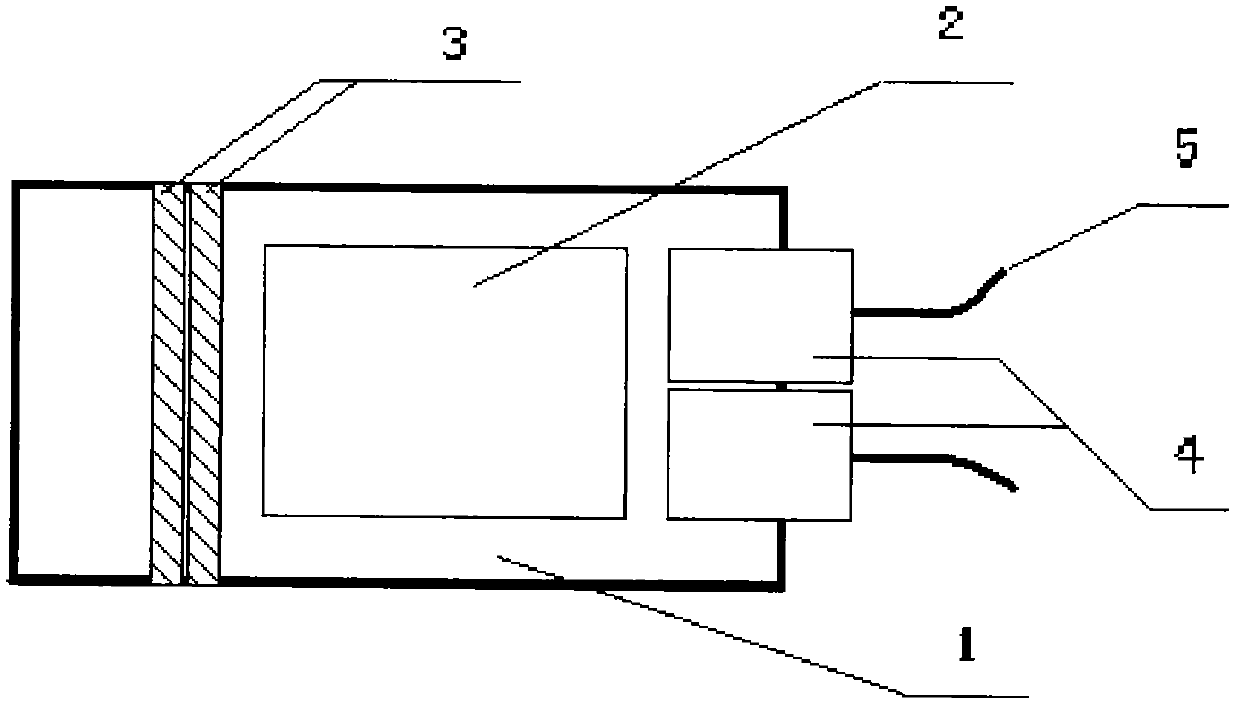

Method and sample shelf for X-ray diffraction in-situ test

An in-situ test and X-ray technology, applied in the preparation of test samples, material analysis using radiation diffraction, etc., can solve the problems of electrolyte volatilization, single electrode active material, etc., and achieve simple processing, easy acquisition, and easy Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

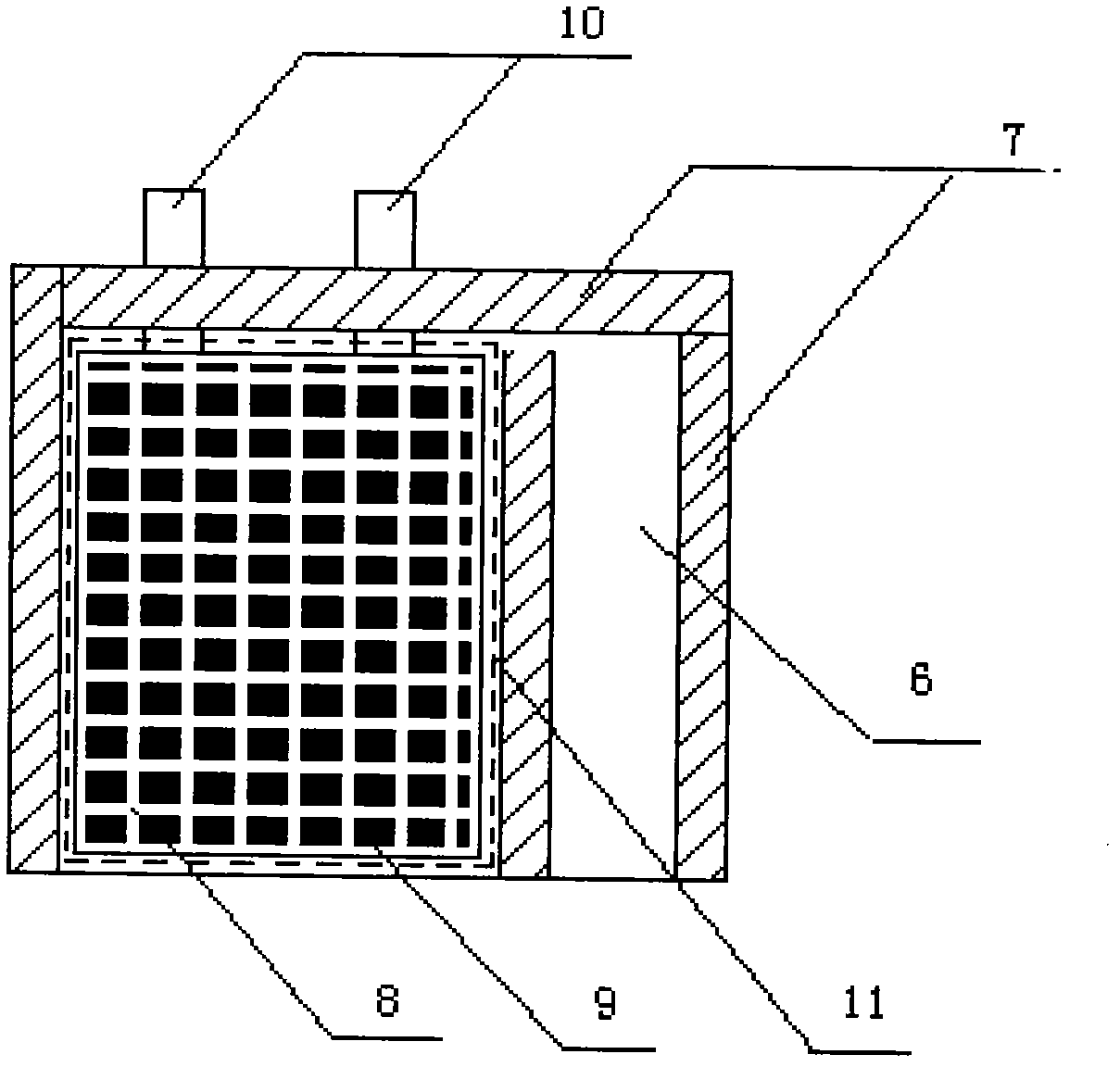

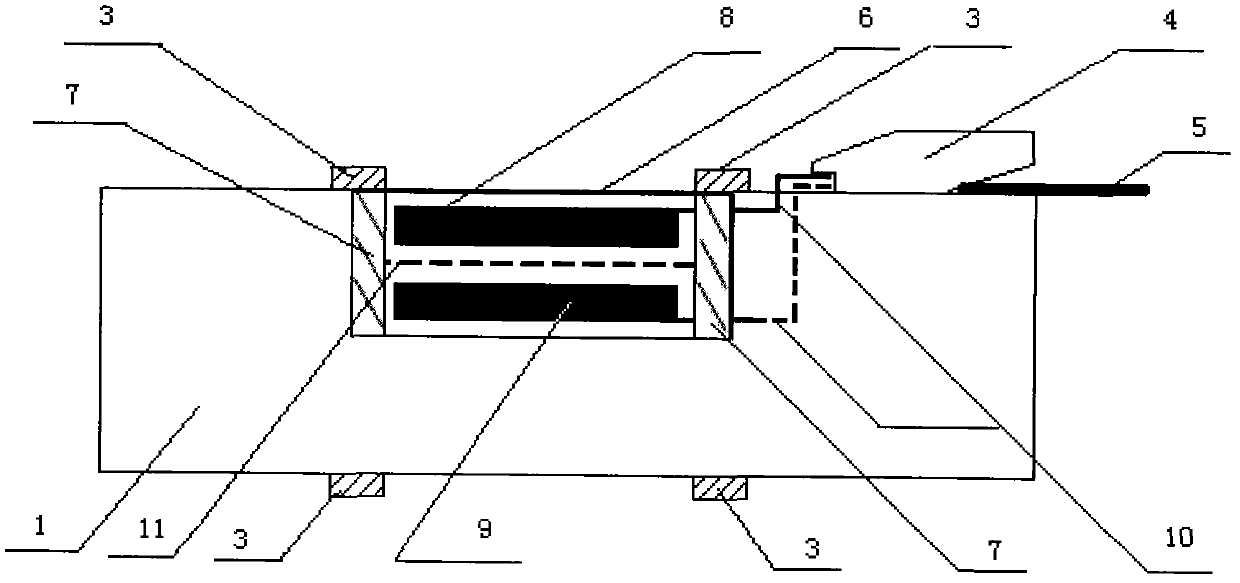

Embodiment 1

[0031] According to the above method, the processing is completed to manufacture the X-ray diffraction in-situ test sample holder. Make a slurry with LiNi0.33Mn0.33Co0.33O2 as the cathode active material and natural graphite as the anode active material, and apply the slurry on the aluminum foil with a porosity of 40% and the copper foil with a porosity of 35% according to the above method, and roll Made into pole pieces. Cut the cathode pole piece into small pieces of 33mm*48mm, cut the anode pole piece into small pieces of 34mm*50mm, and keep the tabs. Cut the isolation film into a small piece of 36mm*52mm, stack the above three, and fix it with positioning glue. Wrap the prepared bare cell with 0.025mm polyethylene film, seal the top and one side, inject electrolyte, and vacuum seal the other side after standing for 1 hour. Use a small current such as 0.5mA to charge the battery for the first time and form it. If there is gas that affects the flatness of the surface of t...

Embodiment 2

[0034] According to the above method, the processing is completed to manufacture the X-ray diffraction in-situ test sample holder. Made with LiCoO 2 As the cathode active material, use natural graphite as the slurry of the anode active material, and apply it on the aluminum foil with a porosity of 50% and the copper foil with a porosity of 30% according to the above method, and then roll it into a pole piece . Cut the cathode pole piece into small pieces of Ф = 10mm, cut the anode pole piece into small pieces of Ф = 12mm, and keep the tabs. Cut the isolation film into a small piece of Ф=16mm, stack the above three, and fix it with positioning glue. Wrap the prepared bare cell with a 0.040mm polypropylene film, seal the top and one side of the packaging area 7, inject electrolyte, and vacuum seal the other side after standing for 1 hour. Use a small current such as 0.1mA to charge the battery for the first time and form it. If there is gas that affects the flatness of the s...

Embodiment 3

[0036] According to the above method, the processing is completed to manufacture the X-ray diffraction in-situ test sample holder. Make a slurry with graphite as the active material of the electrode to be tested, and apply it on copper foil with a porosity of 60% according to the above method, and then roll it into a pole piece, and cut it into Ф = 10mm Small pieces, keep the tabs 10. Using a metal lithium sheet as a reference electrode, cut it into small pieces with Ф=12mm, and press them tightly with the tab 10. Cut the isolation film 11 into a small piece with Ф=16mm, stack the above three, and fix it with positioning glue. Wrap the prepared bare cell with a 0.1mm polystyrene film, seal the top and one side of the packaging area 7, and inject electrolyte, and then vacuum-seal the other side after standing for 1 hour, and pass Clamping and standing improves the flatness of the surface. Clamp the reshaped battery cell test side up on the charging and discharging test chann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com