Method for collecting, separating, storing, transporting and reutilizing kitchen waste

A technology of food waste and garbage, which is applied in the field of harmless volume reduction and recycling of food waste, can solve the problems of high processing cost, high energy consumption, and large energy consumption, and achieve the goal of overcoming environmental pollution and operating Reliable, effective treatment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

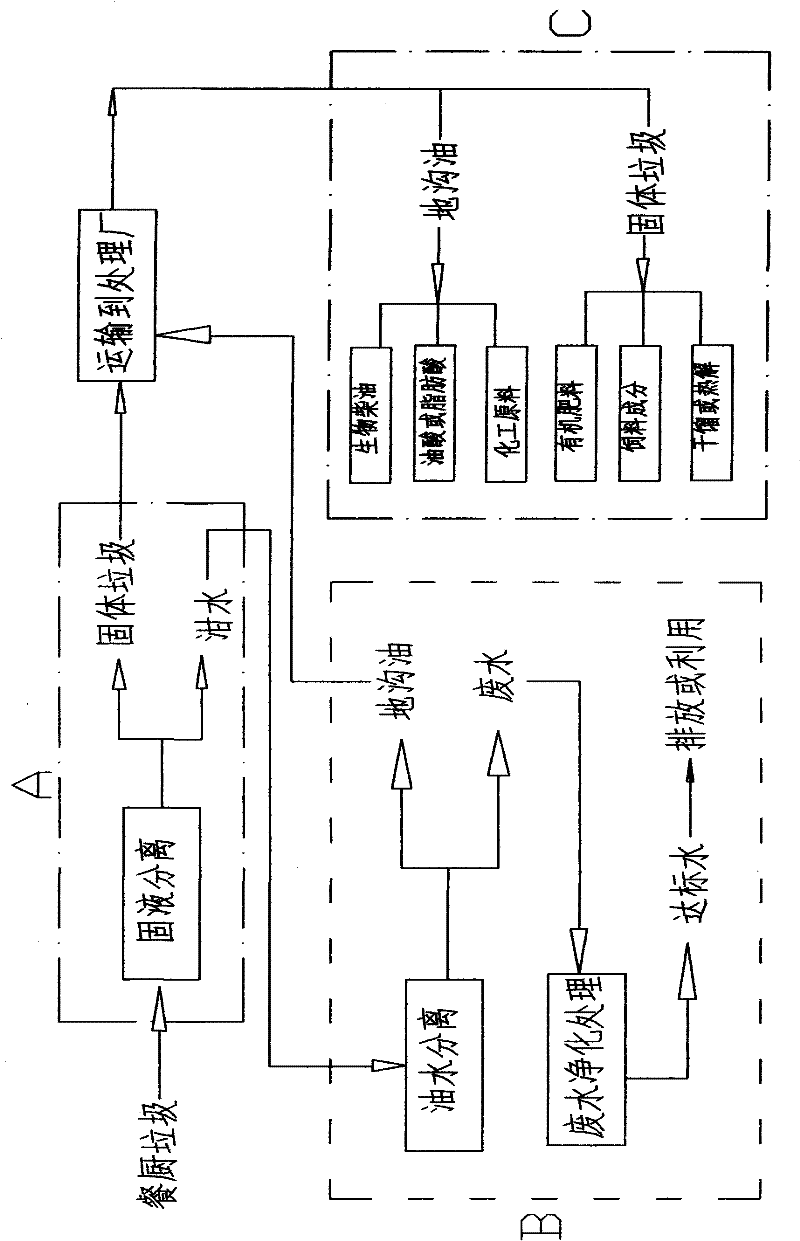

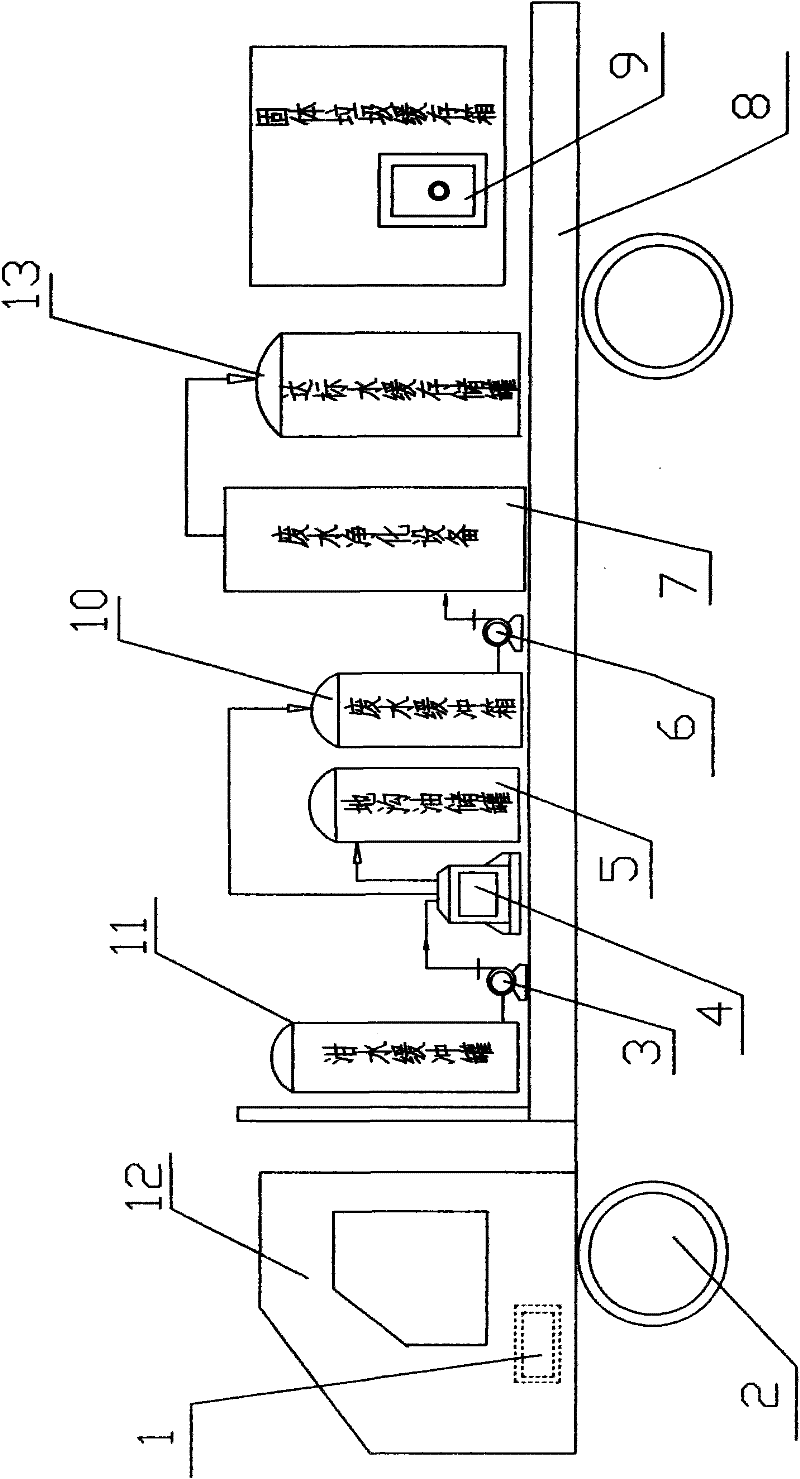

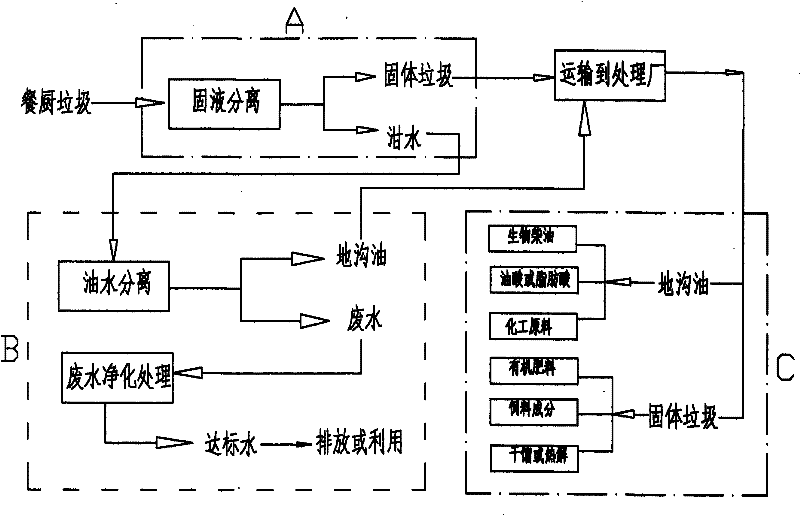

[0041] as attached figure 1 And attached figure 2 Shown, in one embodiment of the present invention, but the present invention is not limited thereto; The method of the present invention comprises: Carrying out the on-site solid-liquid separation of food waste in restaurants; The oil-water separation and wastewater purification treatment are discharged on-site after reaching the standard; then, the waste oil and solid food waste are transported to the waste treatment plant for harmless and volume-reducing treatment of the solid part of the food waste and resource utilization of the waste oil;

[0042] The specific steps are:

[0043] i). On-site solid-liquid separation of food waste in restaurants:

[0044] The kitchen staff continuously pour a total of 102 kg of leftover food... and other food waste into the filter bag on the upper part of the food waste separation equipment. In this embodiment, a diameter of 60 cm is selected. , a cylindrical solid-liquid separation equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com