Sulfated cellulose ether-acrylamide graft copolymer, preparation method and application thereof

A technology of sulfated cellulose and graft copolymers, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of compound system oil displacement efficiency decline, poor compatibility, "chromatographic separation, etc., and achieve reduction Oil-water interfacial tension, safe use, and the effect of improving oil displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

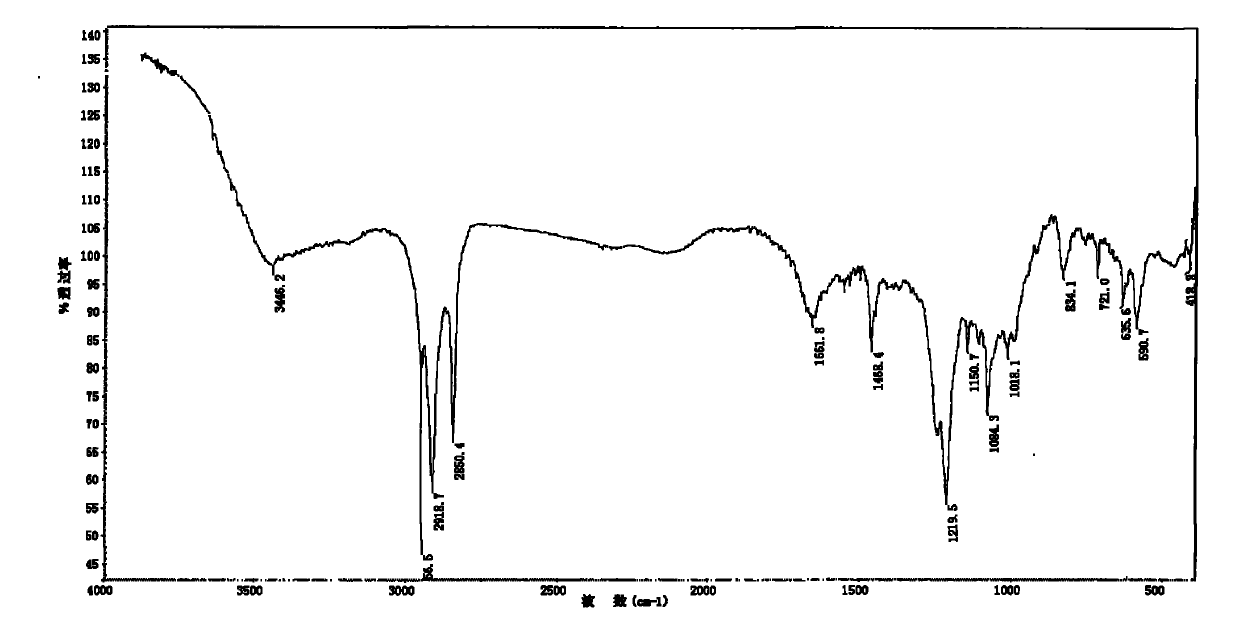

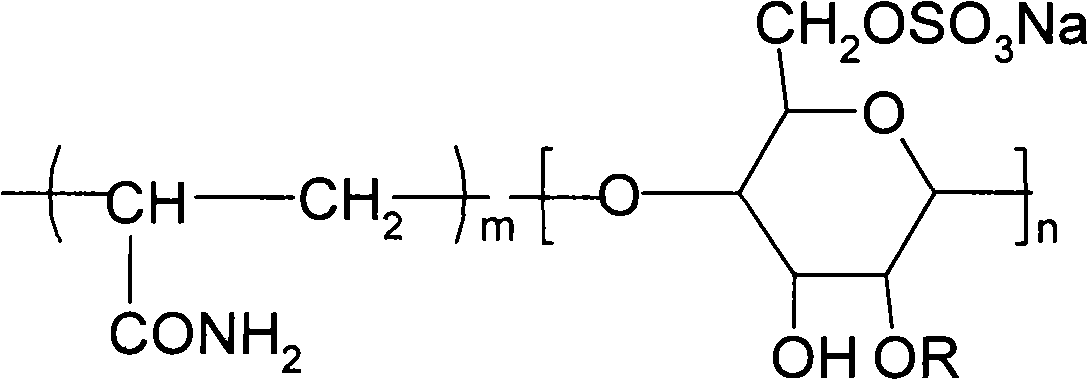

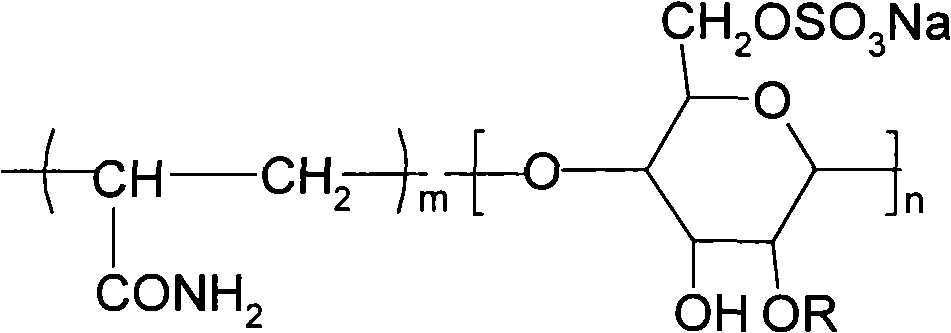

Method used

Image

Examples

Embodiment 1

[0029] In the first step, 3.0 g of sodium cellulose sulfate (substitution degree is 0.39) and 3.8 g of 1-bromododecane (0.015 mol) are dissolved in 150 ml of N, N-dimethylformamide, and added to the Add 0.5 g of sodium hydroxide to a three-necked flask with a stirrer and a thermometer, and stir and react at 90° C. for 5 h. After the reaction was completed, cool to room temperature, add 200ml of ethanol for precipitation, filter and isolate the crude product, recrystallize the product with ethanol, and vacuum dry the purified product at 50°C to obtain sulfated cellulose lauryl ether.

[0030] In the second step, add 4.0 g of sulfated cellulose lauryl ether and 50 ml of distilled water into a three-necked flask equipped with a stirrer, a thermometer, and a nitrogen pipe, feed in nitrogen, and stir for 30 minutes until completely dissolved. At 40°C, add 0.9 ml of ammonium persulfate aqueous solution with a concentration of 1 mg / ml and 1.6 ml of a sodium sulfite aqueous solution w...

Embodiment 2

[0038] The 1st step, cellulose sodium sulfate (substitution degree is 0.39) 3.0g and the 1-bromononane (0.015mol) of 3.1g are dissolved in the N of 150ml, in the N-dimethylformamide, join with Add 0.45 g of sodium hydroxide to a three-necked flask with a stirrer and a thermometer, and stir and react at 90° C. for 6 h. After the reaction was completed, cool to room temperature, add 200ml of ethanol for precipitation, filter and isolate the crude product, recrystallize the product with ethanol, and dry the purified product in vacuum at 50°C to obtain sulfated cellulose nonyl ether.

[0039] In step 2, add 4.0 g of sulfated cellulose nonyl ether and 50 ml of distilled water into a three-necked flask equipped with a stirrer, a thermometer, and a nitrogen pipe, feed in nitrogen, and stir for 30 minutes until completely dissolved. At 30°C, add 0.9 ml of ammonium persulfate aqueous solution with a concentration of 1 mg / ml and 1.6 ml of a sodium sulfite aqueous solution with a concent...

Embodiment 3

[0042] The 1st step, cellulose sodium sulfate (substitution degree is 0.39) 3.0g and 3.4g of 1-bromodecane (0.015mol) are dissolved in the N of 150ml, in the N-dimethylformamide, join with Add 0.5 g of sodium hydroxide to a three-necked flask with a stirrer and a thermometer, and stir and react at 85° C. for 5 h. After the reaction was completed, cool to room temperature, add 200ml of ethanol for precipitation, filter and separate to obtain the crude product, recrystallize the product with ethanol, and vacuum-dry the purified product at 50°C to obtain sulfated cellulose decyl ether.

[0043] In the second step, add 4.0 g of sulfated cellulose decyl ether and 50 ml of distilled water into a three-necked flask equipped with a stirrer, a thermometer, and a nitrogen pipe, feed nitrogen, and stir for 30 minutes until completely dissolved. At 35°C, add 0.9 ml of ammonium persulfate aqueous solution with a concentration of 1 mg / ml and 1.6 ml of a sodium sulfite aqueous solution with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com