Preparation method for polystyrene-resin-loaded nano zero valent iron, and application of polystyrene-resin-loaded nano zero-valent iron to oily wastewater

A polystyrene resin, nano-zero valent iron technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, reduced water/sewage treatment, etc. small space, good dispersibility and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

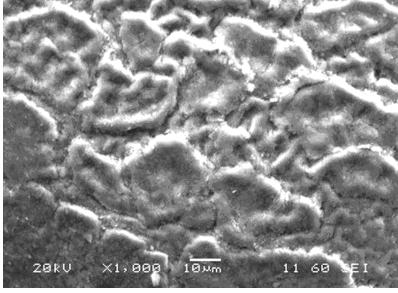

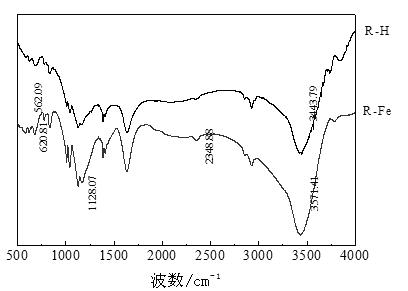

[0020] Preparation of polystyrene resin-loaded nano-zero-valent iron materials:

[0021] (1) Treat the resin with 4mol / L hydrochloric acid for 1 hour to exchange the sodium ions on the surface of the resin for H + , and rinsed with distilled water.

[0022] (2) FeSO 4 ·7H 2 O and the treated resin are added according to the mass ratio of 1:5, that is, 5g:25g is added to 100ml of distilled water, and then 1g of polyvinylpyrrolidone is added, put into a magnetic stirrer with water, and exchanged for 1h under magnetic stirring, Guaranteed all Fe 2+ Exchange to the surface of the cation exchange resin, and then wash the exchanged resin with distilled water to remove the unexchanged Fe on the resin surface 2+ .

[0023] (3) Prepare 0.2mol / L NaBH with distilled water 4 solution, transfer 20g of the resin in (2) to a beaker filled with 100ml of distilled water, and slowly add 100ml of NaBH under the action of magnetic stirring 4 solution, the resin quickly changed from light y...

Embodiment 2

[0027] 1 Determination of oil concentration by ultraviolet method

[0028] Preparation of solution

[0029] (1) Standard oil: use 30-60°C petroleum ether to extract oil from the collected steel rolling oily wastewater samples, dehydrate and filter through anhydrous sodium sulfate, put the filtrate on a (65±5°C) water bath to evaporate petroleum ether, and then Drain the remaining petroleum ether in a thermostat (65±5°C) to obtain the standard oil.

[0030] (2) Standard oil stock solution: Weigh standard oil (0.100±0.001) g and dissolve it in petroleum ether, transfer it into a 100ml volumetric flask, dilute to the mark line, and store in the refrigerator. 1ml of this solution contains 1.00mg of oil.

[0031] (3) Standard oil solution: Before use, take 10ml of standard oil stock solution and transfer it into a 100ml volumetric flask, then dilute to the marked line. 1ml of this solution contains 0.10mg of oil.

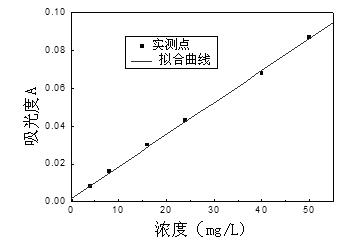

[0032] Drawing of standard curve

[0033] (1) First scan to the...

Embodiment 3

[0053] The calculation method of oil concentration measurement method, turbidity measurement method, oil removal rate and turbidity removal rate is the same as shown in embodiment 2 in this example.

[0054] Prepare oily wastewater with an initial concentration of 146mg / L and a turbidity of 203NTU. Use a 150ml Erlenmeyer flask as a reactor, add 2g of polystyrene resin loaded with nanometer zero-valent iron to the bottle, and then add 100ml of oily wastewater at a temperature of 40 °C, the reaction time is 30 min on a constant temperature SHA-B oscillator at a rotation speed of 180 rpm. After the reaction, it was left to stand for 1 hour, and water samples were taken for measurement according to the oil concentration and turbidity in Example 2, and the oil removal rate and turbidity removal rate were 93.87% and 77.34% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com