Anionic dye adsorbent as well as preparation method and application thereof

An anionic dye and adsorbent technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of high cost of activated carbon method, poor treatment effect of chemical treatment method, etc. Ideal effect, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

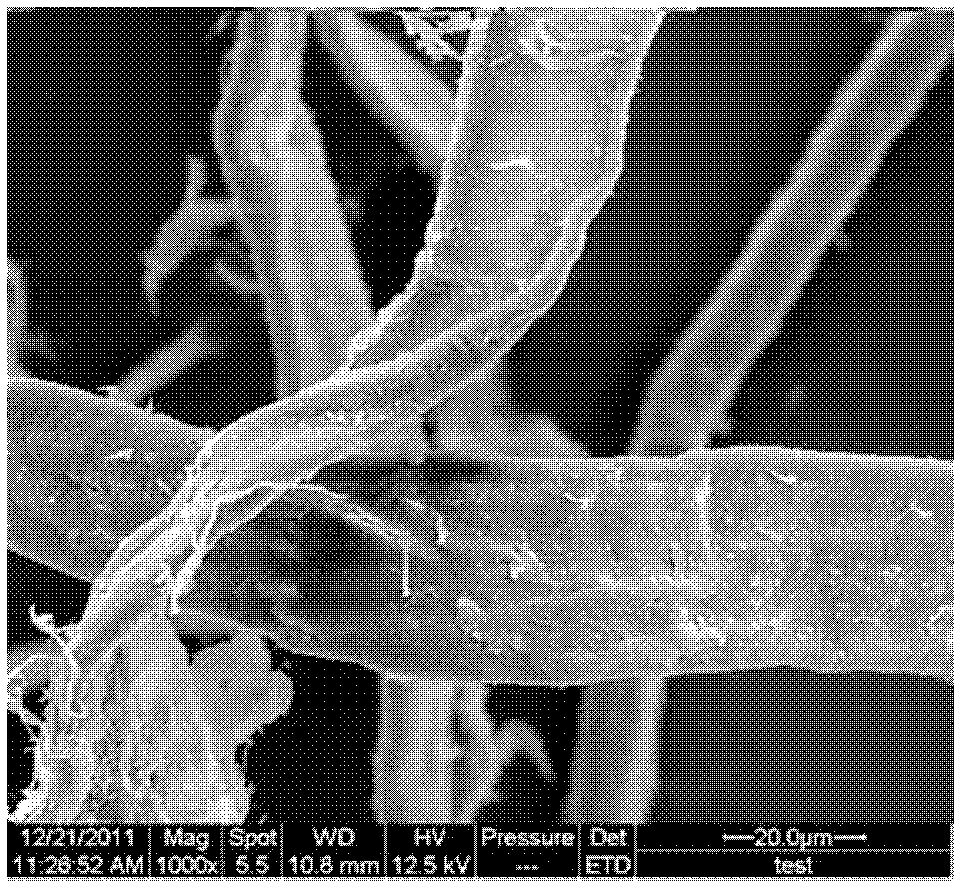

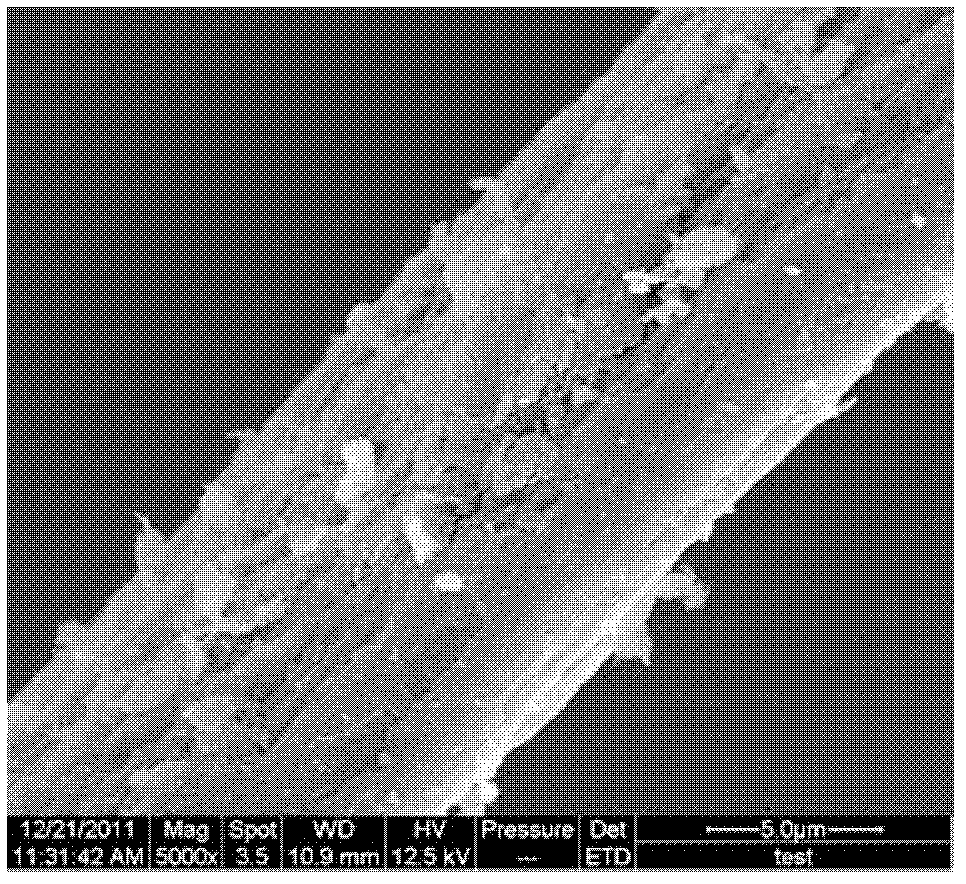

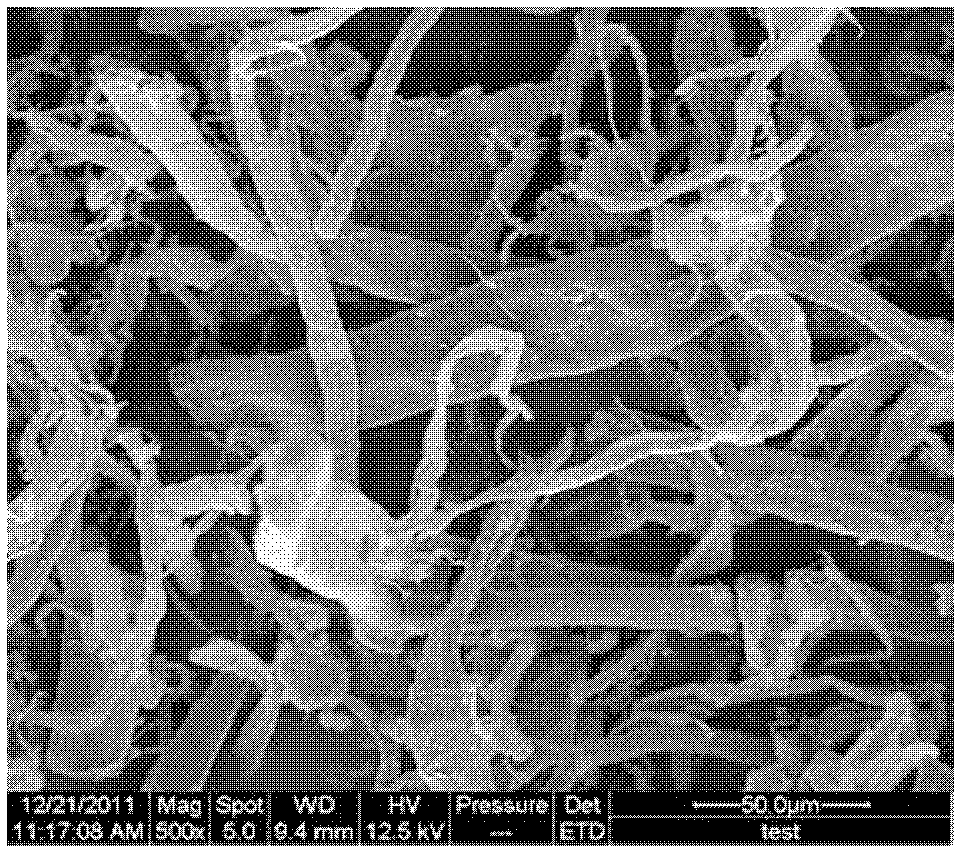

Image

Examples

specific Embodiment approach 1

[0036] Specific embodiment one: a kind of anionic dye adsorbent of the present embodiment is quaternary ammonium salt cellulose, and its structural formula is

[0037] Wherein n is a positive integer of 300-800.

[0038] The anionic dye adsorbent of this embodiment is added to the anionic dye wastewater to be treated, and after the anionic dye adsorbent reacts with the anionic dye in the water, it settles quickly in the form of co-precipitation. The operation is simple, no special equipment is required, the sedimentation speed is fast, the wastewater treatment efficiency is high, and the effect is ideal. No other harmful substances will be introduced during the treatment process, and no secondary pollution will be caused.

specific Embodiment approach 2

[0039] Specific embodiment two: the preparation method of the anionic dye adsorbent described in specific embodiment one is carried out according to the following steps:

[0040] 1. After deinking the waste newspaper fiber, crush it to 80-120 mesh to obtain the deinked waste newspaper fiber;

[0041] Two, the mass volume ratio of 20% sodium hydroxide by deinking waste newspaper fiber and mass concentration is 1g: 20~30mL, the mass ratio of deinking waste newspaper fiber and epichlorohydrin is 1: (5~15) , the volume ratio of epichlorohydrin and triethylamine is (1~4): the ratio of 1 weighs deinking waste newspaper fiber, mass concentration is 20% sodium hydroxide, epichlorohydrin and triethylamine;

[0042] 3. Add the deinked waste newspaper fibers weighed in step 2 and sodium hydroxide with a mass concentration of 20% into the container, stir at room temperature for 1h to 2h, and then adjust the pH value to be greater than 13 to obtain a turbid liquid;

[0043] 4. Add the epi...

specific Embodiment approach 3

[0047]Specific embodiment three: the difference between this embodiment and specific embodiment two is that the method for deinking the waste newspaper fiber described in the step one is: according to sodium hydroxide, hydrogen peroxide, sodium silicate, surfactant, waste newspaper Put it in a container at a mass ratio of 5:5:10:1:5:31 with distilled water, stir it in a water bath at 65°C for 1 hour, then wash it, and dry it at 60°C for 5 hours to complete deinking . Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com