Preparation method of one-dimensional conductive polypyrrole/ concave-convex rod nanameter composite material

A technology of nano-composite materials and attapulgite, which is applied in the direction of non-metallic conductors and organic material conductors, can solve the problems of difficult dispersion of reaction raw materials and reagents, poor performance of composite materials, particle agglomeration, etc., and achieve uniform and controllable size, production Low-cost, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

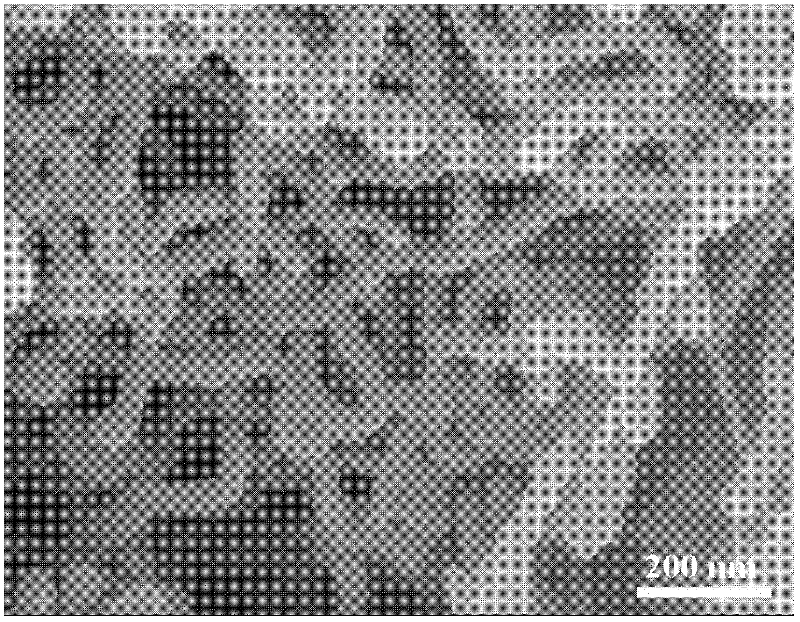

Image

Examples

Embodiment 1

[0030] 1) Stir nano-attapulgite powder (attapulgite particles with a diameter of 20nm to 100nm and a length of 0.3μm to 3μm) and deionized water at a rate of 1000 rpm to make attapulgite powder. 3% suspension;

[0031]2) Under the condition of constant stirring, add pyrrole to the suspension in step 1), the weight ratio of the amount of pyrrole added to the nano-attapulgite powder is 10:1, and then add hexadecyl trimethazine to the suspension Ammonium bromide and camphorsulfonic acid, the mol ratio of cetyltrimethylammonium bromide and pyrrole is 1: 1, and the mol ratio of camphorsulfonic acid and pyrrole is 1: 1, obtains mixed solution;

[0032] 3) Slowly drip an aqueous ammonium persulfate solution with a concentration of 2 mol / L into the mixed solution in step 2), the molar ratio of ammonium persulfate to pyrrole is 1:1, the duration of dripping is 0.5 hours, and oxidize at 5°C Polymerize for 5 hours, filter after the polymerization reaction, wash with water twice, and vac...

Embodiment 2

[0035] 1) Stir nano-attapulgite powder (attapulgite particles with a diameter of 20nm to 100nm and a length of 0.3μm to 3μm) and deionized water at a rate of 1000 rpm to make attapulgite powder. 0.2% suspension;

[0036] 2) Under the condition of constant stirring, add pyrrole to the suspension in step 1), the weight ratio of the amount of pyrrole added to the nano-attapulgite powder is 20:1, and then add dodecyl trimethazine to the suspension Ammonium bromide and dodecylbenzenesulfonic acid, the mol ratio of dodecyltrimethylammonium bromide and pyrrole is 2: 1, the mol ratio of dodecylbenzenesulfonic acid and pyrrole is 2: 1, get mixed solution;

[0037] 3) Slowly drip an aqueous ammonium persulfate solution with a concentration of 0.2 mol / L into the mixed solution in step 2), the molar ratio of ammonium persulfate to pyrrole is 2:1, and the duration of the dripping is 1 hour. After oxidative polymerization for 3 hours, after the polymerization reaction, it was filtered, wa...

Embodiment 3

[0040] 1) Stir nano-attapulgite powder (attapulgite particles with a diameter of 20nm to 100nm and a length of 0.3μm to 3μm) and deionized water at a rate of 1000 rpm to make attapulgite powder. Suspension with a content of 4.9%;

[0041] 2) Under the condition of constant stirring, add pyrrole to the suspension in step 1), the weight ratio of the amount of pyrrole added to the nano-attapulgite powder is 5: 1, then add methyl orange and twelve Sodium alkylsulfonate, the molar ratio of methyl orange and pyrrole is 0.2:1, and the molar ratio of sodium dodecylsulfonate and pyrrole is 0.5:1 to obtain a mixed solution;

[0042] 3) Slowly drip into the mixed solution in step 2) a concentration of 1mol / L ferric chloride aqueous solution, the molar ratio of ferric chloride to pyrrole is 0.8:1, the duration of dripping is 0.5 hours, at 0 ℃ oxidative polymerization for 24 hours, filtered after the polymerization reaction, washed 4 times with water, and vacuum dried at 90 ℃ for 5 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com