Porous hydroxyapatite and preparation method and application thereof

A hydroxyapatite, uniform technology, applied in the field of medicine, can solve problems such as no relevant reports, and achieve the effects of good physical stability, inhibition of recrystallization, and improvement of drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

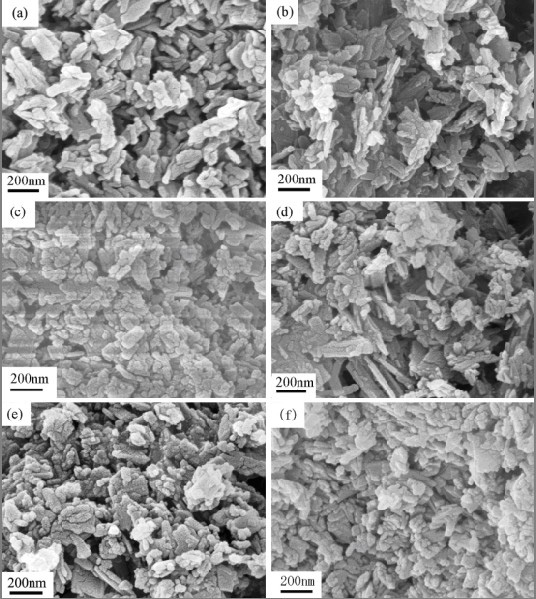

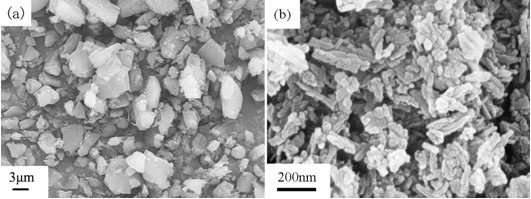

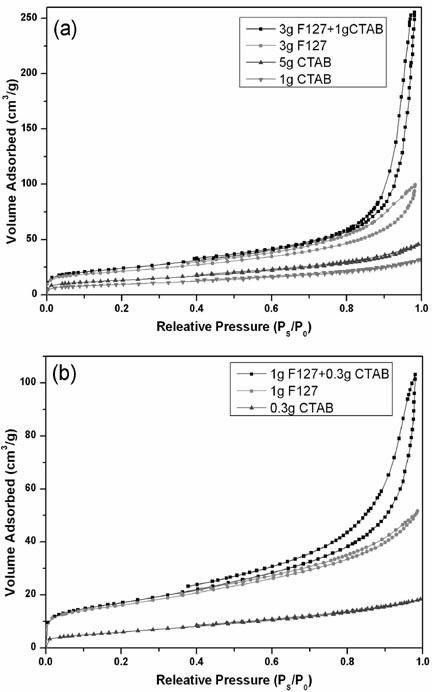

[0038] Accurately weigh 3g F127 and 1g CTAB into 100ml of water, heat to 80°C to dissolve completely, then add 2.775g of anhydrous calcium chloride and 1.980g of diammonium hydrogen phosphate (the molar ratio of calcium to phosphorus is 5:3), and use Adjust the pH of the solution to 10 with ammonia water, stir for 2 hours, make the solution fully mixed and react, put the reacted solution in an autoclave at 100°C for hydrothermal reaction for 24 hours, wash with deionized water and absolute ethanol three times until neutral, and use The precipitate was separated by suction filtration, dried in vacuum at 60°C for 24 hours, and calcined at 550°C for 6 hours to remove the organic template and finally obtain porous hydroxyapatite.

Embodiment 2

[0040] Accurately weigh 1g F127 and 0.3g CTAB into 100ml of water, heat to 70°C to dissolve completely, then add 2.775g of anhydrous calcium chloride and 1.980g of diammonium hydrogen phosphate (the molar ratio of calcium to phosphorus is 5:3), Adjust the pH of the solution to 11 with ammonia water, stir for 2 hours, make the solution fully mixed and react, put the reacted solution in an autoclave at 80°C for hydrothermal reaction for 24 hours, wash with deionized water and absolute ethanol three times until neutral, Vacuum drying at 50°C for 48 hours, high-temperature calcination at 500°C for 6 hours, removal of the organic template, and finally obtaining porous hydroxyapatite.

Embodiment 3

[0042] Accurately weigh 1g of F127 and 0.3g of CTAB and add it to 100ml of water and ethanol mixed solvent (and the ratio is 1:1), heat to 80°C to dissolve completely, then add 5.852g of calcium nitrate tetrahydrate and 1.980 of diammonium hydrogen phosphate g (the molar ratio of calcium to phosphorus is 5:3), adjust the pH of the solution to 10 with ammonia water, stir for 3 hours, make the solution fully mixed and react, put the reacted solution in an autoclave at 70°C for hydrothermal reaction for 24 hours, and use deionized water and anhydrous ethanol for three times to neutrality, vacuum drying at 50°C for 48 hours, high-temperature calcination at 500°C for 6 hours, removing the organic template and finally obtaining porous hydroxyapatite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com