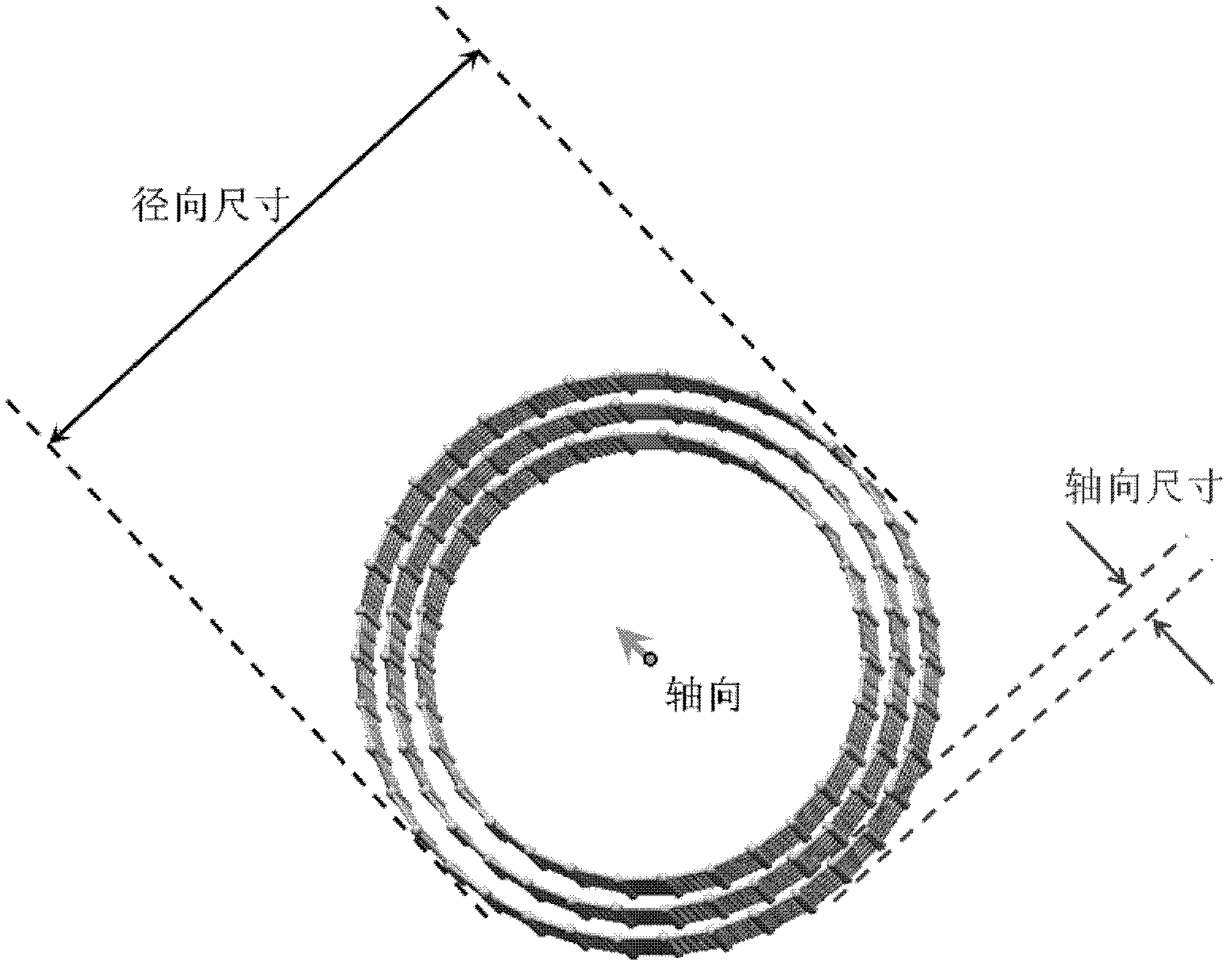

Carbon nanometer ring and preparation method thereof

A technology of carbon nano-rings and carbon rings, applied in the direction of nano-carbon, nano-technology, etc., can solve the problems of difficult stable existence, large damage of carbon tube structure, difficulty in obtaining ultra-short carbon nano-tubes, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

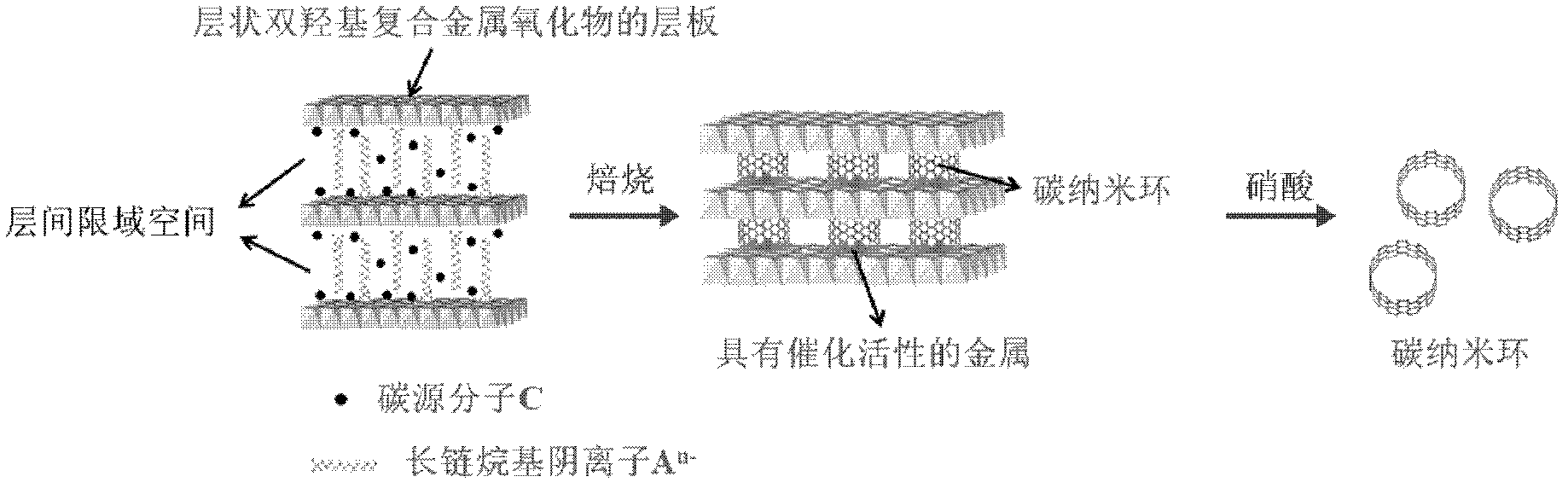

Method used

Image

Examples

Embodiment 1

[0049] 0.075mol cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 0.025mol aluminum nitrate (Al(NO 3 ) 3 9H 2 O), 0.025mol sodium dodecyl sulfate (dodecyl sulfate is abbreviated as DS - ) and 0.25mol methyl methacrylate (MMA) were dissolved in 300mL decarbonated deionized water, stirred and mixed for 20 minutes under nitrogen protection, to obtain a pink, clear and transparent mixed salt solution;

[0050] Under nitrogen protection and constant stirring, 80 mL of NaOH solution with a concentration of 2.5 mol / L prepared with decarbonated deionized water was added dropwise to the above mixed salt solution to obtain a mixed solution;

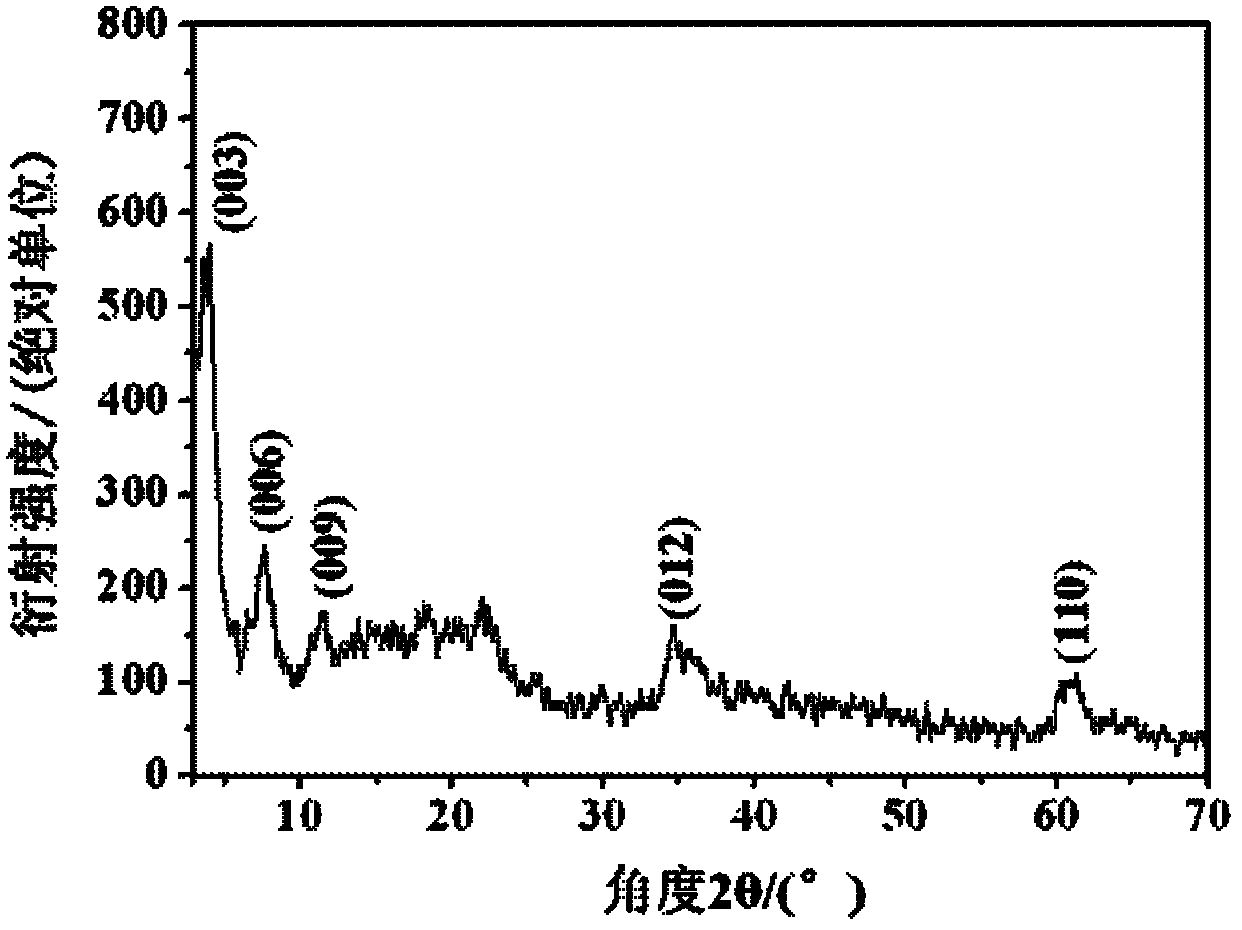

[0051] Under a nitrogen atmosphere, the above mixed solution was reacted at 80°C for 8 hours, the obtained suspension was filtered, the reaction product was washed with deionized water until the pH of the filtrate was 7.2, and then the filter cake was dried at 50°C for 12 hours, The layered bishydroxy compound metal oxide with intercalation structure was...

Embodiment 2

[0063] 0.025mol cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 0.025mol magnesium nitrate (Mg(NO 3 ) 2 ·6H 2 O), 0.025mol aluminum nitrate (Al(NO 3 ) 3 9H 2 O), 0.025mol sodium dodecylsulfonate (dodecylsulfonate is abbreviated as DSO - ) and 0.75mol n-pentane (P) were dissolved in 150mL de-carbonated deionized water, stirred and mixed under nitrogen protection for 20 minutes to obtain a pink, clear and transparent mixed salt solution;

[0064] Under nitrogen protection and constant stirring, add dropwise 30 mL of NaOH solution with a concentration of 5 mol / L prepared with decarbonated deionized water into the above mixed salt solution to obtain a mixed solution;

[0065]Under a nitrogen atmosphere, the above mixed solution was reacted at 70°C for 10 hours, the resulting suspension was filtered, the reaction product was washed with deionized water until the pH of the filtrate was 7.5, and then the filter cake was dried at 60°C for 8 hours, The layered bishydroxy compound metal ...

Embodiment 3

[0076] 0.1mol zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O), 0.01mol iron nitrate (Fe(NO 3 ) 3 9H 2 O), 0.015mol aluminum nitrate (Al(NO 3 ) 3 .9H 2 O), 0.025mol sodium dodecylbenzenesulfonate (dodecylbenzenesulfonate is abbreviated as DBS - ) and 0.5mol toluene (MB) were dissolved in 625mL decarbonated deionized water, stirred and mixed for 20 minutes under nitrogen protection, to obtain a yellow, clear and transparent mixed salt solution;

[0077] Under nitrogen protection and constant stirring, add 100 mL of NaOH solution with a concentration of 2.5 mol / L prepared with decarbonated deionized water to the above mixed salt solution dropwise to obtain a mixed solution;

[0078] Under a nitrogen atmosphere, the above mixed solution was reacted at 60°C for 6 hours, the resulting suspension was filtered, the reaction product was washed with deionized water until the pH of the filtrate was 7.0, and the filter cake was dried at 55°C for 6 hours to obtain The layered double hydroxyl c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com