Nano-grade porous aerogel and preparation method thereof

A nanoporous carbon and aerogel technology, which is applied in the preparation/purification of carbon, nanotechnology and other directions, can solve the problems that restrict the industrial production of carbon aerogel and its comprehensive and wide application, the unsafe preparation process, and the lengthy preparation cycle. problems, to achieve the effect of good market prospects, low equipment requirements, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

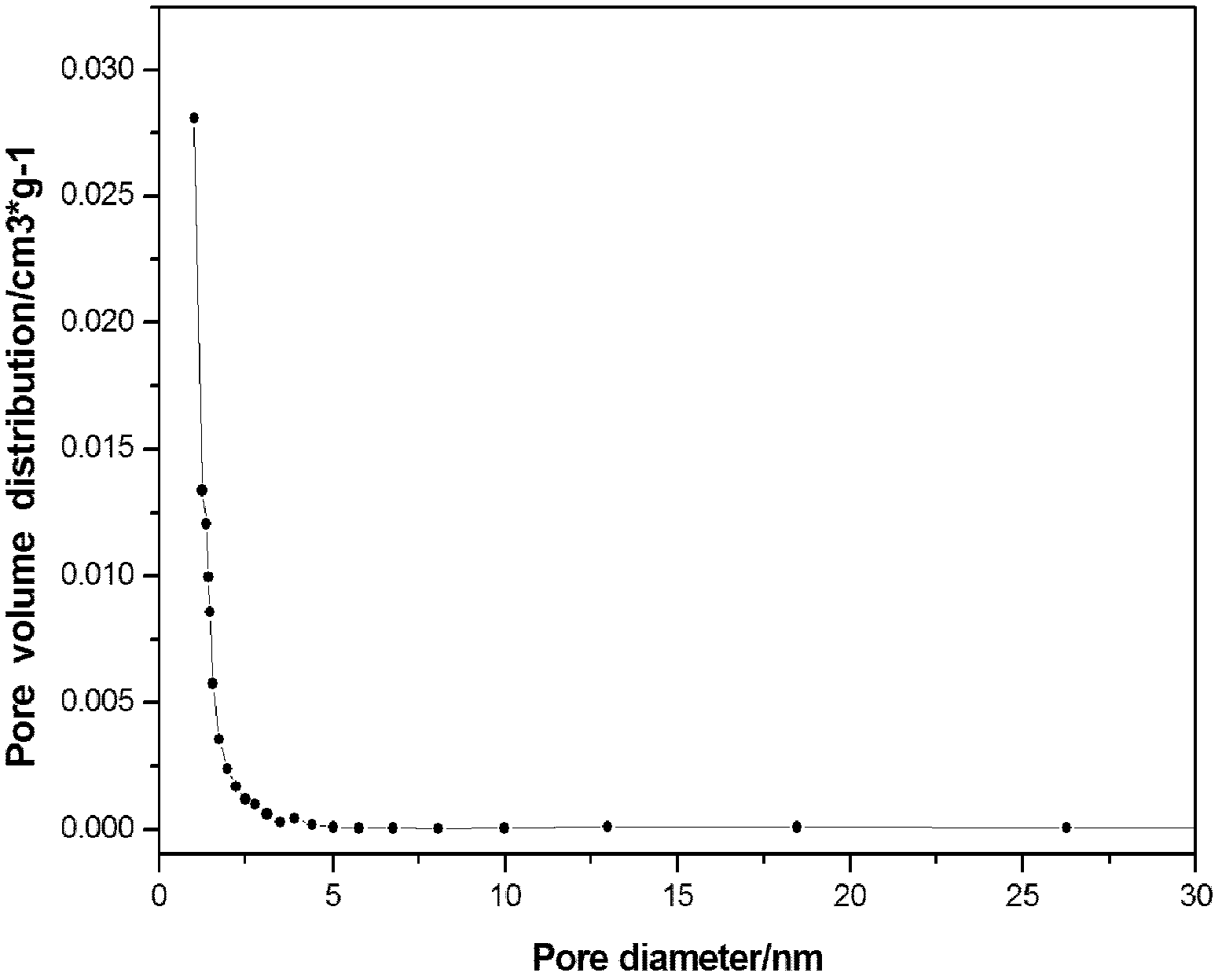

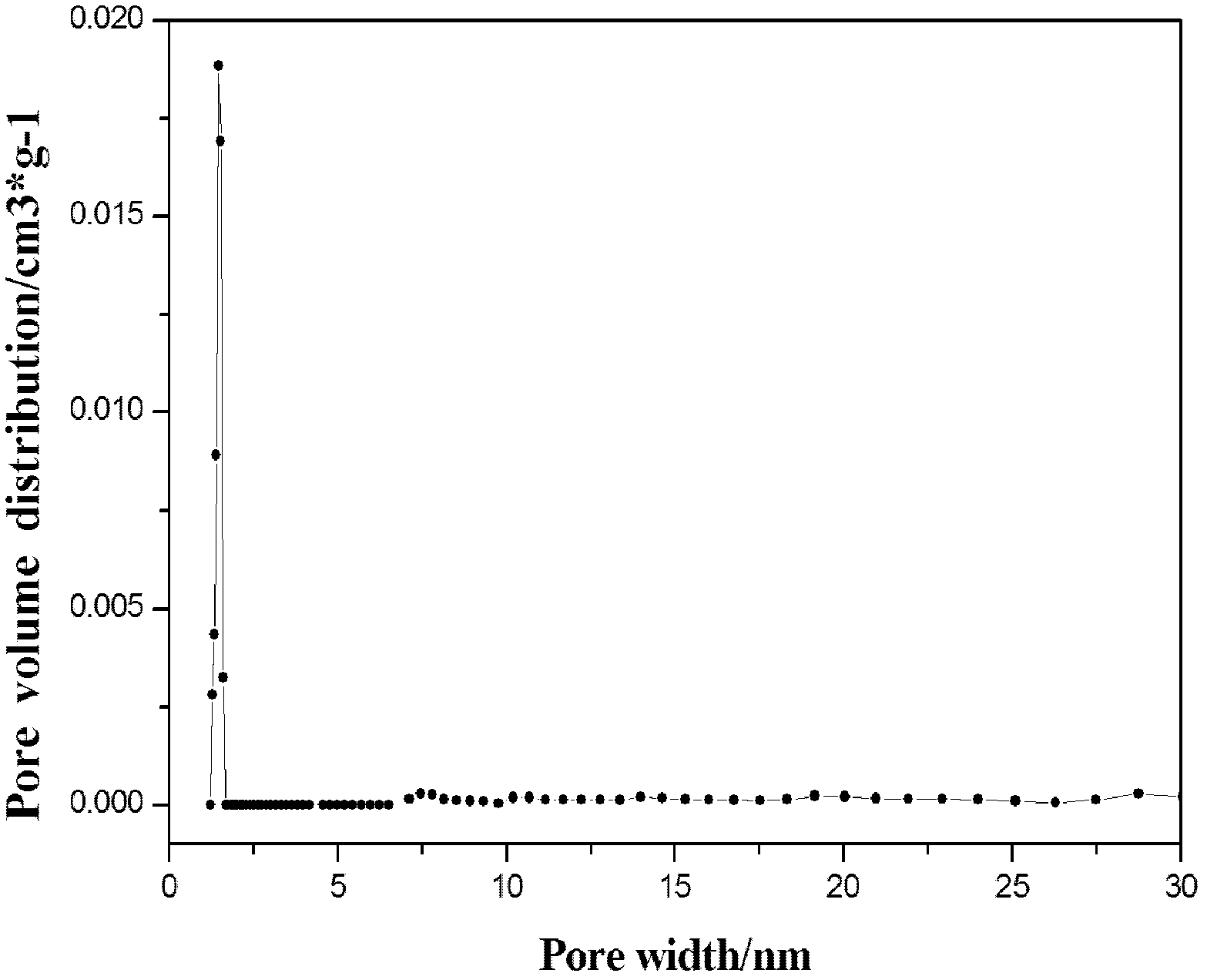

Image

Examples

Embodiment 1

[0023] 1) Preparation of organic wet gel: the reactant resorcinol and formaldehyde are mixed in a molar ratio of 1 / 2, then deionized water is added as a solvent to form a reaction solution with a mass percentage of 30%. A sodium carbonate solution with a concentration of 0.05mol / L is used as a catalyst. After stirring evenly, seal it, put it in an oven, and treat it at 30°C for 1 day, at 50°C for 1 day, and at 90°C for 3 days, and finally obtain Resorcinol-formaldehyde wet gel;

[0024] 2) Solvent replacement: Soak the resorcinol-formaldehyde wet gel prepared in step 1) in acetone for solvent replacement, and replace the acetone every 24 hours for 3 times. Obtain resorcinol-formaldehyde organic airgel;

[0025] 3) Atmospheric pressure drying: drying at normal temperature and pressure, that is, at a temperature of 20-30° C., at a standard atmospheric pressure, and allowing the acetone to evaporate naturally, to obtain a dried resorcinol-formaldehyde organic airgel;

[0026] 4...

Embodiment 2

[0029] 1) Preparation of organic wet gel: the reactant resorcinol and formaldehyde are mixed in a molar ratio of 1 / 2, and then deionized water is added as a solvent to form a reaction solution with a mass percentage of 32%. A sodium carbonate solution with a concentration of 0.05mol / L is used as a catalyst. After stirring evenly, seal it, put it in an oven, and treat it at 30°C for 1 day, at 50°C for 1 day, and at 90°C for 3 days, and finally obtain Resorcinol-formaldehyde wet gel;

[0030] 2) Solvent replacement: Soak the resorcinol-formaldehyde wet gel prepared in step 1) in acetone for solvent replacement. During this period, replace the acetone every 24 hours for 4 times. After the acetone volatilizes completely, the Obtain resorcinol-formaldehyde organic airgel;

[0031] 3) Atmospheric pressure drying: drying at normal temperature and pressure, that is, at a temperature of 20-30° C., at a standard atmospheric pressure, and allowing the acetone to evaporate naturally, to ...

Embodiment 3

[0035] 1) Preparation of organic wet gel: the reactant resorcinol and formaldehyde are mixed in a molar ratio of 1 / 2, and then deionized water is added as a solvent to form a reaction solution with a mass percentage of 33%. A sodium carbonate solution with a concentration of 0.05mol / L is used as a catalyst. After stirring evenly, seal it, put it in an oven, and treat it at 30°C for 1 day, at 50°C for 1 day, and at 90°C for 3 days, and finally obtain Resorcinol-formaldehyde wet gel;

[0036] 2) Solvent replacement: Soak the resorcinol-formaldehyde wet gel prepared in step 1) in acetone for solvent replacement. During this period, replace the acetone every 24 hours for 5 times. After the acetone volatilizes completely, the Obtain resorcinol-formaldehyde organic airgel;

[0037] 3) Atmospheric pressure drying: drying at normal temperature and pressure, that is, at a temperature of 20-30° C., at a standard atmospheric pressure, and allowing the acetone to evaporate naturally, to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com