Micro-structured optical fiber surface plasmon resonance sensor

A surface plasmon and resonance sensor technology, which is applied in the direction of cladding optical fiber, multi-layer core/cladding optical fiber, phase influence characteristic measurement, etc., can solve the problem that the spectral sensitivity is not too high, there is a depression in the center of the field Gaussian light source coupling difficulty and other issues, to achieve the effect of improving measurement accuracy, sensitivity, and fiber performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

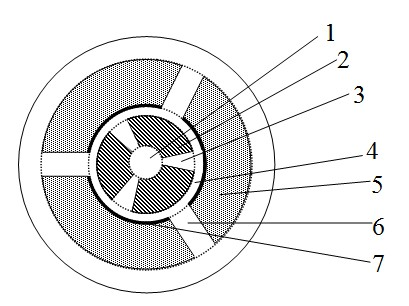

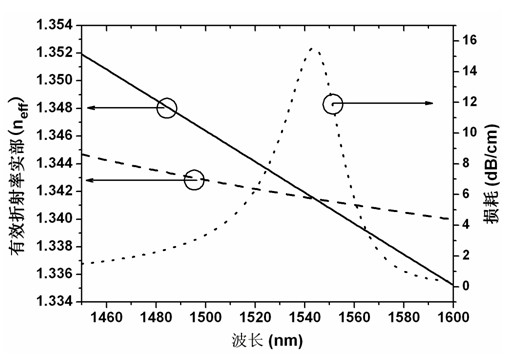

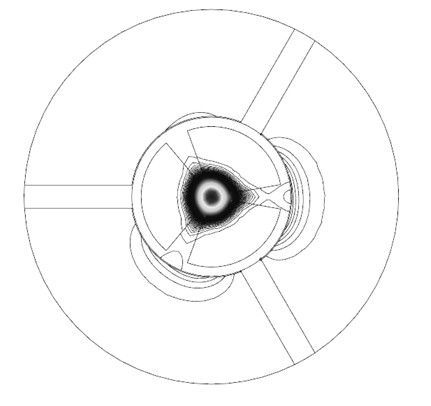

[0031] The structure of the optical fiber is as figure 1 As shown, the radius R of the core 1 is 0.86 μm, and the outer radius R of the inner annular cladding is 1 is 3.0μm, the outer radius R of the middle annular cladding 2 is 3.4μm, the outer radius R of the outer annular cladding 3 is 8.0 μm, the central angle corresponding to the fan ring support arm 3 in the inner ring cladding for 20 o , the number of fan-shaped support arms 3 and rectangular support arms 6 are respectively selected as 3, the refractive index of the substrate material is selected as 1.45, and the thickness of the gold film is d gold 40nm. When the refractive index of the analytical fluid is 1.330, the resonance wavelength is at 1543.8 nm. Within the measurement range of the refractive index of this analytical solution, the spectral sensitivity is higher than 1.05·10 4 nm·RIU ?1 , assuming that it is measured by a spectrometer with a resolution of 0.1nm, the corresponding refractive index sensing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com