Method for preparing graphene biosensor

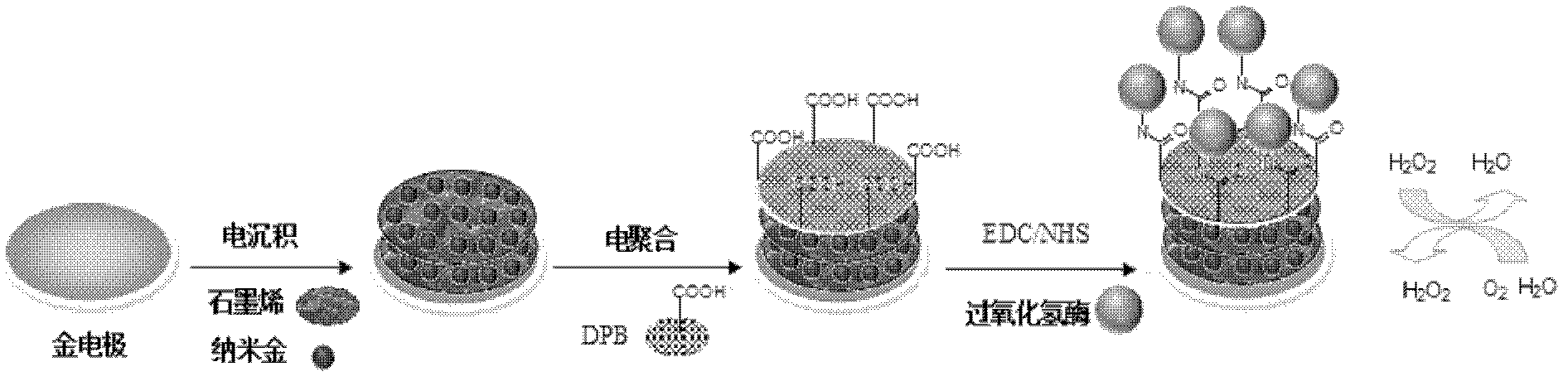

A biosensor, graphene technology, applied in the field of electrochemistry, can solve the problems of poor sensor reproducibility, low sensitivity, easy detachment of graphene and enzymes, etc., to overcome the easy detachment of enzymes or antibodies, good repeatability, and size The effect of precise control of distribution density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

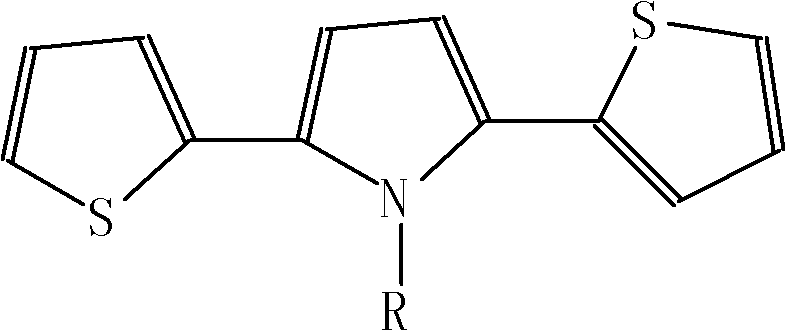

[0025] Immerse the treated gold electrode in 0.05mg / mL graphene oxide dispersion, control the potential at -1.2V for 50s at 20°C, take out the electrode, wash it with water, dry it at room temperature, and place it in 0.05mmol / L chlorine Electrodeposition was carried out at -0.25V for 50s at 20°C in gold acid solution, and the electrode was taken out, washed with water, and dried at room temperature. After 20 cycles of the above electrodeposition operation, the modified electrode was placed in 3 mL containing 2,5-bis(2-thiophene)-1-pyrrole p-benzoate (1 mmol / L) and tetrabutylammonium perchlorate (0.1 mol / L). L) in dichloromethane solution, control the potential between 0 and 1V to carry out polymerization by cyclic voltammetry, scan six times at a rate of 100mV / s, take out the electrode, wash with water, and dry at room temperature. The modified electrode was activated in 20mmol / L EDC / NHS solution for 4h, and then soaked in 10mg / mL catalase for 24h, the detection limit of the ...

Embodiment 2

[0027] Immerse the treated gold electrode in 0.02mg / mL graphene oxide dispersion, control the potential at -1.0V for 20s at 0°C, take out the electrode, wash it with water, dry it at room temperature, and place it in 0.01mmol / L chlorine Electrodeposition was carried out at -0.3V at 25°C for 40s in gold acid solution, and the electrode was taken out, washed with water, and dried at room temperature. After 30 cycles of the above electrodeposition operation, the modified electrode was placed in 3 mL containing 2,5-bis(2-thiophene)-1-pyrrole p-benzoate (1 mmol / L) and tetrabutylammonium chloride (0.1 mol / L ) in a dichloromethane solution, control the potential between 0 and 1V and carry out polymerization by cyclic voltammetry, scan six times at a rate of 200mV / s, take out the electrode, wash with water, and dry at room temperature. The modified electrode was activated in 20mmol / L EDC / NHS solution for 4h, and then soaked in 10mg / mL glucose oxidase for 24h. The detection limit of th...

Embodiment 3

[0029] Immerse the treated gold electrode in a solution containing 0.02mg / mL graphene oxide and 0.1mol / L potassium chloride, control the potential at -1.0V for 20s at 40°C, take out the electrode, wash it with water, dry it at room temperature, and put it away. In 0.01mmol / L chloroauric acid solution, electrodeposit at -0.4V at 0°C for 20s at a controlled potential, take out the electrode, wash with water, and dry at room temperature. After 50 cycles of the above electrodeposition operation, the modified electrode was placed in 3 mL of 2,5-di(2-thiophene)-1-pyrrole p-benzoate (1.0 mmol / L) and tetraoctylamine tetrafluoroborate. In dichloromethane solution (0.1mol / L), the polymerization was carried out by controlling the potential between 0 and 1V by cyclic voltammetry, scanning six times at a rate of 300mV / s, taking out the electrode, washing with water, and drying at room temperature. The modified electrode was activated in 20mmol / L EDC / NHS solution for 4h, and then in 20mg / mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com