Preparation and classification method of para-aramid pulp

A technology of para-aramid pulp and grading method, which is used in cellulose raw material pulping, textile and papermaking, papermaking and other directions, can solve the problem of wide distribution of pulp thickness, unstable pulp diameter and aspect ratio, and inability to guarantee Pulp quality meets the needs of downstream products and other issues to achieve the effect of reducing static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

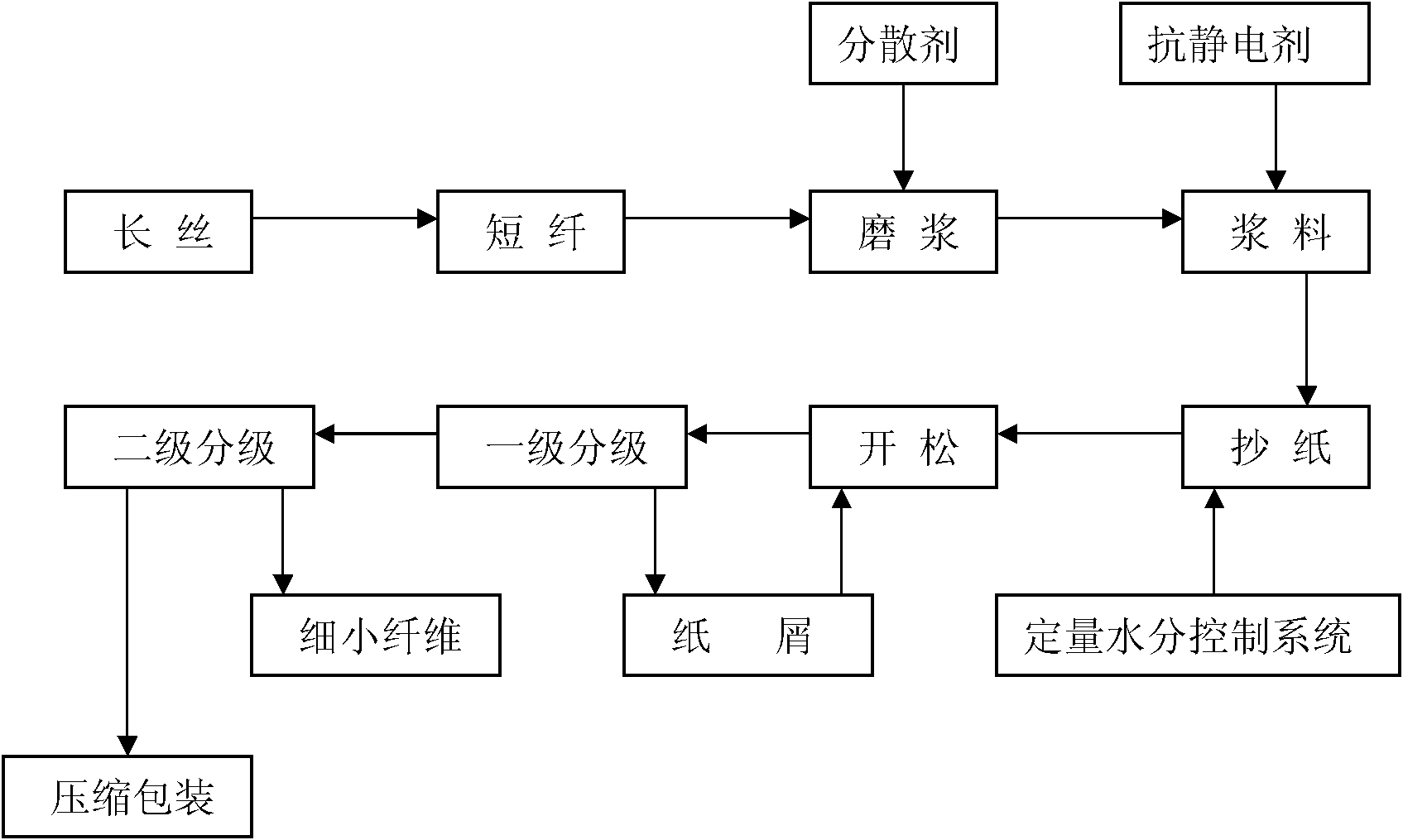

[0019] Such as figure 1 As shown, the para-aramid filament is mechanically cut into short fibers with a length of 8 mm, and added to an aqueous solution of polyoxyethylene oleate with a mass concentration of 1% to form a uniform suspension with a mass concentration of short fibers of 2%. Liquid, through the high-consistency disc refiner for defrosting, interrupting and brooming, the refining time is 120min, adding antistatic agent stearylamine polyoxyethylene ether in the slurry, the mass concentration of antistatic agent is 1%, through papermaking Machine dehydration and drying to make cardboard with a dryness of 95%. The cardboard is opened by an opener to obtain para-aramid pulp. The opened pulp is classified by a cyclone separator, and the first-stage separator The diameter is 4m, the height is 7.8m, and the pressure is 5.5KPa. The diameter of the secondary separator is 2.5m, the height is 5m, and the pressure is 3.5KPa. The first stage cyclone separator adopts upper feedi...

Embodiment 2

[0021] Cut para-aramid filaments into short fibers with a length of 4 mm by mechanical cutting, and add them to an aqueous solution of 0.5% polyoxyethylene oleate to form a uniform suspension with a mass concentration of short fibers of 1%. The disc refiner is used for defrosting, interrupting and brooming. The refining time is 180min. Add antistatic agent stearylamine polyoxyethylene ether to the slurry. The mass concentration of antistatic agent is 0.5%. Dried to make a cardboard with a dryness of 94%. The cardboard is opened by an opener to obtain para-aramid pulp. The opened pulp is classified by a cyclone separator. The diameter of the primary separator is 4m. The height is 7m, the pressure is 5.5KPa, the diameter of the secondary separator is 2.5m, the height is 6m, and the pressure is 4KPa. After classification, the content of paper dust is reduced by 80%, and the content of fine fibers with a length of less than 0.1mm is reduced by 65%, resulting in an average length o...

Embodiment 3

[0023] Cut para-aramid filaments into short fibers with a length of 4 mm by mechanical cutting, and add them to an aqueous solution of fatty alcohol polyoxyethylene ether methyl silane with a mass concentration of 0.5% to form a uniform suspension with a mass concentration of short fibers of 1.5% Liquid, through the double-disk disc refiner to decompose, interrupt and broom, the refining time is 150min, add antistatic agent sorbitol in the slurry, the mass concentration of antistatic agent is 0.5%, dehydrate and dry through the paper machine The cardboard with a dryness of 94% is made, and the cardboard is opened by an opener to obtain para-aramid pulp. After opening, the pulp is classified by a cyclone separator. The diameter of the primary separator is 3m, and the height The diameter of the secondary separator is 3m, the height is 6m, and the pressure is 3.5KPa. The first-stage cyclone separator adopts upper feeding, and the second-stage cyclone separator adopts intermediate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com