Graphene-based nano particle composite hydrogel and preparation method thereof

A composite hydrogel and nanoparticle technology, which is applied in the field of graphene-based nanoparticle composite hydrogel and its preparation, can solve problems such as threat, mechanical property impact, component residue, etc., achieve good mechanical properties, simplify the reaction process, The effect of simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

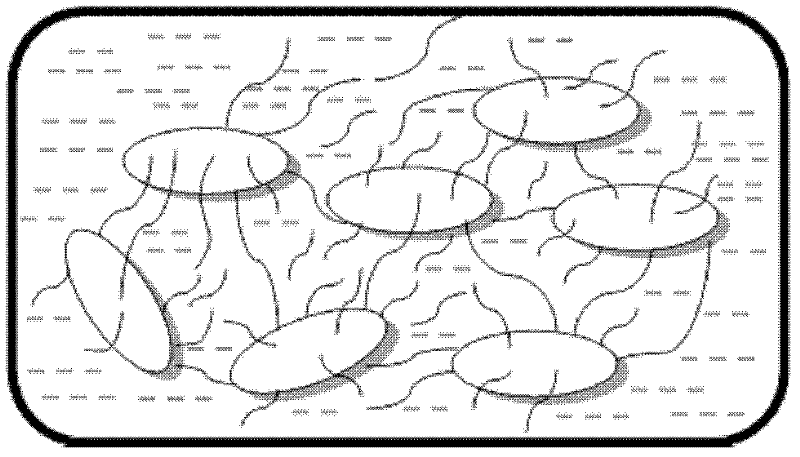

[0031] According to a typical embodiment of the present invention, the graphene-based nanoparticle composite hydrogel. The graphene-based nanoparticle composite hydrogel is composed of graphene-based nanoparticles, water-soluble polymers, and water, wherein the water-soluble polymer contains carbon-carbon double It is polymerized from water-soluble monomers with bonds, and cross-linked with graphene-based nanoparticles as the cross-linking center. Since the graphene-based nanoparticle composite hydrogel is only formed by the three-part reaction of graphene-based nanoparticles, soluble monomers, and water, there are no residues of other components, which minimizes potential threats to applications in biological and other fields; and When the graphene-based nanoparticle composite hydrogel is swollen to a high water content or reaches a swelling equilibrium, it can still maintain good mechanical properties.

[0032] The above-mentioned water-soluble monomer only needs to contain...

Embodiment 1

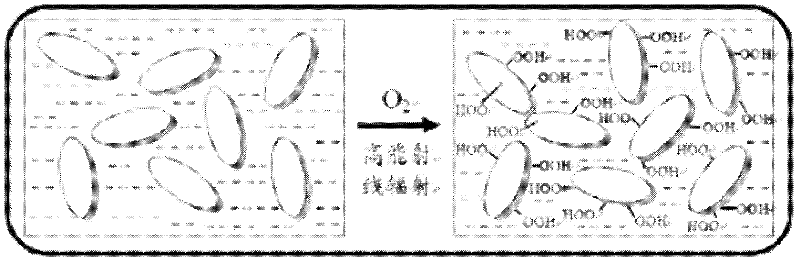

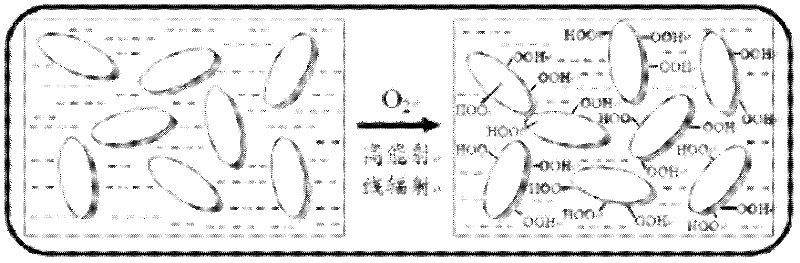

[0042] The uniformly dispersed 0.1wt% graphite oxide colloidal solution was irradiated with a cobalt source in an oxygen atmosphere for 4 hours, the irradiation temperature was 100°C, the irradiation dose rate was 0.2kGy / min, and the irradiation solution was measured after the pre-irradiation 10mL, mix it with acrylamide monomer (2.843g), and the concentration of the obtained acrylamide is 4mol / L. After 30 minutes of deoxygenation with nitrogen, seal the container holding the mixed solution and heat it. The reaction temperature is 80°C. The product is available after 24 hours. At room temperature, the beam speed is controlled at 40mm / min, and the tensile and compressive strength tests are carried out with an electronic universal testing machine. The measurement results are: the water content of the sample is 75%, its tensile strength at break is 0.2 MPa, its elongation at break is 600%, and its compressive strength at 95% compression ratio is 2.50 MPa.

Embodiment 2

[0044] The uniformly dispersed 0.15wt% graphite oxide colloidal solution was irradiated with a cobalt source under an oxygen atmosphere for 10 hours, the irradiation temperature was 40°C, and the irradiation dose rate was 0.25kGy / min. Mix 5 mL each evenly, the concentration of acrylic acid is 3 mol / L, and after purging nitrogen for 20 minutes, seal the container holding the mixed solution and heat it. The reaction temperature is 45°C, and the product is obtained after 36 hours of reaction. Under room temperature conditions, the beam speed is controlled at 20mm / min, and the tensile and compressive strength tests are carried out with an electronic universal testing machine. The measurement results are: the water content of the sample is 70%, its tensile strength at break is 0.3 MPa, its elongation at break is 2400%, and its compressive strength at 95% compression ratio is 20.55 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile breaking strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com