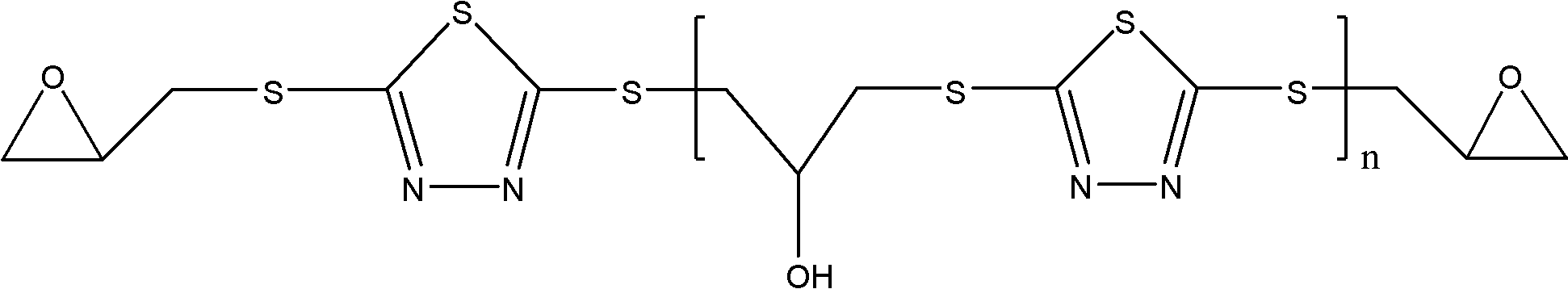

Sulphur-containing optical epoxy resin and preparation method thereof

A technology of epoxy resin and sulfur optics, which is applied in the field of optical epoxy resin containing sulfur and high refractive index and its synthesis. High efficiency and transparent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

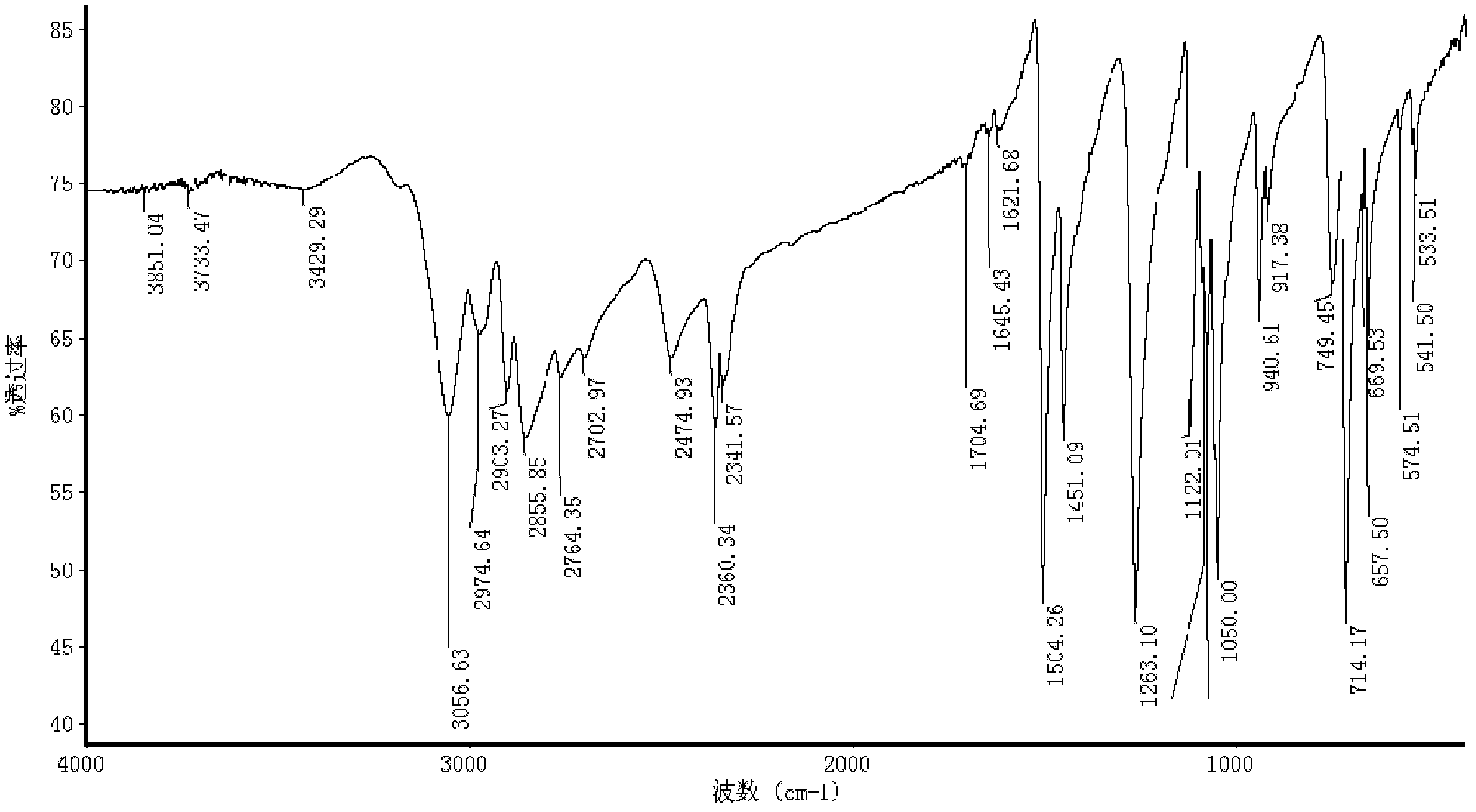

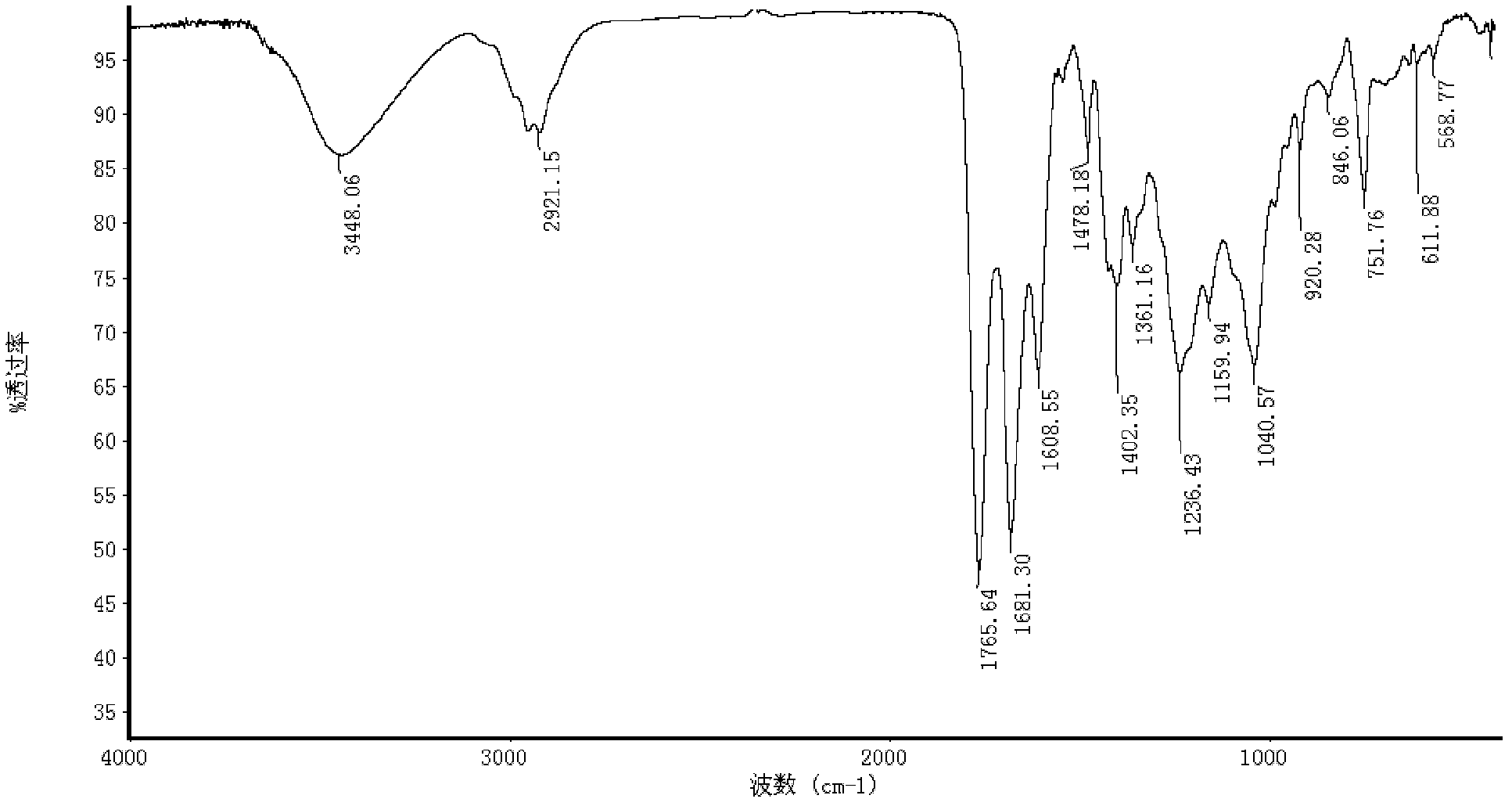

Embodiment 1

[0027] Add ECH (0.2 mol) and DMTD (0.1 mol) into a nitrogen-protected flask equipped with a stirring device, a thermometer and a reflux condenser (the flask needs a water bath), and stir and dissolve in an ice-water bath. And add 10% (mass concentration) sodium hydroxide solution containing 0.001 mol of alkali. After the DMTD was completely dissolved, the temperature was raised to 50°C, and the reaction was carried out for 2 hours. Recover the unreacted ECH by distillation at 120°C; finally cool down to 50°C; add 0.2mol methyl isobutyl ketone, keep the reaction temperature at 50°C, and gradually dropwise add sodium hydroxide solution with a mass concentration of 10%. The amount of sodium hydroxide added is 0.2mol, and the addition is completed within 1h; then keep warm for 0.5h. Stop stirring and discharge. Put the material in a separatory funnel, add deionized water, shake, separate and remove the water layer. Then add deionized water, repeat the liquid separation several ...

Embodiment 2

[0032] Add ECH (2 mol) and DMTD (0.1 mol) into a nitrogen-protected flask equipped with a stirring device, a thermometer and a reflux condenser (the flask needs a water bath), and stir and dissolve in an ice-water bath. And add 10% sodium hydroxide solution containing 0.001 mol of alkali. After the DMTD was completely dissolved, the temperature was raised to 50°C, and the reaction was carried out for 2 hours. Recover the unreacted ECH distillation under the condition of 120 ℃; finally cool down to 50 ℃; add 0.2mol methyl isobutyl ketone, keep the reaction temperature at 50 ℃, gradually dropwise add the sodium hydroxide solution whose mass concentration is 10%, The amount of sodium hydroxide added is 0.2mol, and the addition is completed within 1h; then keep warm for 0.5h. Stop stirring and discharge. Put the material in a separatory funnel, add deionized water, shake, separate and remove the water layer. Then add deionized water, repeat the liquid separation several times u...

Embodiment 3

[0034] Add ECH (1mol) and DMTD (0.1mol) into a nitrogen-protected flask equipped with a stirring device, a thermometer, and a reflux condenser (the flask needs a water bath), and stir and dissolve in an ice-water bath. And add 10% 1 sodium hydroxide solution containing 0.001 mol of alkali. After the DMTD was completely dissolved, the temperature was raised to 50°C, and the reaction was carried out for 2 hours. Recover the unreacted ECH distillation under the condition of 100°C; finally cool down to 50°C; add 0.2mol methyl isobutyl ketone, keep the reaction temperature at 50°C, and gradually add a mass concentration of 10% sodium hydroxide solution, The amount of sodium hydroxide added is 0.2mol, and the addition is completed within 1h; then keep warm for 0.5h. Stop stirring and discharge. Put the material in a separatory funnel, add deionized water, shake, separate and remove the water layer. Then add deionized water, repeat the liquid separation several times until the org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com