Method for treating externally-autoplastic autogenous skull sheet

A technology of autologous transplantation and treatment method, which is applied in the field of biomaterials and can solve problems such as rejection, clinical application failure, and inability to fully meet clinical needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0026] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples;

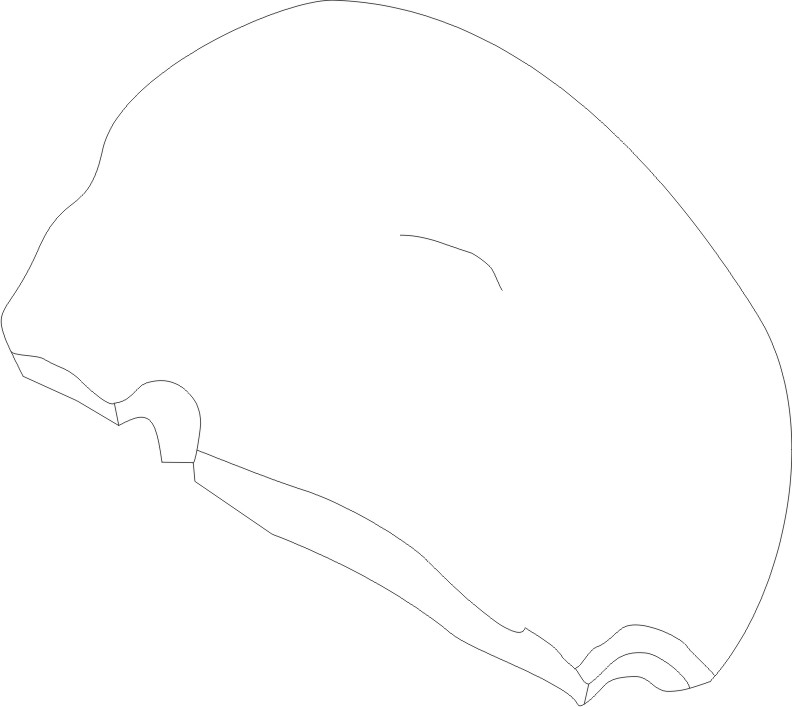

[0027] After the fresh bone flap is taken out in a clean environment, it is placed in the refrigerator at -10°C for 24 hours, and then rewarmed in a natural environment (about 20°C) for 48 hours; Ruptured, cells autolyzed. Use a brush to remove the residual periosteum, muscle, and fascia tissue on the surface of the skull, and rinse thoroughly with running water.

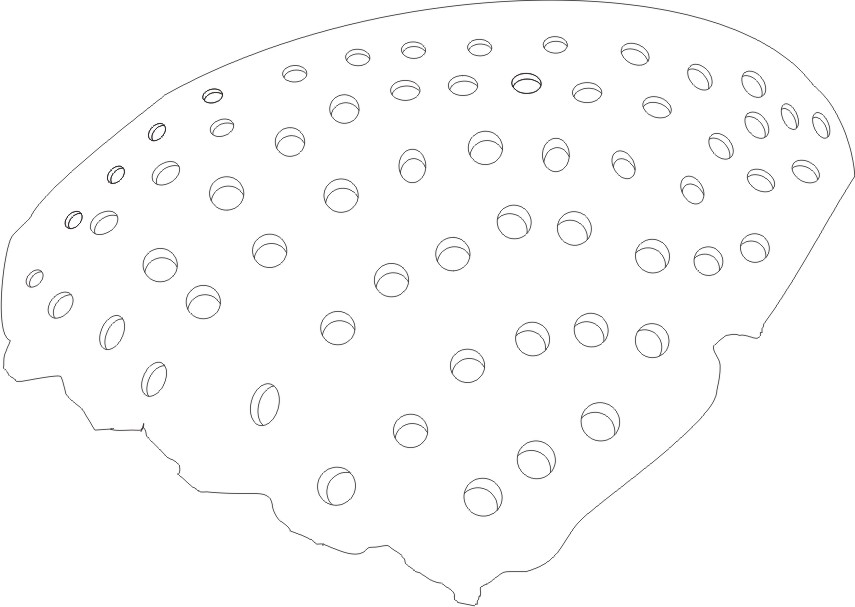

[0028] Use a drill bit with a diameter of 4mm to drill holes in the skull mesh, so that the area between the holes is about 1cm×1cm. When drilling, try to leave the bone suture as muc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com