Nano nickel oxide/graphene composite electrode material as well as preparation method and application thereof

A composite technology of nano-nickel oxide and graphene, which is applied in the field of nanomaterials and electrochemical energy, can solve the problems of easy agglomeration of NiO nanomaterials, electrolyte pollution of the environment, and restrictions on commercial development, achieving high energy density, low cost, and high efficiency. The effect of power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

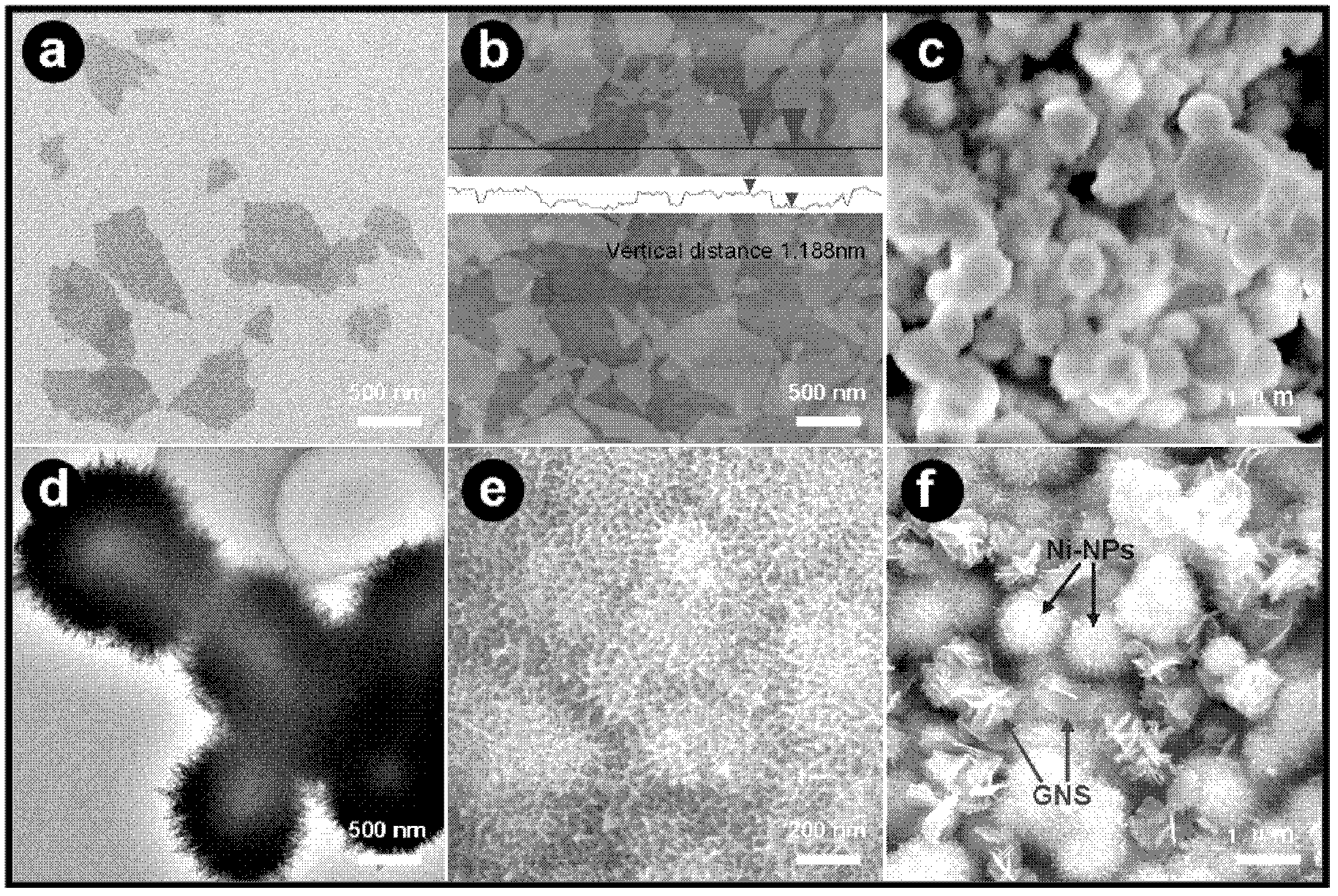

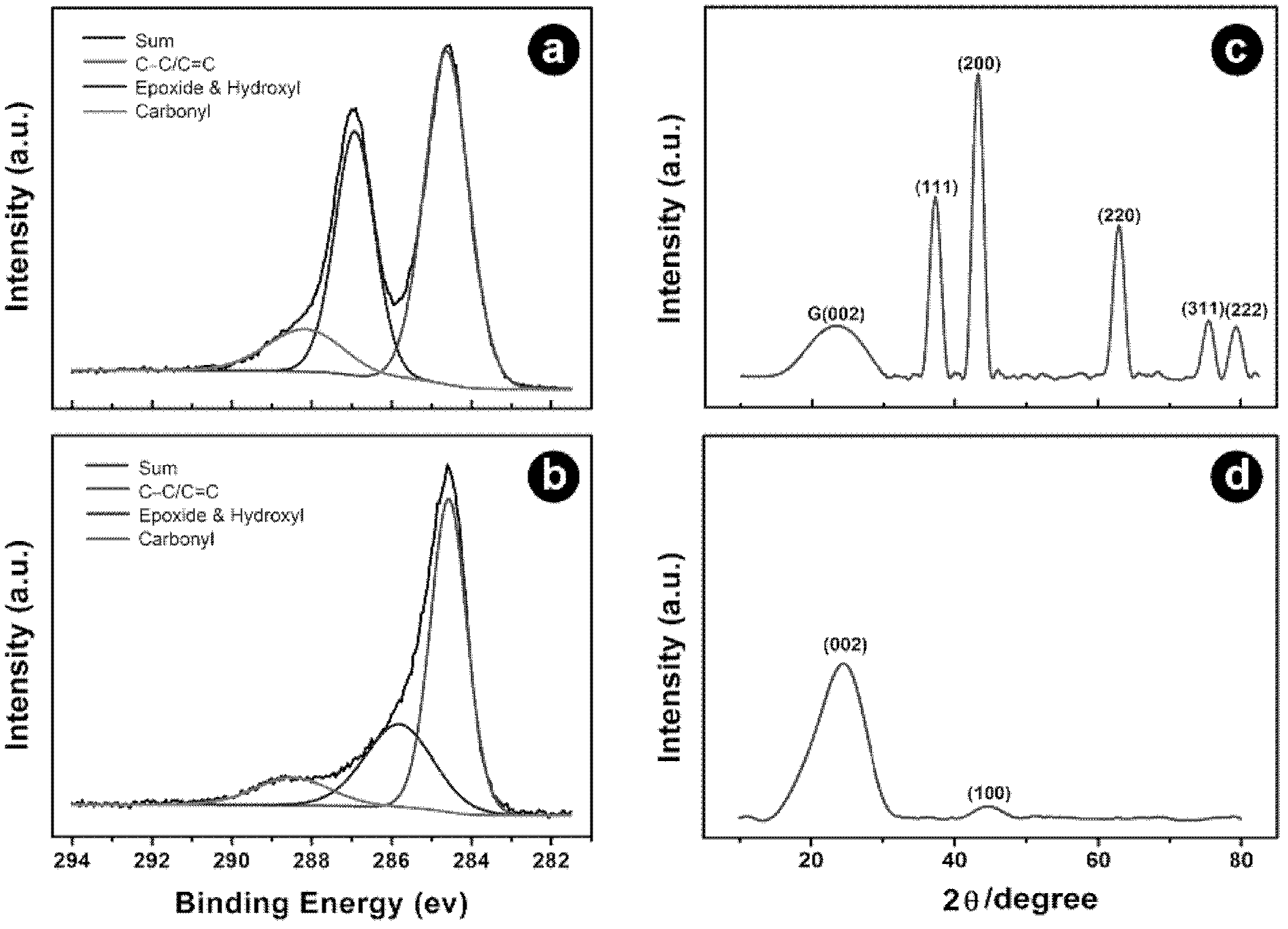

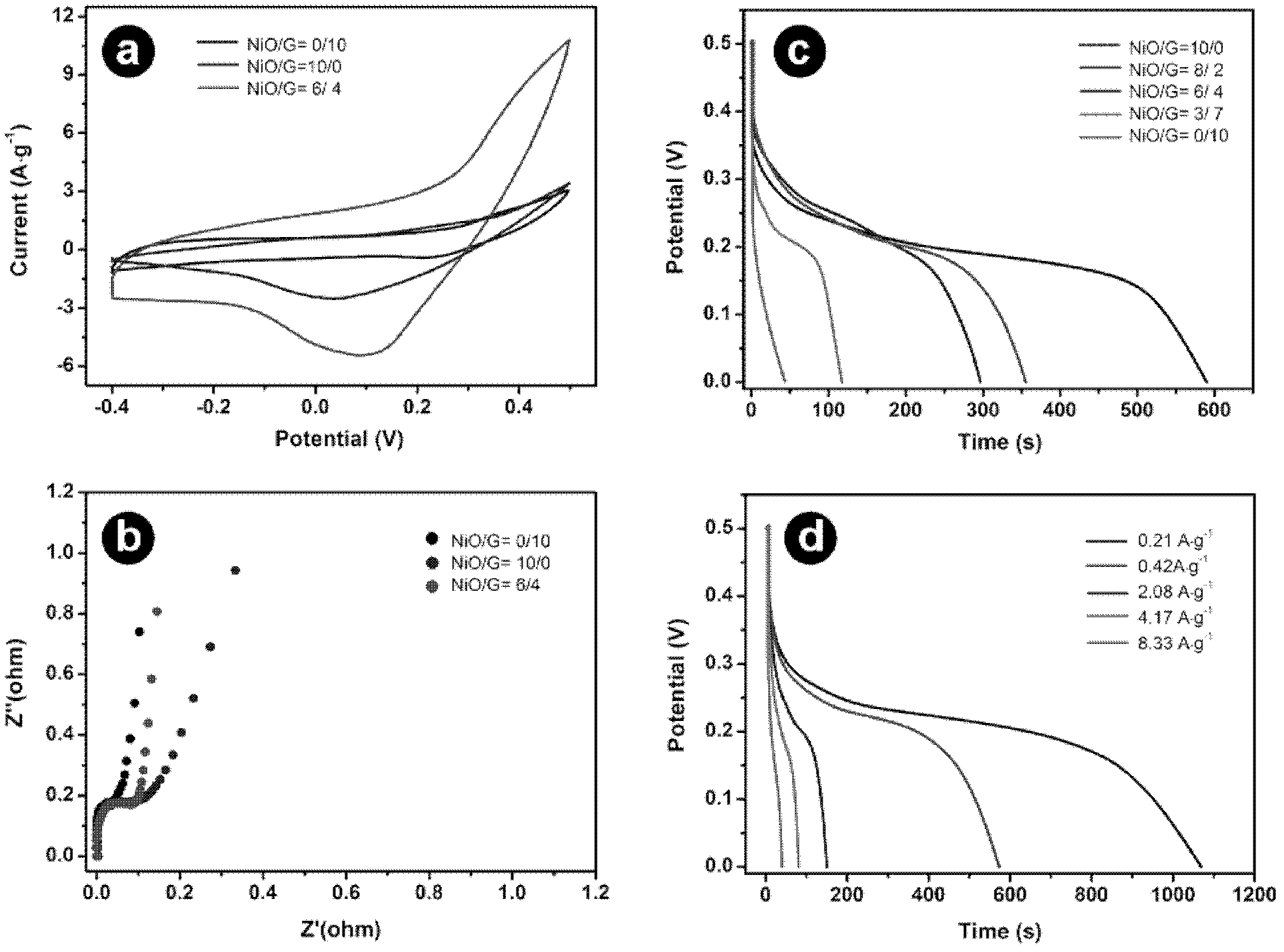

[0053] Take 20mL of 0.2M Ni(NO 3 ) 2 solution, added to the beaker, and then dripped into 18mL of 1M urea (CO(NH 2 ) 2 ), stirred at 90° C. for 6 hours, cooled rapidly to room temperature, precipitated, filtered, and the filter cake was washed 3 times with 50 mL of distilled water and 30 mL of absolute ethanol respectively. The solid product was dried under vacuum at 110°C for 5 hours and then heated to 300°C in air to obtain 180 mg of NiO.

[0054] Take 15 mg of the above-mentioned NiO, add it to the prepared 50 mL aqueous solution of graphene oxide with a concentration of 0.2 mg / mL, sonicate for 10 minutes, add 2 mL of hydrazine hydrate dropwise, stir and heat at 80 ° C for 5 hours, and naturally cool to room temperature. After centrifugation, the solid was washed three times with 30 mL of deionized water and 30 mL of ethanol, and the solid product was vacuum-dried at 90° C. for 6 hours to obtain 25 mg of a nickel oxide-graphene composite, that is, the weight ratio NiO / rG...

Embodiment 2

[0057] Take 20mL of 0.2M NiSO 4 solution, added to the beaker, and then dripped into 18mL of 1M urea (CO(NH 2 ) 2 ), stirred at 90° C. for 6 hours, cooled rapidly to room temperature, precipitated, filtered, and the filter cake was washed 3 times with 50 mL of distilled water and 30 mL of absolute ethanol respectively. The solid product was dried under vacuum at 110°C for 5 hours, and then heated to 300°C in air to obtain 208 mg of NiO.

[0058] Take 30mg of the above-mentioned NiO, add it to the prepared 38mL aqueous solution of graphite oxide with a concentration of 0.2mg / mL, sonicate for 10 minutes, add 2mL of hydrazine hydrate dropwise, stir and heat at 80°C for 5 hours, cool naturally to room temperature, and centrifuge Separated, the solid was washed three times with 30mL deionized water and 30mL ethanol respectively, and the solid product was vacuum-dried at 90°C for 6 hours to obtain 37.6mg of a nickel oxide-graphene composite, that is, the weight ratio NiO / rGO=4 / 1...

Embodiment 3

[0061] Take 20mL of 0.2M NiCl 2 solution, added to the beaker, and then dripped into 18mL of 1M urea (CO(NH 2 ) 2), stirred at 90° C. for 6 hours, cooled rapidly to room temperature, precipitated, filtered, and the filter cake was washed 3 times with 50 mL of distilled water and 30 mL of absolute ethanol respectively. The solid product was dried under vacuum at 110°C for 5 hours, and then heated to 300°C in air to obtain 117 mg of NiO.

[0062] Take 20mg of the above-mentioned NiO, add it to the prepared 230mL aqueous solution of graphite oxide with a concentration of 0.2mg / mL, sonicate for 10 minutes, add 5mL of hydrazine hydrate dropwise, stir and heat at 80°C for 5 hours, cool naturally to room temperature, centrifuge Separation, the solid was washed three times with 30mL deionized water and 30mL ethanol respectively, and the solid product was vacuum-dried at 90°C for 6 hours, and the product nickel oxide graphene composite was 66mg, that is, the weight ratio NiO / rGO=3 / 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com