Preparation method for lithium battery anode material LiNi0.5Mn1.5O4

A lithium-ion battery, cathode material technology, applied in the direction of manganate/permanganate, etc., can solve the problems of unstable sol state, affecting electrochemical performance, precipitation, etc., achieving good crystallization performance, avoiding precipitation, particle size small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

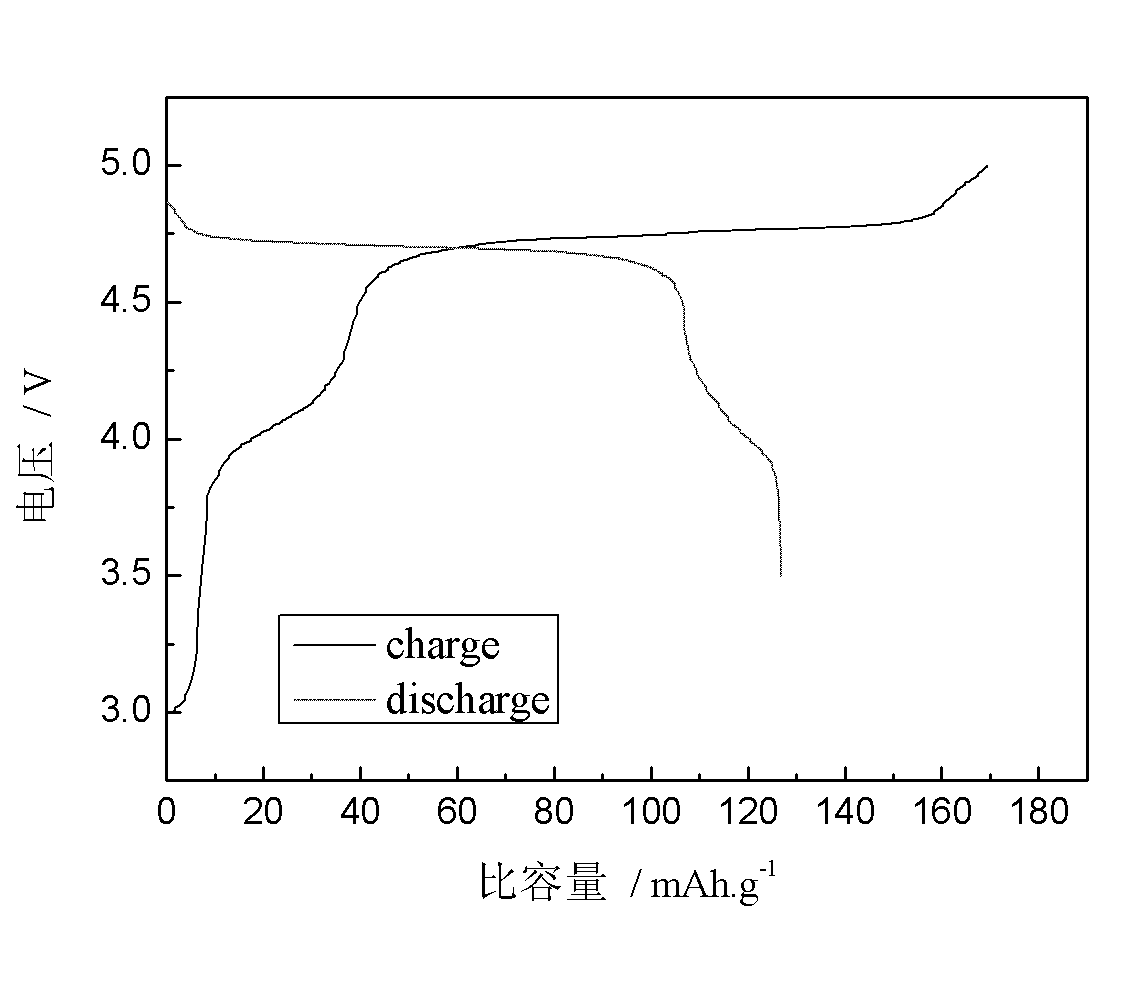

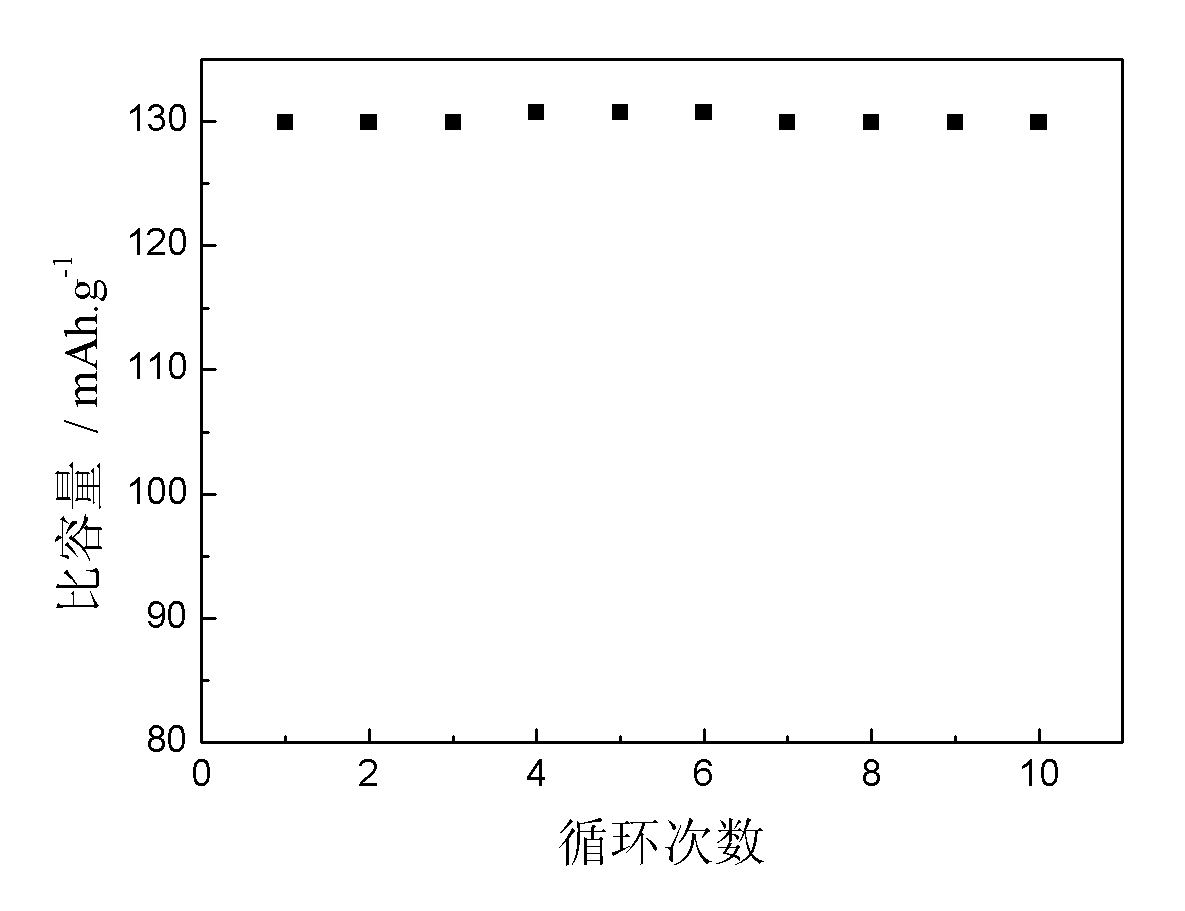

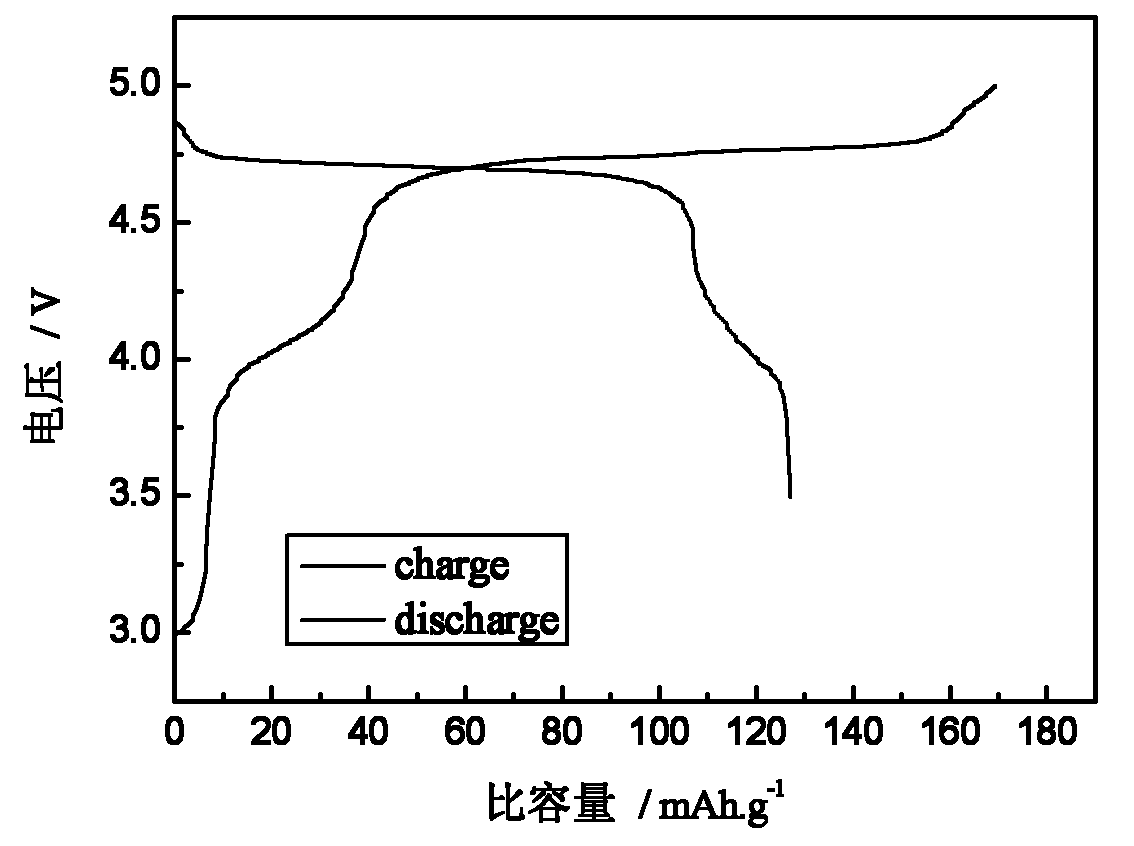

Examples

Embodiment 1

[0020] A kind of lithium-ion battery cathode material LiNi 0.5 mn 1.5 o 4 The preparation method comprises following preparation steps:

[0021] A. Prepare the solution: first weigh 0.0105mol of LiCH 3 COO·2H 2 O, 0.005mol of Ni(CH 3 COO) 2 4H 2 O, 0.015mol of Mn(CH 3 COO) 2 4H 2 O, join in 250ml deionized water and constantly stir to make it mix evenly, be mixed with mixed solution I; Then take the citric acid of 0.0305mol, add deionized water and be mixed with 100ml chelating agent under stirring; Finally chelating agent is dripped slowly Put into the mixed solution I in the constant stirring, utilize ammonia water to adjust the solution pH value to be 7, configure and obtain the mixed solution II; The weighing amount of lithium acetate dihydrate, nickel acetate tetrahydrate, manganese acetate tetrahydrate is according to , The ratio of the amount of Mn is 1.05:0.5:1.5.

[0022] B. Add cetyltrimethylammonium bromide (CTAB) dropwise: take 0.0305mol of CTAB and add ...

Embodiment 2

[0028] A kind of lithium-ion battery cathode material LiNi 0.5 mn 1.5 o 4 The preparation method comprises following preparation steps:

[0029] A. Prepare the solution: first weigh 0.0105mol of LiCH 3 COO·2H 2 O, 0.005mol of Ni(CH 3 COO) 2 4H 2 O, 0.015mol of Mn(CH 3 COO) 2 4H 2 O, join in 250ml deionized water and constantly stir to make it mix evenly, be mixed with mixed solution I; Then take the citric acid of 0.0305mol, add deionized water and be mixed with 100ml chelating agent under stirring; Finally chelating agent is dripped slowly Into the mixed solution I in the constant stirring, utilize ammonia water to adjust the pH value of the solution to be 6~8, configure to obtain the mixed solution II; The ratio of the amount of substances of Ni, Mn is 1.05:0.5:1.5.

[0030] B. Add cetyltrimethylammonium bromide (CTAB) dropwise: take 0.0305mol of CTAB and add it to deionized water to prepare 250ml solution III. After stirring the mixed solution II obtained in step...

Embodiment 3

[0036] A kind of lithium-ion battery cathode material LiNi 0.5 mn 1.5 o 4 The preparation method comprises following preparation steps:

[0037] A. Prepare the solution: first weigh 0.0105mol of LiCH 3 COO·2H 2 O, 0.005mol of Ni(CH 3 COO) 2 4H 2 O, 0.015mol of Mn(CH 3 COO) 2 4H 2 O, join in 250ml deionized water and constantly stir to make it mix evenly, be mixed with mixed solution I; Then take the citric acid of 0.0305mol, add deionized water and be mixed with 100ml chelating agent under stirring; Finally chelating agent is dripped slowly Put into the mixed solution I in the constant stirring, utilize ammonia water to adjust the solution pH value to be 8, configure and obtain mixed solution II; , The ratio of the amount of Mn is 1.05:0.5:1.5.

[0038] B. Add cetyltrimethylammonium bromide (CTAB) dropwise: take 0.0305mol of CTAB and add it to deionized water to prepare 250ml solution III. After the mixed solution II obtained in step A is stirred rapidly for 5 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com