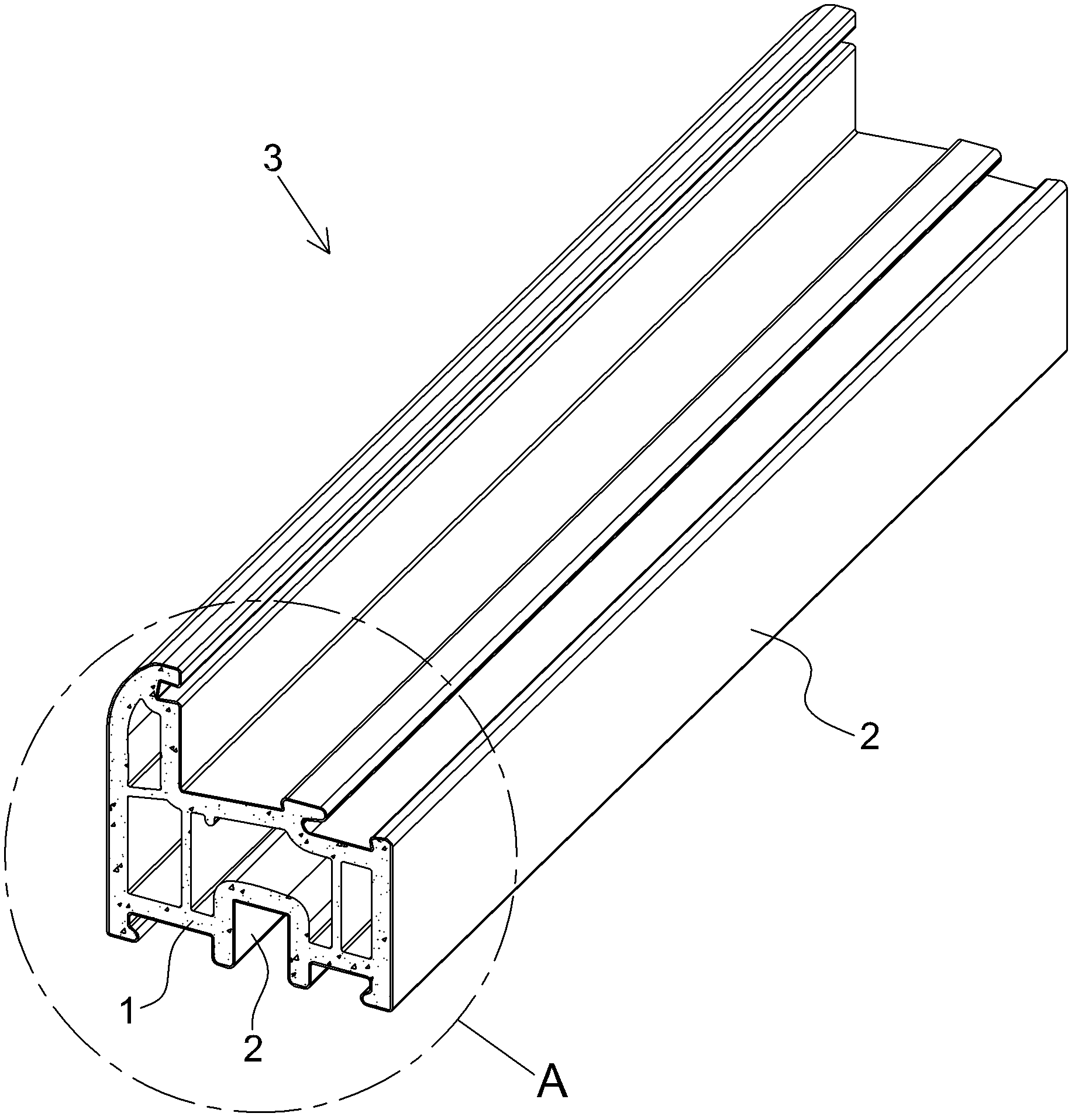

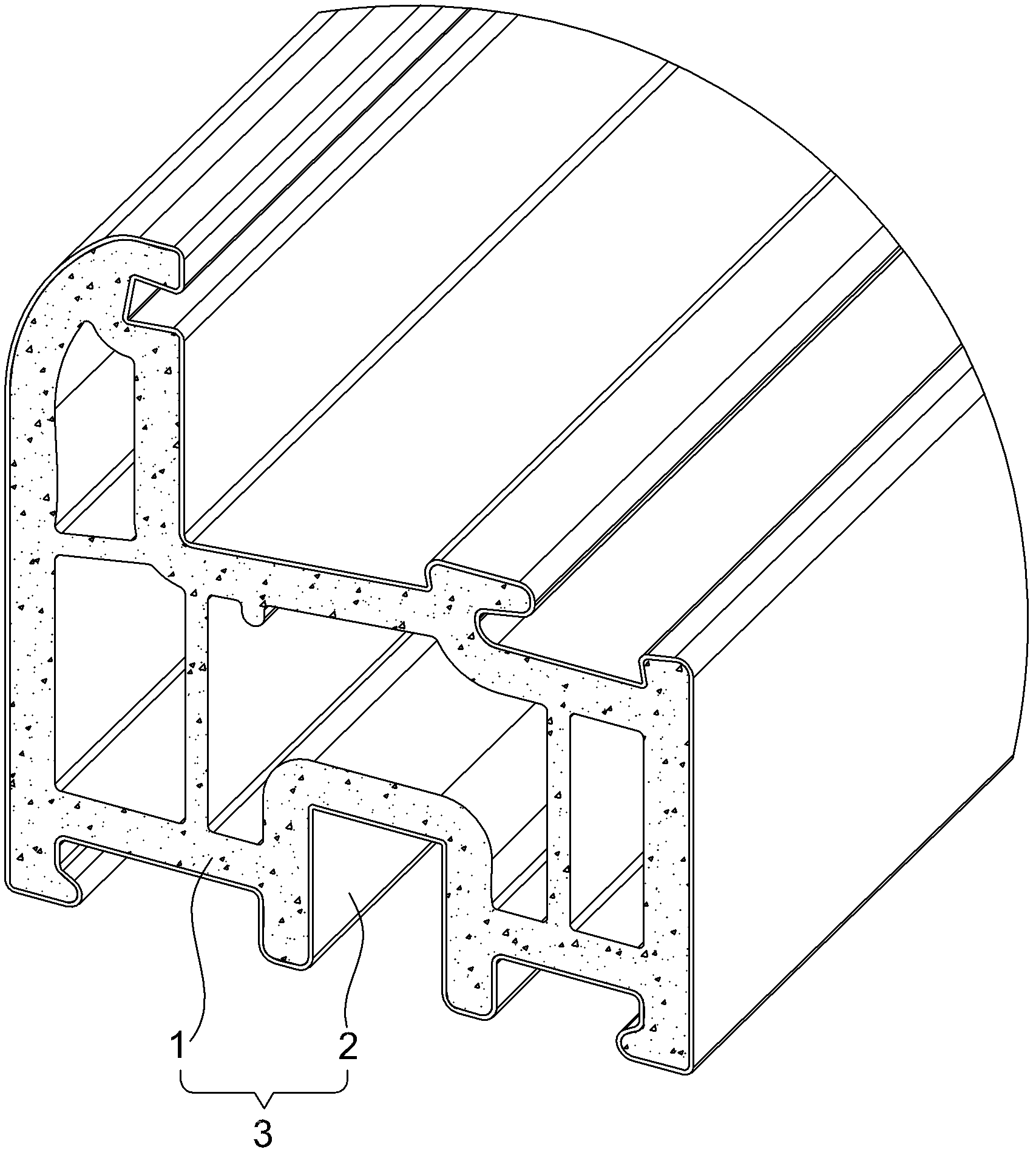

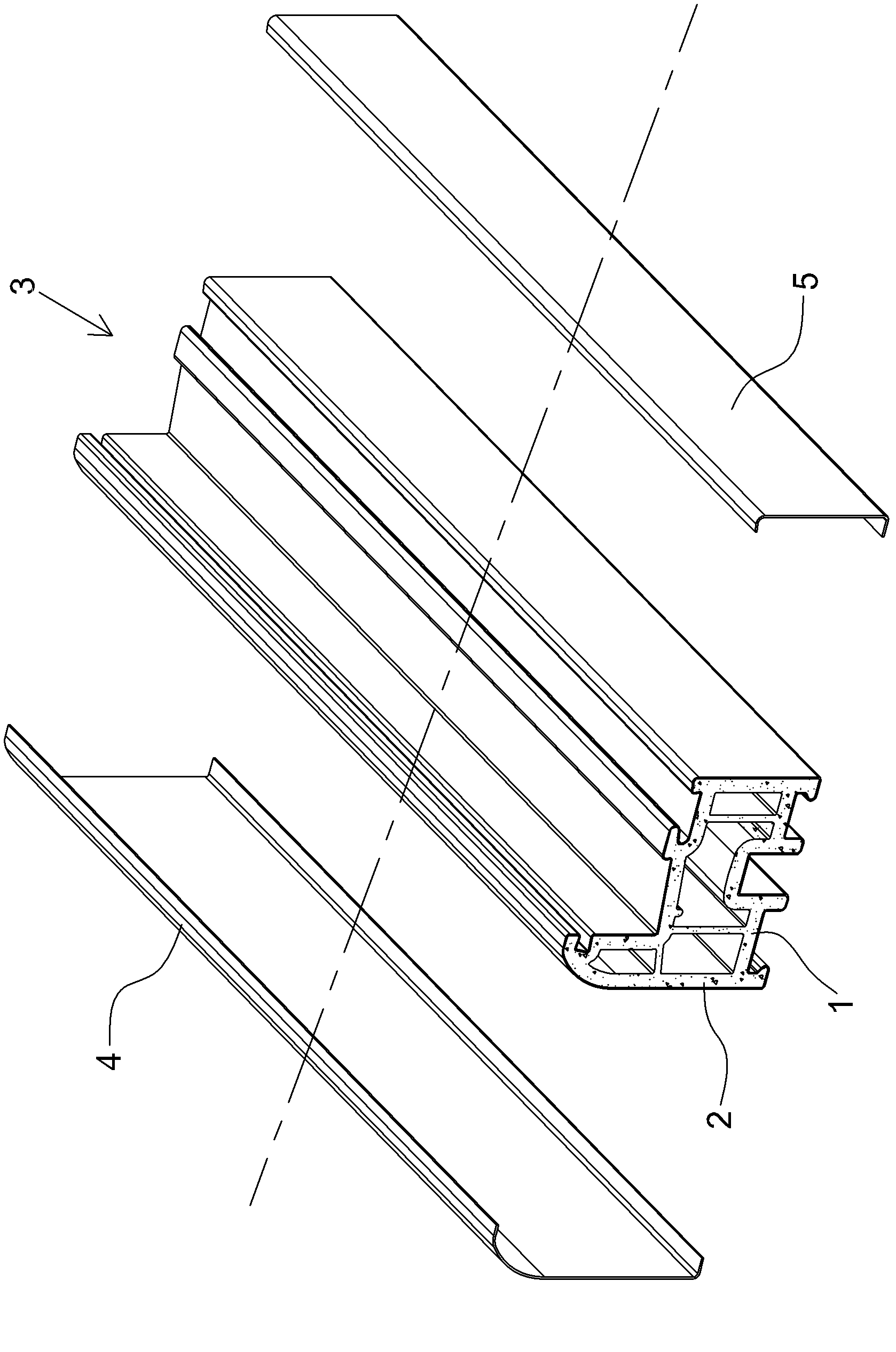

Production method of aluminum-plastic wood fiber composite profile

A technology for composite profiles and production methods, which is applied in the field of aluminum-plastic wood fiber composite profiles, can solve problems such as poor weather resistance, affecting the integrity and quality of profiles, and shortened service life. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The present invention is a method for producing aluminum-plastic-wood fiber composite profiles, including the following steps:

[0051] Step 1. Material preparation:

[0052] (1) Use polypropylene PP (Polypropylene) thermoplastic waste plastic as the main material. The main material can be recycled plastic bottles, plastic tubes, plastic cups and other plastic containers. The material is polypropylene PP (Polypropylene). The plastic bottles, plastic cylinders, and plastic cups are crushed by a crusher, and then extruded by an extruder into uniform spherical plastic particles (as the main material) for use. The spherical diameter of the plastic particles is 2mm.

[0053] (2) Choose plant fiber as auxiliary material, plant fiber is sawdust, use a roller to crush the sawdust into a 40-mesh flour noodle,

[0054] (3) Purchase 300 mesh mineral powder as filler, the mineral powder is glass fiber powder,

[0055] (4) Select chemical reagents with coupling effect as additives, and the a...

Embodiment 2

[0069] The present invention is a production method of aluminum-plastic-wood fiber composite profile, including the following steps:

[0070] Step 1. Material preparation:

[0071] (1) Use polyethylene PE (Polyethylene) material waste plastic as the main material. The main material can be recycled plastic bottles, plastic tubes, plastic cups and other plastic containers. The materials are all polyethylene PE (Polyethylene). Plastic bottles, plastic cylinders, and plastic cups are crushed by a crusher, and then extruded by an extruder into uniform spherical plastic particles (as the main material) for use. The diameter of the plastic particles is 3mm.

[0072] (2) Select plant fiber as auxiliary material, plant fiber is bamboo powder, and use a roller to crush the bamboo powder into 50 mesh noodles.

[0073] (3) Purchase 400 mesh mineral powder as a filler, the mineral powder is asbestos powder,

[0074] (4) Choose chemical reagents with coupling effect as additives, and the additives a...

Embodiment 3

[0088] The present invention is a production method of aluminum-plastic-wood fiber composite profile, including the following steps:

[0089] Step 1. Material preparation:

[0090] (1) Use high-density polyethylene (HDPE) waste plastic as the main material. The main material can be recycled plastic bottles, plastic tubes, plastic cups and other plastic containers. The materials are all high-density polyethylene (HDPE). The above-mentioned plastic bottles, plastic cylinders, and plastic cups are crushed by a crusher, and then extruded by an extruder into uniformly sized spherical plastic particles (as the main material) for use. The spherical diameter of the plastic particles is 4mm.

[0091] (2) Choose plant fiber as auxiliary material, plant fiber is flax, use a roller to crush the flax into a 60-mesh noodle.

[0092] (3) Purchase 500 mesh mineral powder as filler, the mineral powder is mica powder,

[0093] (4) Use chemical reagents with coupling effect as additives, and the additive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com