Electrode for flow energy storage battery

A flow energy storage battery and electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unsuitable electrode materials for all-vanadium flow batteries, poor mechanical strength, poor electrical conductivity, etc., and achieve high practical value and cost. Inexpensive, improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Put a certain size of carbon felt into the middle of the quartz tube, and then insert it into the tube furnace so that the carbon felt is located in the middle of the tube furnace. Under the protection of a nitrogen atmosphere, the temperature of the tube furnace was raised to 700°C at a heating rate of 10°C / min, and then ammonia gas was introduced to replace the nitrogen gas. Cool to room temperature.

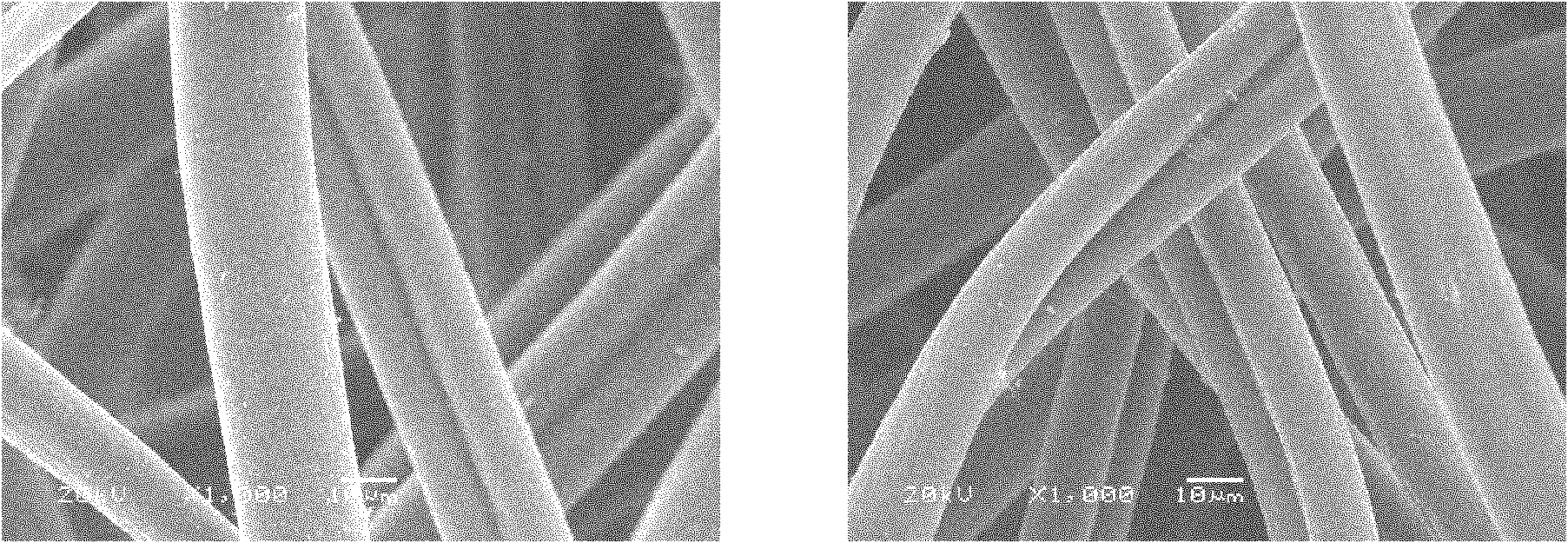

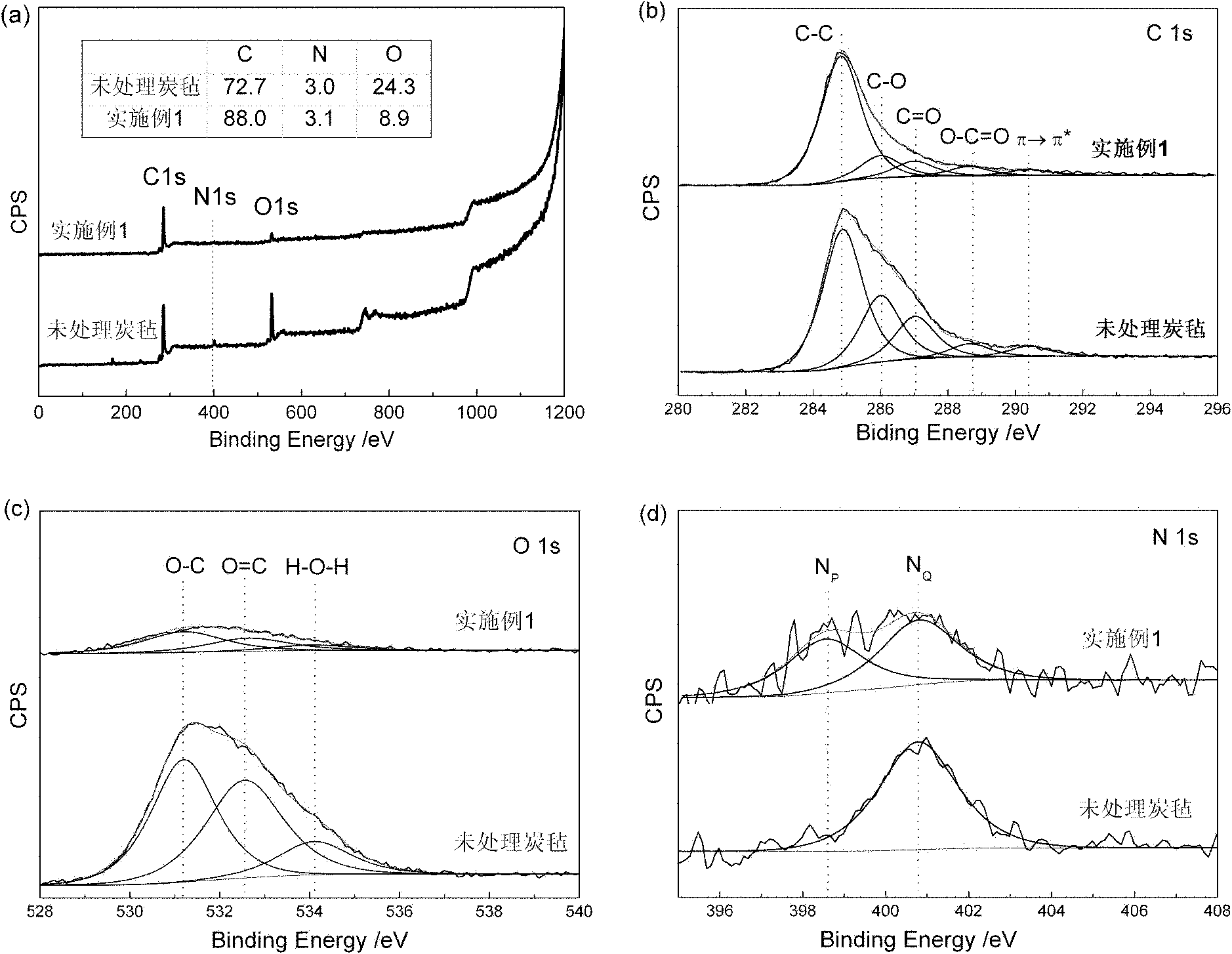

[0037] The morphology of the prepared nitrogen-doped carbon felt is as follows: figure 1 shown. By comparing with the untreated carbon felt, it can be found that there are some small amorphous carbon particles on the surface of the carbon fiber of the untreated carbon felt, and several grooves are distributed; while the surface of the nitrogen-doped carbon felt is cleaner than the untreated carbon felt, and there is no amorphous carbon. Small particles exist, which is caused by the etching effect of ammonia gas, and the grooves are obviously increased, which increases...

Embodiment 2

[0043] Put a certain size of carbon felt into the middle of the quartz tube, and then insert it into the tube furnace so that the carbon felt is located in the middle of the tube furnace. Under the protection of a nitrogen atmosphere, the temperature of the tube furnace was raised to 900°C at a heating rate of 10°C / min, and then ammonia gas was introduced to replace the nitrogen gas. Cool to room temperature.

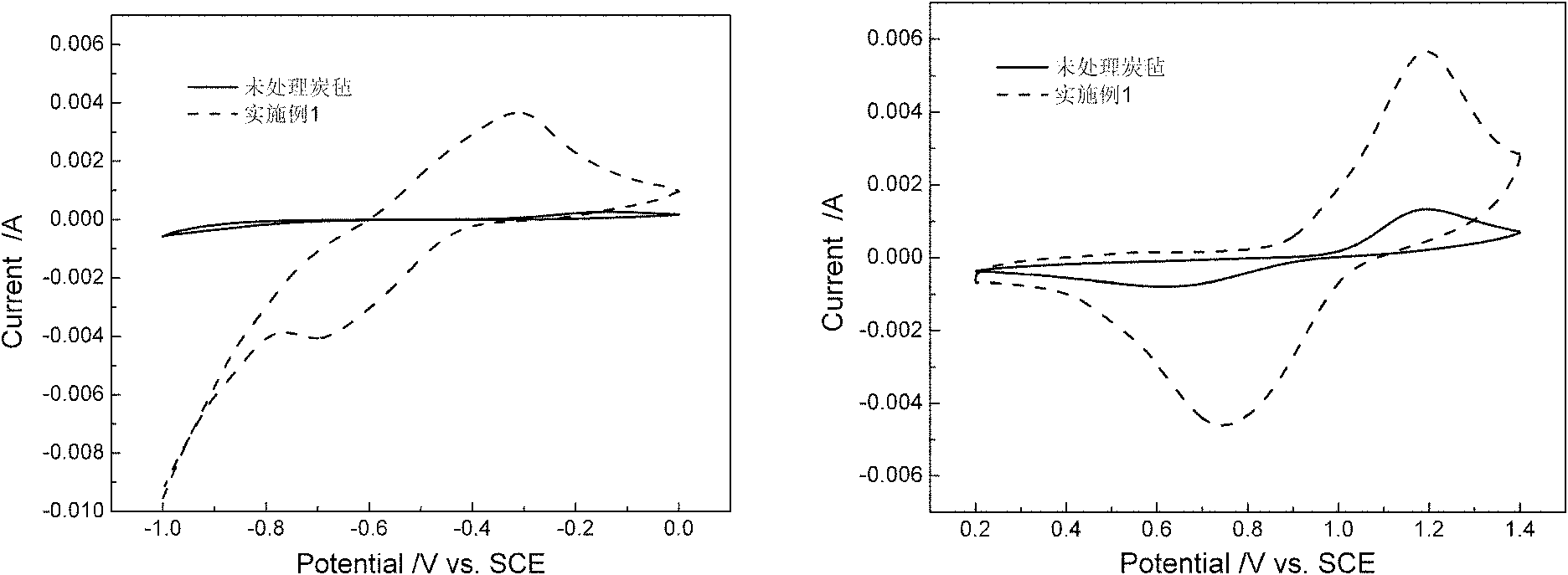

[0044] The cyclic voltammetry curve of the nitrogen-doped carbon felt prepared in this embodiment is as follows Figure 5 As shown, from the electrochemical oxidation and reduction peak positions and peak currents of V(Ⅱ) / V(Ⅲ) and V(Ⅳ) / V(Ⅴ) in the figure, it can be known that V(Ⅱ) / V(Ⅲ) and V(Ⅲ) The electrochemical activity and electrochemical reversibility of (Ⅳ) / V(Ⅴ) couple on nitrogen-doped carbon felt were significantly improved.

Embodiment 3

[0046] Weigh 200mg of melamine and place it in the reactor, and place the carbon felt in the middle of the tube furnace. First raise the temperature of the tube furnace to 800°C at a rate of 10°C / min under a nitrogen atmosphere, and then rapidly heat the reactor to 300°C. At this time, the sublimated melamine will flow through the carbon felt together with nitrogen, and the constant temperature reaction is 0.5 After h, it was lowered to room temperature under a nitrogen atmosphere.

[0047] The cyclic voltammetry curve of the nitrogen-doped carbon felt prepared in this embodiment is as follows Figure 6 As shown, from the electrochemical oxidation and reduction peak positions and peak currents of V(Ⅱ) / V(Ⅲ) and V(Ⅳ) / V(Ⅴ) in the figure, it can be known that V(Ⅱ) / V(Ⅲ) and V(Ⅲ) The electrochemical activity and electrochemical reversibility of (Ⅳ) / V(Ⅴ) couple on nitrogen-doped carbon felt were significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com