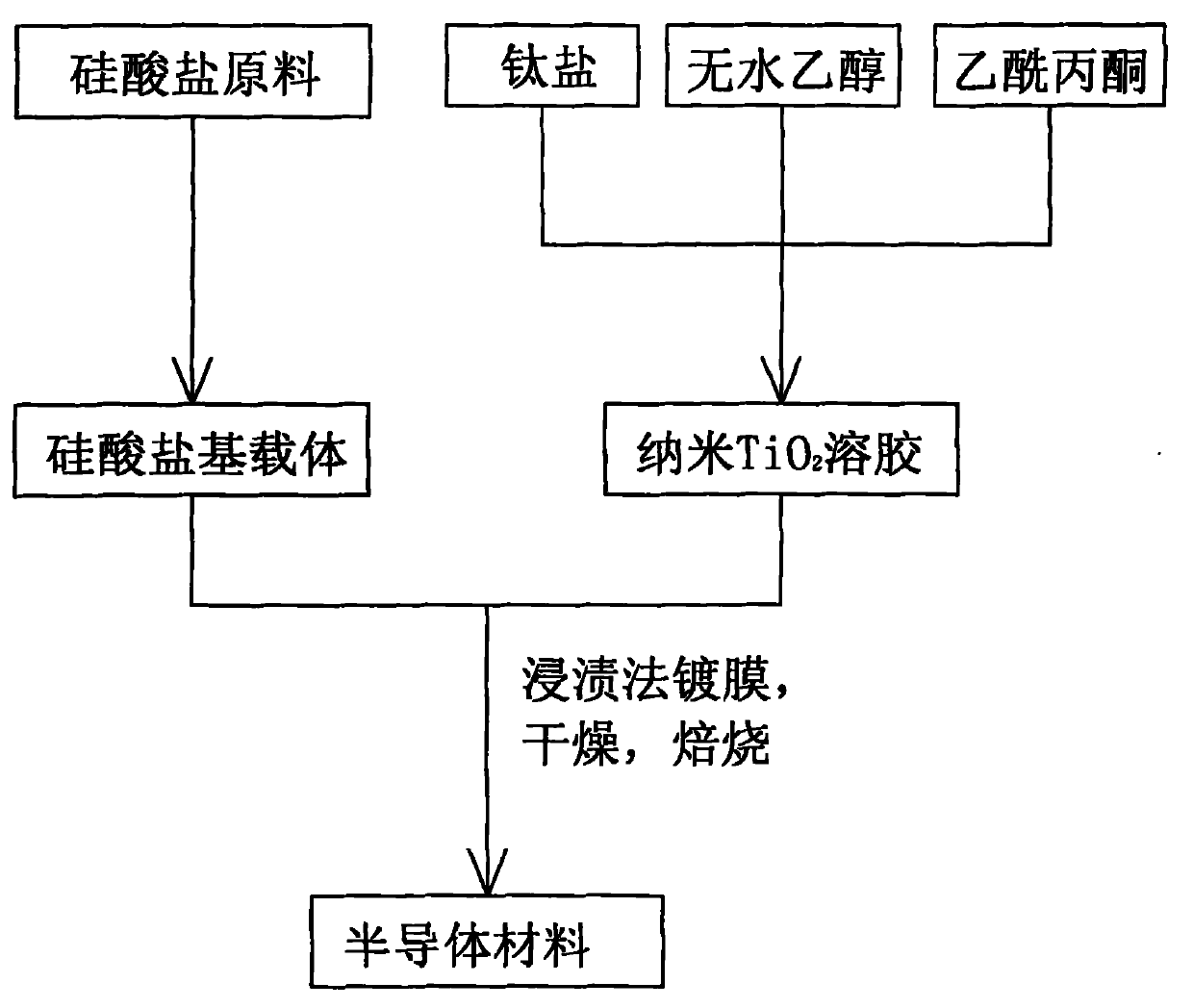

Preparation method of nano semiconductor material loaded on silicate substrate

A nano-semiconductor and silicate technology, which is applied in the field of preparation of nano-semiconductor materials, can solve the problems that the effect of purifying air cannot be fully exerted, and achieve the effects of easy large-scale production, easy availability of raw materials, and good photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Add 5ml of sodium carbonate solution with a concentration of 15% to 100g of diatomite with a particle size of 20-50μm, mix well, and then transfer to a reaction kettle for roasting and puffing. The roasting temperature is 500°C, and the pressure in the kettle is 1MPa, the roasting time is 10min. After the calcination, the calcination product is taken out and cooled to room temperature, ground and sieved, and the sieved particle size ranges from 0.5 to 30 μm to obtain a powdery diatomite-based carrier.

[0034] (2) Take 30g of absolute ethanol and 20g of butyl titanate in a container, stir and mix together to form a mixed solution, and add 2g of acetylacetone solution and 10g of 20% ethanol solution to the mixed solution in turn while stirring , After adding all the acetylacetone solution and ethanol aqueous solution, continue to stir for 4 hours to obtain a stable, uniform and transparent light yellow sol, which is left to stand for 12 hours before use.

[0035] (3...

Embodiment 2

[0037] (1) Add 5ml of potassium hydroxide solution with a concentration of 20% to 100g of zeolite with a particle size of 20-50μm, mix well, then transfer to a reaction kettle for roasting and puffing, the roasting temperature is 650°C, and the pressure inside the kettle is 0.8 MPa, the roasting time is 5min. After the calcination, the calcination is taken out and cooled to room temperature, ground and sieved, and the sieved particle size ranges from 0.5 to 30 μm to obtain a powdery zeolite-based carrier.

[0038] (2) Take 80g of absolute ethanol and 20g of titanyl sulfate in a container, stir and mix them together with a stirrer to form a mixed solution, and then add 6g of glacial acetic acid solution and 24g of 20% concentration of acetic acid to the mixed solution while stirring. After all the ethanol solution, acetylacetone solution and ethanol water solution were added, the stirring was continued for 6 hours to obtain a stable, uniform and transparent light yellow sol, wh...

Embodiment 3

[0041] (1) Add 5ml of 20% sodium bicarbonate solution to the silicate mixture containing 80g of diatomite with a particle size of 20-50μm and 70g of vermiculite with a particle size of 20-50μm, mix well, and then transfer Carry out roasting and puffing in the reaction kettle, the roasting temperature is 850° C., the pressure inside the kettle is 1.3 MPa, and the roasting time is 3 minutes. After the calcination, the calcination is taken out and cooled to room temperature, ground and sieved, and the sieved particle size ranges from 0.5 to 30 μm to obtain a powdered silicate carrier.

[0042] (2) Take 40g of absolute ethanol and 20g of butyl titanate in a container, stir and mix them together with a stirrer to form a mixed solution, and then add 4g of acetylacetone solution, 20g of 20% concentration to the mixed solution while stirring After all the ethanol solution, acetylacetone solution and ethanol aqueous solution were added, the stirring was continued for 8 hours to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com