Preparation method of poly(p-phenylene) nanoparticle composite ZnO-based thermoelectric material system

A nanoparticle and polyparaphenylene technology, which is applied in the field of new energy material preparation, can solve the problems of scarcity of resources, reduce material thermal conductivity, increase phonon interface scattering, etc. Increase the effect of interface scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

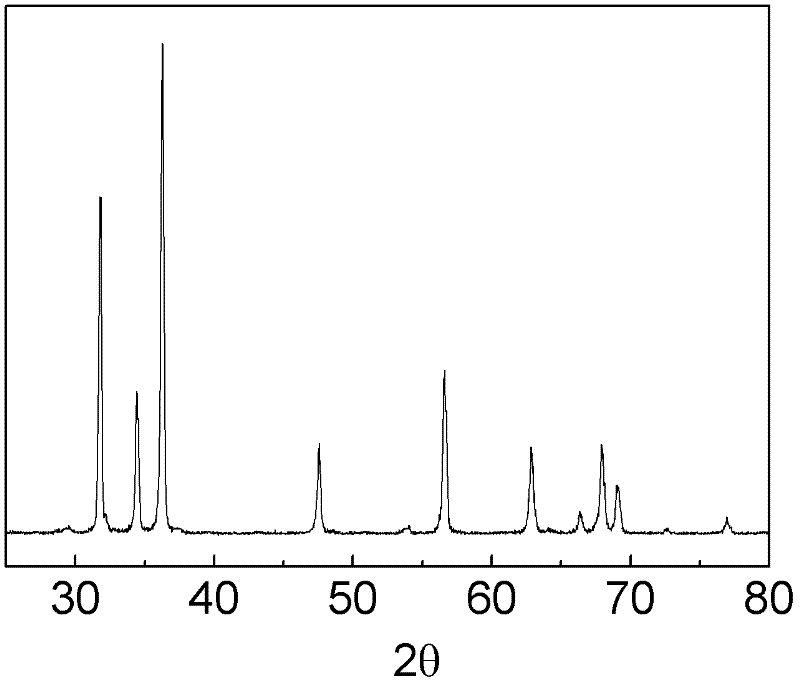

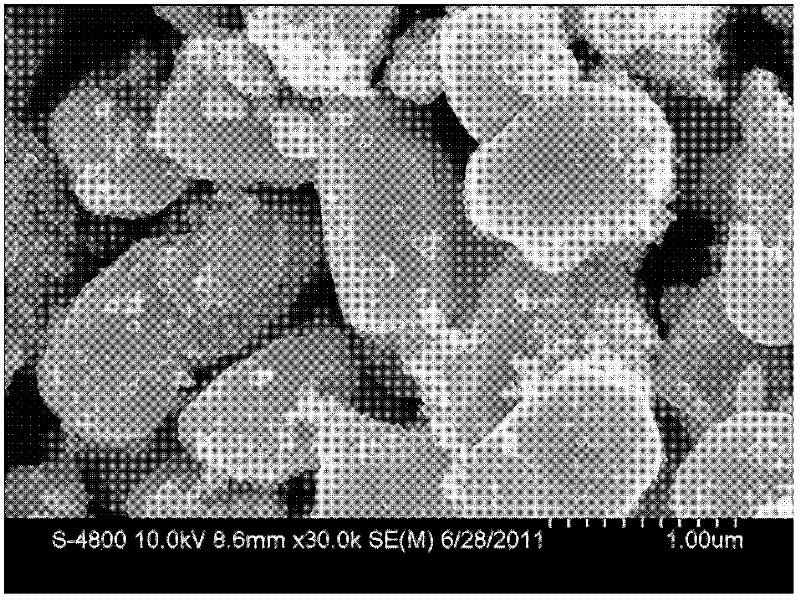

[0022] Example 1. Preparation of poly-p-phenylene nanoparticle composite ZnO-based thermoelectric material

[0023] First, put poly-p-phenylene into 85% sulfuric acid, stir at 30°C for 8 minutes, filter, wash and then dry. The obtained sample is ball-milled on a high-energy ball mill for 3 hours at a speed of 210r / min; 13.23g of zinc acetate Dissolve 3000ml of diethylene glycol, add 120ml of water, stir at 165°C for 10 minutes, wait for a white precipitate to stand for 2 hours to obtain ZnO sol, and weigh 0.0057g of the treated poly-p-phenylene The particles were added to ZnO sol and stirred, then dispersed under ultrasonic conditions for 30 minutes, heated to 165°C for 1 hour, filtered, washed with absolute ethanol and deionized water several times, and finally dried at 100°C to obtain nanopowder materials. The bulk poly-p-phenylene nanoparticle composite ZnO-based thermoelectric material was prepared by spark plasma sintering of the powder material. The sintering conditions ...

Embodiment 2

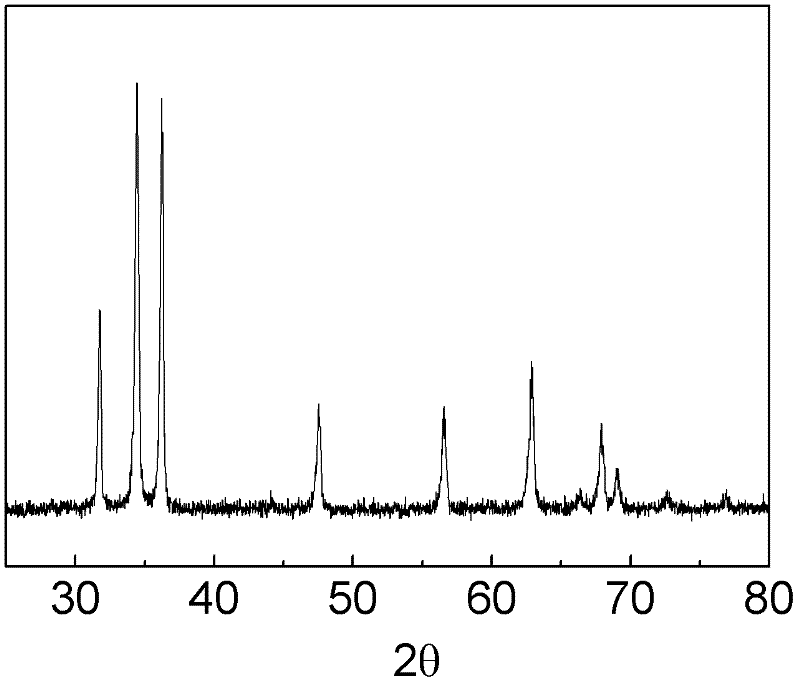

[0024] Example 2. Preparation of poly-p-phenylene nanoparticles composite Zn0.925Co0.075O-based thermoelectric material

[0025] Poly-p-phenylene was stirred in 85% sulfuric acid at 30°C for 10 minutes, filtered, washed and then dried. The obtained sample was ball-milled on a high-energy ball mill for 3 hours at a speed of 180r / min; 13.23g of zinc acetate and 1.125g of cobalt acetate were dissolved Add 3000ml of diethylene glycol, add 120ml of water, stir at 160°C for 10 minutes, wait for 2 hours after the white precipitate appears, and make ZnO sol, weigh 0.0019g of processed poly-p-phenylene particles Add ZnO sol and stir, then disperse under ultrasonic conditions for 30 minutes, heat up to 160°C for 1 hour, filter, wash with absolute ethanol and deionized water several times, and finally dry at 100°C to obtain nanopowder materials. The bulk poly-p-phenylene nanoparticle composite Zn0.925Co0.075O-based thermoelectric material was prepared by spark plasma sintering of the pow...

Embodiment 3

[0026] Example 3. Preparation of poly-p-phenylene nanoparticles composite Zn0.95Ag 0.05O-based thermoelectric material

[0027] Poly-p-phenylene was put into 85% sulfuric acid, stirred at 30°C for 8 minutes, filtered, washed and then dried. The obtained sample was ball-milled on a high-energy ball mill for 4 hours at a speed of 210r / min; 13.2g of zinc acetate and 0.52 Dissolve 1 g of silver acetate into 3000ml of diethylene glycol, add 120ml of water, stir at 170°C for 10 minutes, and let it stand for 2 hours after the white precipitate appears to obtain ZnO sol. Weigh 0.0040g of the processed poly Add ZnO sol to the phenylene particles and stir, then disperse under ultrasonic conditions for 30 minutes, heat up to 170 ° C for 1 hour, filter, wash with absolute ethanol and deionized water for several times, and finally dry at 100 ° C to obtain nano powder material. The bulk poly-p-phenylene nanoparticle composite Zn0.925Co0.075O-based thermoelectric material was obtained by sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com