Process for producing battery-grade lithium carbonate through processing carbonate type lithium concentrate by deep carbonation method

A technology of carbonate type and lithium concentrate, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problems of high energy consumption, lithium slag, large amount of slag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

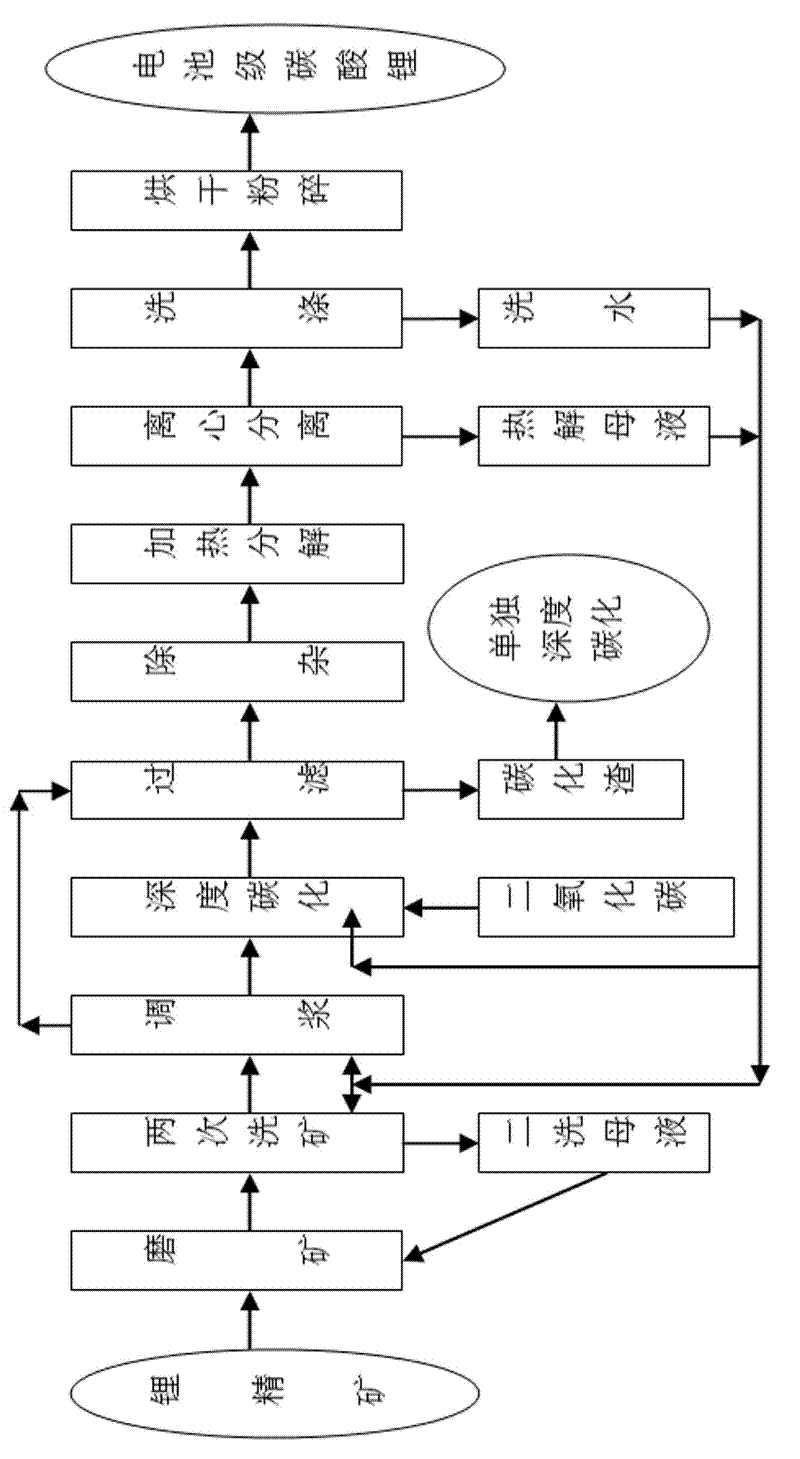

Method used

Image

Examples

Embodiment 1

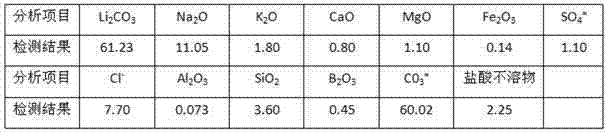

[0052] Table 3 Lithium concentrate composition analysis table

[0053]

[0054] Add lithium concentrate with a grade of 61.23% and industrial water into a ball mill for grinding. The liquid-solid ratio of the lithium concentrate slurry is 1.5:1. After grinding, the fineness of the concentrate reaches 91.2% under a 200-mesh sieve to obtain lithium concentrate slurry;

[0055] 2. Primary ore washing and secondary ore washing Put the ground lithium concentrate slurry into the enamel reaction kettle, stir while heating up, after heating up to 90°C, stir for 40 minutes and filter with a belt filter to obtain a primary Wash lithium concentrate and a wash mother liquor;

[0056] Put the first-time washing lithium concentrate into the enamel reaction kettle, adjust the liquid-solid ratio to 2:1 with industrial water, stir in the enamel reaction kettle for 40 minutes at 92°C, and then filter it with a belt filter to obtain the second washing Lithium concentrate and secondary washi...

Embodiment 2

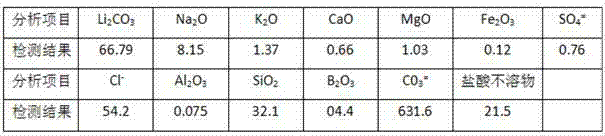

[0073] Table 5 Lithium concentrate composition analysis table

[0074]

[0075] The lithium concentrate with a grade of 66.79% and the mother liquor of the second washing are added to a ball mill for grinding. The liquid-solid ratio of the lithium concentrate slurry is 1.3:1. mineral slurry;

[0076]2. Primary ore washing and secondary ore washing Put the ground lithium concentrate slurry into the enamel reaction kettle, stir and react for 40 minutes at 95°C, and then filter it with a belt filter to obtain the first-time washing lithium concentrate and a wash mother liquor;

[0077] Put the first-time washed lithium concentrate into the enamel reaction kettle, adjust the liquid-solid ratio to 2:1 with the pyrolysis mother liquor, stir in the enamel reaction kettle for 40 minutes at 90°C, and then filter it with a belt filter to obtain the second Wash the lithium concentrate and the second washing mother liquor; the weight percentage content of isolated lithium carbonate r...

Embodiment 3

[0094] 2. Primary ore washing and secondary ore washing Put the ground lithium concentrate slurry into the enamel reaction kettle, stir and react for 40 minutes at a temperature of 93°C, and then filter it with a belt filter to obtain the primary washing lithium concentrate and a wash mother liquor;

[0095] Put the first-time washed lithium concentrate into the enamel reaction kettle, adjust the liquid-solid ratio to 2:1 with the pyrolysis mother liquor, stir in the enamel reaction kettle for 40 minutes at 95°C, and then filter it with a belt filter to obtain the second Washing the lithium concentrate and the second washing mother liquor; the weight percentage content of isolated lithium carbonate reaches 86.8%;

[0096] 3. Sizing The liquid-solid ratio of the slurry is 3:1 to obtain the lithium concentrate slurry; the rest are the same as in Example 2;

[0097] 4. Deep carbonization Add the lithium concentrate slurry to the carbonization tower in excess of 3% of the calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com