Method for removing mercury ions from water by using silver-modified magnetic carbon nanotube and regeneration method

A magnetic carbon nanotube, carbon nanotube technology, applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of difficult separation of adsorbent materials and water bodies, limited adsorption capacity, and difficulty in handling adsorbents. The possibility of avoiding secondary pollution, saving processing time and cost, and improving the effect of environmental and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 Activation of carbon nanotubes

[0045] ①Take 1.0g of carbon nanotube material, put it in a 60mL autoclave, add 20mL of concentrated nitric acid with a concentration mass fraction of 65-68%, and seal the autoclave;

[0046] ②Put the high-pressure reactor containing the above reactants in an oven, keep it at 100°C for 10 minutes, then rapidly raise the temperature to 150°C, and react for 1.0h. After the reaction is complete, stop heating and cool down to room temperature naturally;

[0047] ③Take it out from the oven and open the reaction kettle, pour out the remaining waste acid, and wash the reaction product with deionized water until the cleaning solution is neutral;

[0048] ④ The above product was dried at 100° C. for 4 hours to obtain activated multi-walled carbon nanotubes for future use.

Embodiment 2

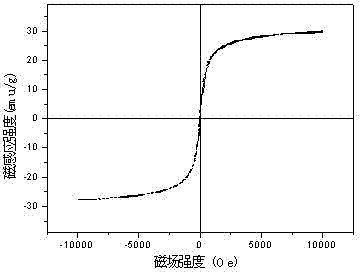

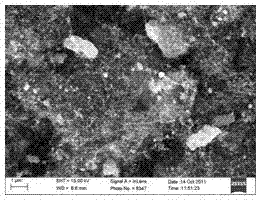

[0049] Example 2 Magnetically Modified Carbon Nanotubes

[0050] The magnetic modification reaction is carried out under the condition of ultrasonic wave and nitrogen protection, and the reaction temperature is 50°C;

[0051] Take 1.0g of the activated carbon nanotube material and suspend it in 200mL of an aqueous solution containing 1.7g (NH4)2Fe(SO4)2·6H2O and 2.5gNH4Fe(SO4)2·12H2O. In the mixed solution of the reaction system, iron / (iron+carbon nanotube) is 35%, and the product is recorded as 35% Fe magnetically modified carbon nanotube;

[0052] The above system was placed under ultrasonic conditions with an ultrasonic frequency of 40KHz, an ultrasonic power of 250W, and a heating power of 400W for 10 minutes. During the reaction, 8mol / L ammonia water was added dropwise to keep the pH of the mixture at 11-12;

[0053] After the acoustic reaction, the reaction system was placed in a constant temperature water bath at 50°C for 60 minutes, and stirred at a constant speed of ...

Embodiment 3

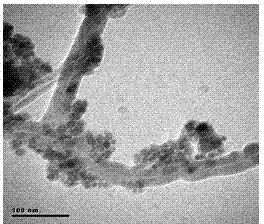

[0055] Example 3 Silver Nanoparticle Loading

[0056] Take 0.2 g of the iron oxide magnetically modified carbon nanotube material obtained in Example 2, and sonicate it in 50 ml of DMF / H2O mixed solution. Ultrasonic is carried out at an ultrasonic frequency of 40KHz, ultrasonic power of 250W, and room temperature of 20°C, and disperses for 1 h. . The volume ratio of DMF to H2O is 1:1;

[0057] ②Put 100mL solution containing 0.034 g AgNO3 and 100mL solution containing 0.1764 g trisodium citrate into a 500 ml beaker, stir vigorously and mix thoroughly;

[0058] ③ Freshly prepare 500mmol / L NaBH4 solution, place it in an ice-water bath, and set aside;

[0059] ④ Under the condition of vigorous stirring, use a pipette to add 2 ml of 500 mmol / L NaBH4 solution to the beaker containing AgNO3 solution and trisodium citrate solution drop by drop, and keep stirring for 5 minutes to obtain a silver colloidal solution;

[0060] ⑤ Add the mixed solution of iron-containing oxide magnetica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com