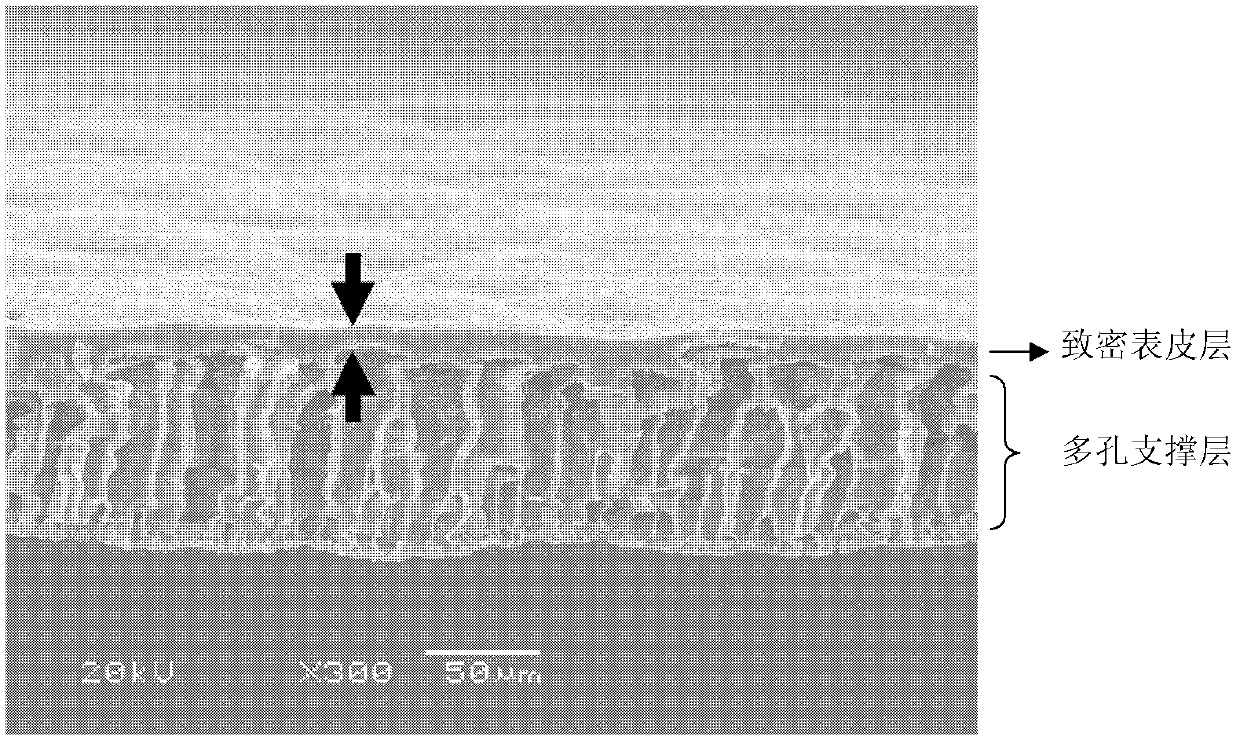

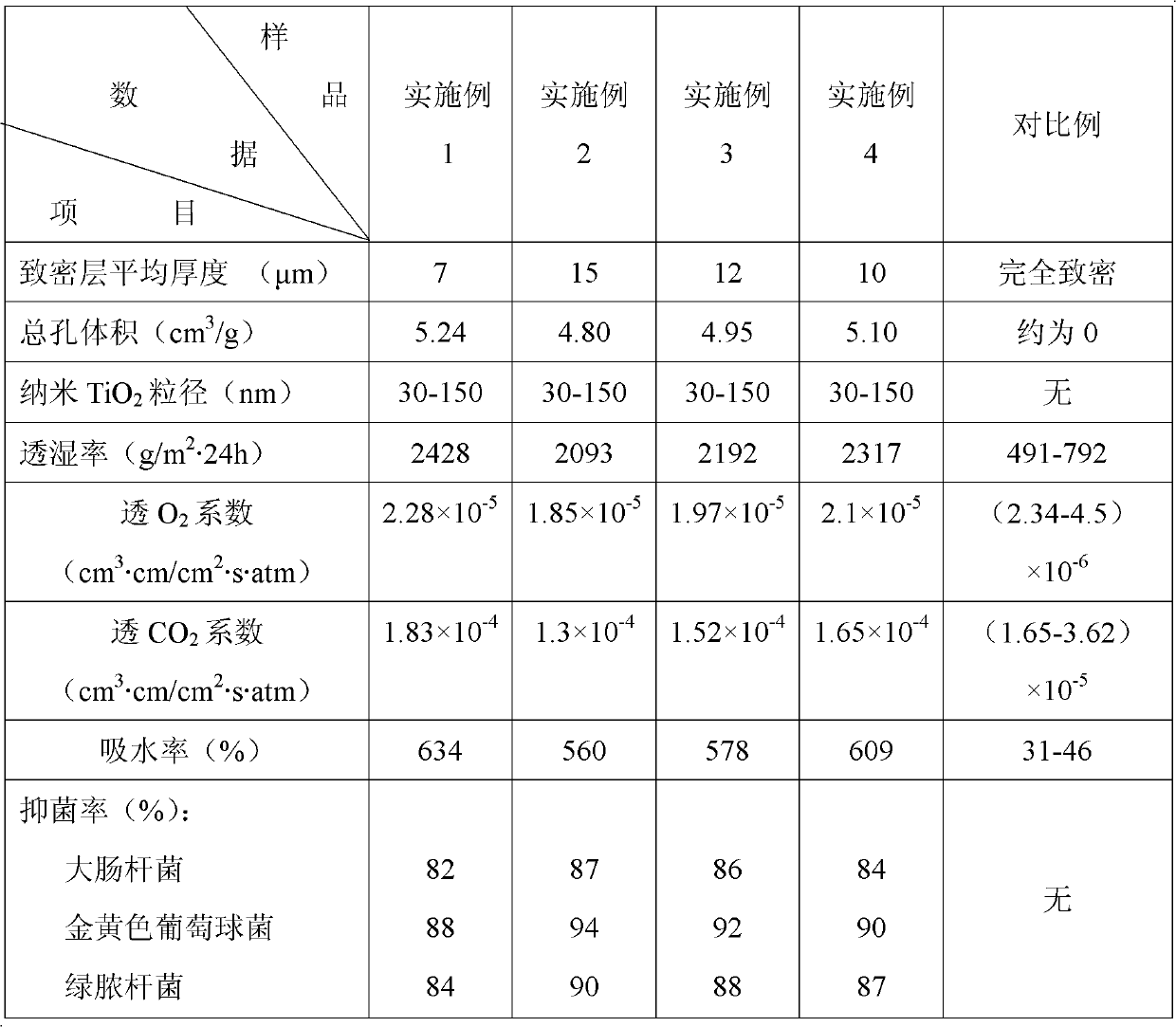

[0025] Add 1 part of ethyl titanate dropwise to a mixed solution prepared by 0.2 parts of diethanolamine and 15 parts of methyl ethyl ketone, and stir at 30°C for 25 minutes, then add 100 parts of the obtained yellow transparent solution with a solid content of 25 wt%. MDI solvent-based polyurethane solution, and continue to oscillate with ultrasonic frequency 35KHz at 30°C for 20 minutes, defoaming for later use;

[0026] Coat the prepared mixture solution on a silicon-based release paper with a coating thickness of 150 μm, and immediately heat it at 40°C for 2 minutes to evaporate the solvent on the surface of the liquid film to form a dense skin layer, and then immerse it as a whole in a pH value 4.5 Coagulate in deionized water for 30 minutes, peel off the coagulated and formed film dressing from the release paper, then fully wash with deionized water and dry at 40°C.

Embodiment 2

[0028] Add 9 parts of n-butyl titanate dropwise into the mixed solution prepared by 10.5 parts of acetylacetone and 15 parts of N,N-dimethylformamide, and stir at 35°C for 45 minutes, then add the obtained yellow transparent solution to 200 parts of a hydrogenated MDI solvent-based polyurethane solution with a solid content of 40 wt%, and continue to vibrate with a frequency of 30KHz ultrasonic waves for 30 minutes at 35°C, and defoam for subsequent use;

[0029] The prepared mixture solution was coated on chromium complex release paper with a coating thickness of 150 μm, and immediately heated at 70°C for 10 minutes to evaporate the solvent on the surface of the liquid film to form a dense skin layer, and then immerse it as a whole in a 35wt% N, N-dimethylformamide was coagulated in deionized water with a pH value of 6.0 for 5 minutes, and the film dressing after coagulation was peeled off from the release paper, then fully washed with deionized water and dried at 70°C Just d...

Embodiment 3

[0031] Add 6 parts of n-butyl titanate dropwise to the mixed solution prepared by 6.2 parts of triethanolamine and 5 parts of N,N-dimethylacetamide, and stir at 30°C for 60 minutes, then add the obtained yellow transparent solution to 200 parts of IPDI solvent-based polyurethane solutions with a solid content of 35wt%, and continue to vibrate with ultrasonic waves at a frequency of 45KHz for 20 minutes at 30°C, and defoam for subsequent use;

[0032] Coat the prepared mixture solution on polymethylpentene release paper with a coating thickness of 150 μm, and immediately heat it at 60°C for 8 minutes to evaporate the solvent on the surface of the liquid film to form a dense skin layer, and then immerse it as a whole Containing 25wt% N,N-dimethylacetamide, coagulate in deionized water with a pH value of 5.5 for 10 minutes, peel off the solidified and formed film dressing from the release paper, then fully wash with deionized water and place at 30°C Just dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com