Sodium chromate alkali solution impurity removal method and preparation method of chromic oxide

An alkaline solution, sodium chromate technology, applied in the directions of chromium trioxide, chromium oxide/hydrate, chromate/dichromate, etc., can solve the problems of trivalent chromium loss, difficult to elute chromium, etc. The effect of high conversion rate, low cost and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

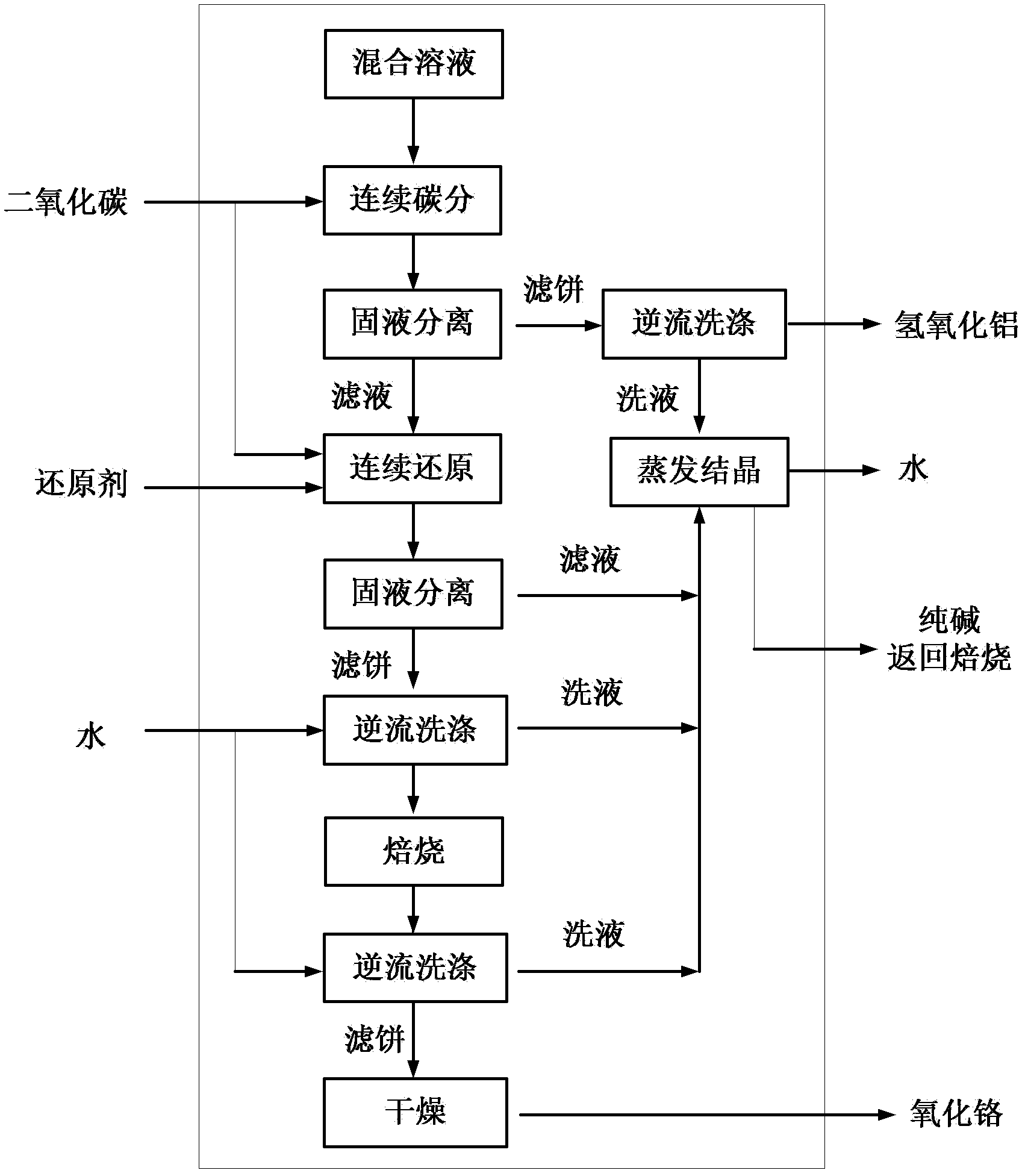

Method used

Image

Examples

Embodiment 1

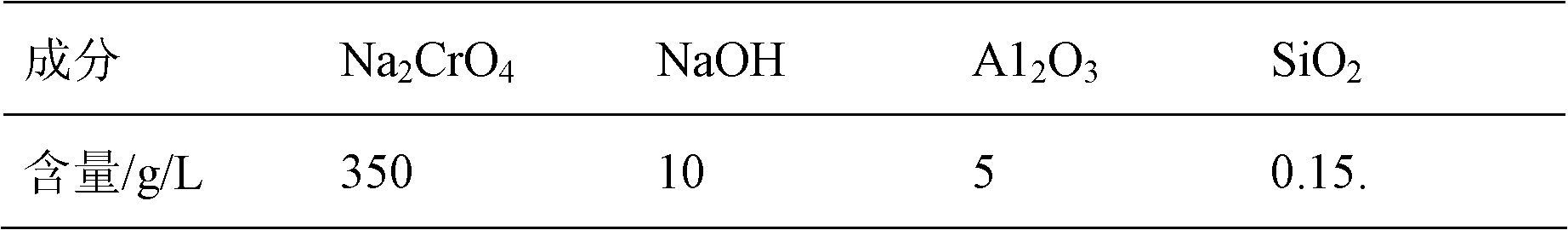

[0039] Select sodium chromate alkaline solution from a chromium salt factory

[0040]

[0041] The alkaline solution obtained by calcium-free roasting is pumped into the first tank of the continuous carbon separation tank, and the temperature of the first tank is controlled to be 80°C. into CO 2 (high purity CO 2 Mix with air, volume fraction 55%), add aluminum hydroxide seed crystal, seed crystal coefficient is 0.3, carry out continuous carbonization, fully increase CO 2 utilization rate. The carbon final tank is separately fed into CO 2 , to fully precipitate the silicon in the solution. The cumulative decomposition time is 2h. The removal rate of carbon and aluminum is 99.9%, and the removal rate of silicon is 98.5%.

[0042] The aluminum slime obtained after carbon separation was countercurrently washed 4 times at a temperature of 80°C for 15 minutes. After carbon separation, the filtrate obtained by filtering is mixed with potato starch and pumped into continuou...

Embodiment 2

[0045] Select sodium chromate alkaline solution from a chromium salt factory

[0046]

[0047] The alkaline solution obtained by calcium-free roasting is pumped into the first tank of the continuous carbon separation tank, and the temperature of the first tank is controlled to be 90°C. into CO 2 (lime kiln gas, purification, compression, volume fraction 38%), add aluminum hydroxide seed crystals, the seed crystal coefficient is 0.2, carry out continuous carbonization, fully increase CO 2 utilization rate. The carbon final tank is separately fed into CO 2 , to fully precipitate the silicon in the solution. The cumulative decomposition time is 3h. The removal rate of carbon and aluminum is 99.9%, and the removal rate of silicon is 99.1%.

[0048] The aluminum slime obtained after carbon separation was countercurrently washed 4 times at a temperature of 80°C for 15 minutes. After carbon separation, the filtrate obtained by filtering is mixed with pregelatinized starch an...

Embodiment 3

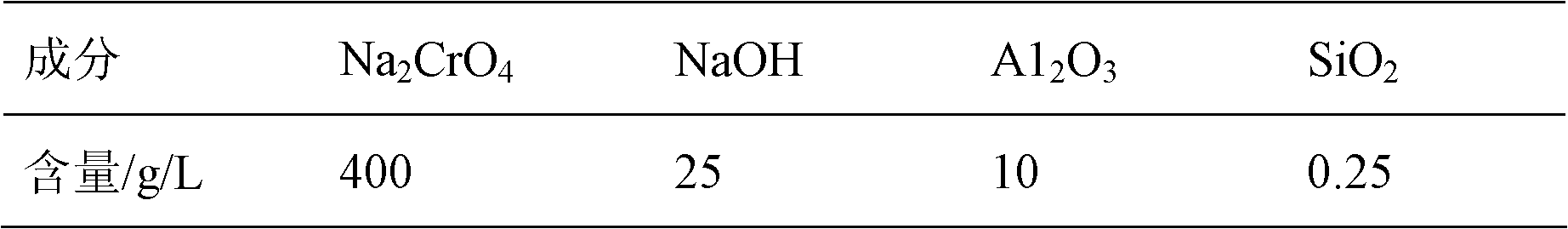

[0051] Select sodium chromate alkaline solution from a chromium salt factory

[0052]

[0053] The alkaline solution obtained by calcium-free roasting is pumped into the first tank of the continuous carbon separation tank, and the temperature of the first tank is controlled to be 85°C. into CO 2 (calcination kiln gas, purification, compression, volume fraction 38%), adding aluminum hydroxide seed crystals, the seed crystal coefficient is 0.4, continuous carbon content, fully increase CO 2 utilization rate. The carbon final tank is separately fed into CO 2 , to fully precipitate the silicon in the solution. The cumulative decomposition time is 3.5h. The removal rate of carbon and aluminum is 99.9%, and the removal rate of silicon is 99.4%.

[0054] The aluminum slime obtained after carbon separation was countercurrently washed 4 times at a temperature of 80°C for 15 minutes. After carbon separation, the filtrate obtained by filtering is mixed with dextrin and pumped in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com