Bisphenol A dummy template molecular imprinting stirring rod of and preparation method thereof

A technique of molecular imprinting and pseudo-template, applied in chemical instruments and methods, preparation of test samples, and other chemical processes, can solve problems such as template leakage, residual coating template molecules, and inaccurate measurement results, and achieve high Effects of selectivity, simplicity of materials, and simplicity of the alkylation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a bisphenol A pseudo-template molecularly imprinted stirring bar, comprising the following steps:

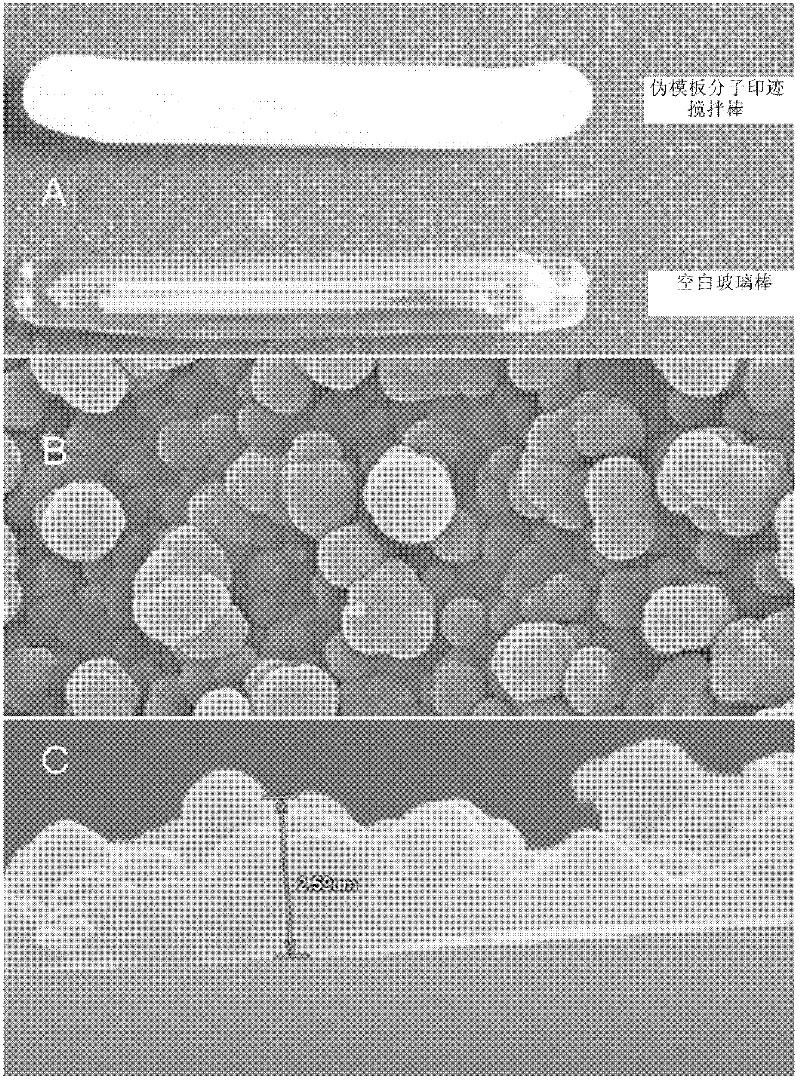

[0035] 1) Put an iron core in a glass rod (30mm×5mm i.d.), and sinter both ends ( figure 1 shown in A). The glass rod was successively treated with 1mol L before the alkylation treatment -1 NaOH solution and 0.1mol L -1 Soak in hydrochloric acid solution for 6 hours, then fully rinse with distilled water, and finally, place the activated glass rod in a vacuum drying oven, dry it at 120°C for 1 hour, and set it aside.

[0036] 2) Soak the glass rod treated in step 1) in an acetone solution of 10% (v / v) 3-(methacryloyloxy)propyltrimethoxysilane for 2 hours, rinse with methanol, and blow dry with nitrogen, as a coated carrier.

[0037] 3) Preparation of pre-polymerization solution: In 3 mL of methanol, sequentially add 1 mmol of tetrabromobisphenol A, 2 mmol of tetravinylpyridine, 4 mmol of ethylene glycol dimethacrylate and 30 mg of azobisisobutyr...

Embodiment 2

[0040] Embodiment 2 Adsorption experiment control example

[0041] The commercially available non-molecularly imprinted stirring rod --- PDMS stirring rod (purchased from Dexiang Technology Co., Ltd.), and the bisphenol A pseudo-template molecularly imprinted stirring rod prepared in Example 1 were respectively subjected to adsorption tests under the same conditions. Conditions: Dilute 6mL of milk to 30mL, and adjust the pH to 6-7. Put a stirring rod in the solution, and adsorb at 300 rpm for 1 to 2 hours under the condition of 20°C to 25°C. After the adsorption is complete, use 1 mL of methanol to desorb the stirring rod. After the desorption liquid nitrogen was blown dry, it was reconstituted with 150 μL methanol, and the reconstituted solution was used for liquid phase detection.

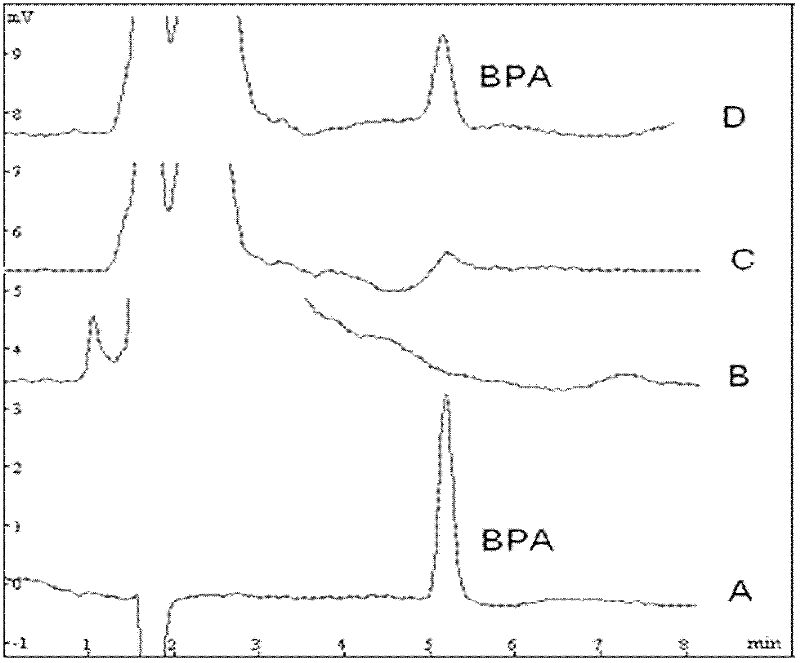

[0042] The result is as figure 2 As shown, before extraction, the chromatographic peak of bisphenol A cannot be seen in the chromatogram of milk (shown in chromatographic curve B). After the...

Embodiment 3

[0044] Preparation method of bisphenol A pseudo-template molecularly imprinted stirring rod, glass rod activation using 0.5mol L -1NaOH solution and 0.05mol L -1 Soak the hydrochloric acid solution for 10 hours; soak the glass rod in the acetone solution of 15% by volume of 3-(methacryloyloxy)propyltrimethoxysilane for 4 hours, the quality of azobisisobutyronitrile is tetrabromobisphenol A, tetravinylpyridine , 3% of the mass sum of ethylene glycol dimethacrylate. All the other are the same as in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap