Amorphous anode active material, preparation method of electrode using same, secondary battery containing same, and hybrid capacitor

A cathode active material and secondary battery technology, applied in the direction of active material electrodes, hybrid capacitors, hybrid capacitor electrodes, etc., can solve problems such as limited market expansion, and achieve excellent charge and discharge characteristics, high capacity, effective tracking and prediction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

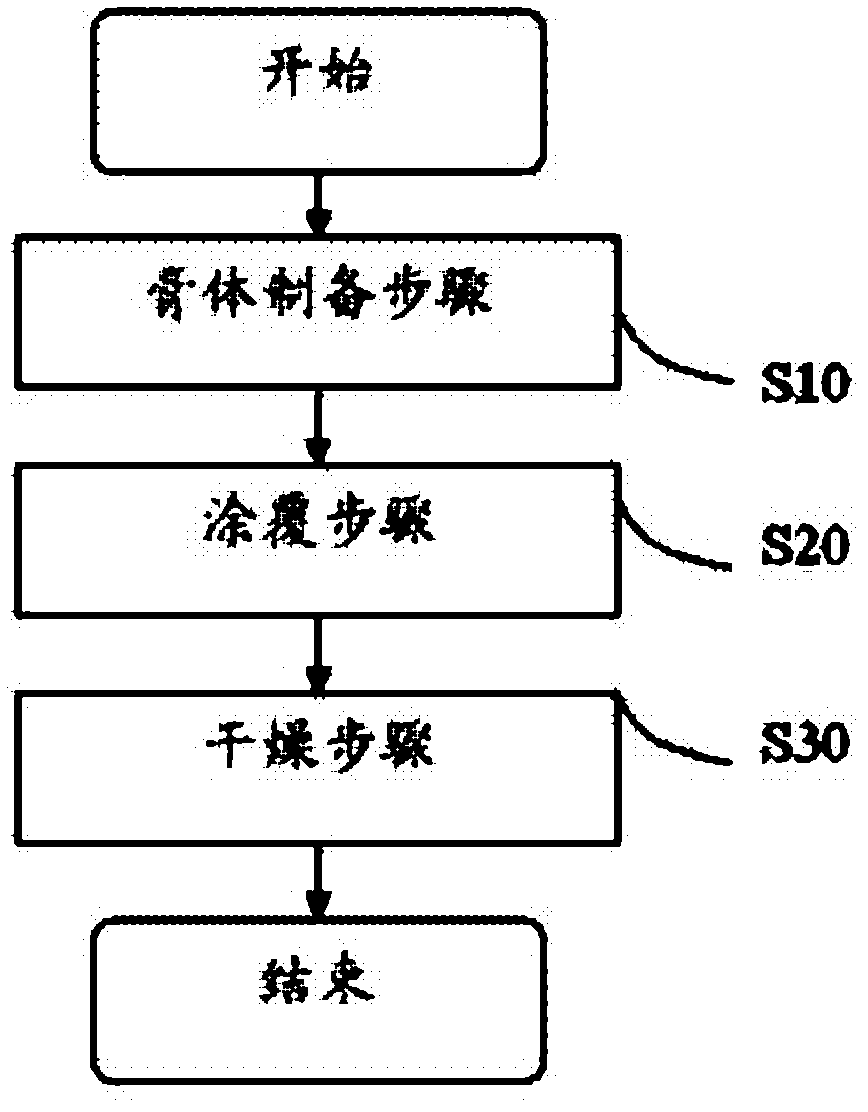

Method used

Image

Examples

Embodiment 1

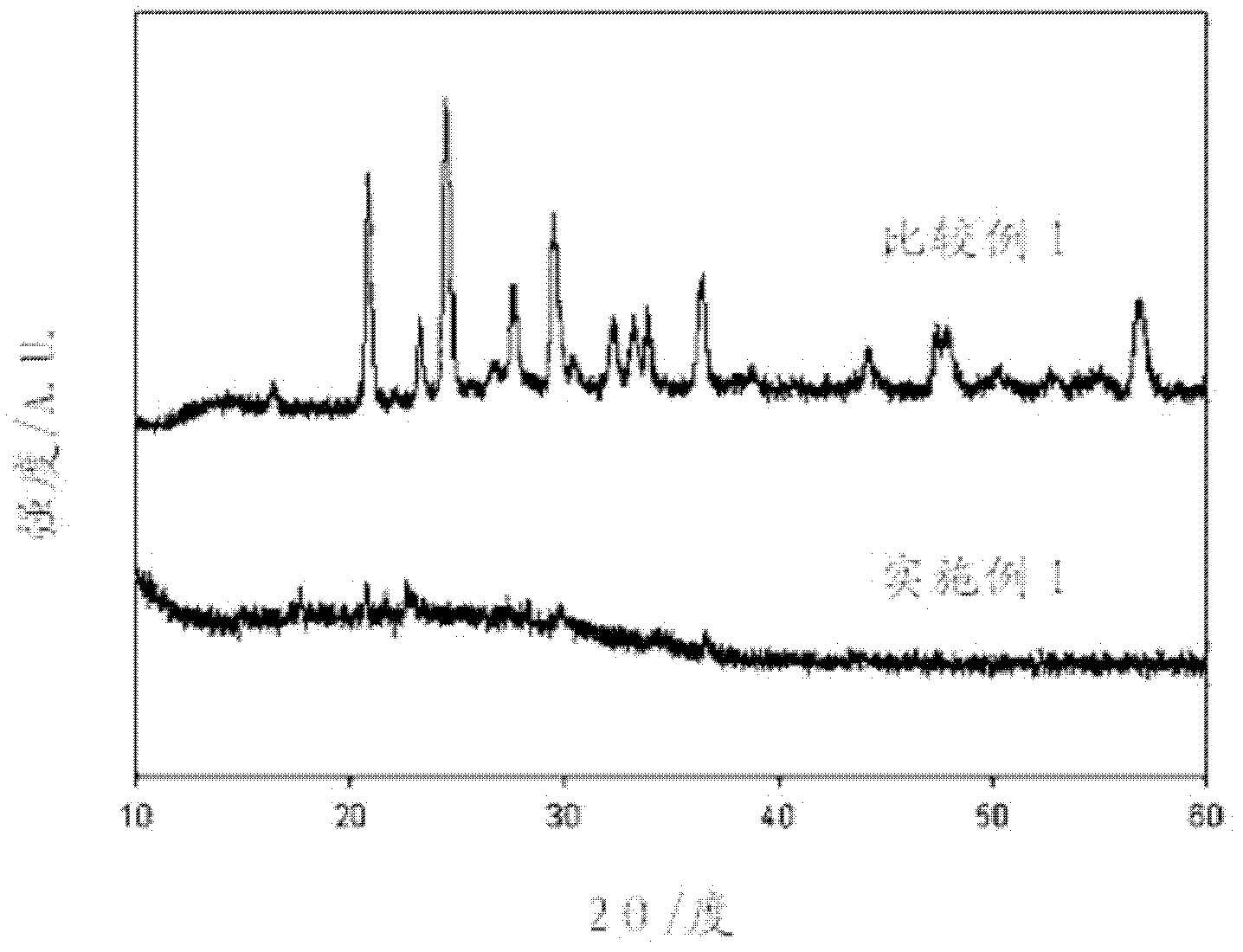

[0083] Embodiment 1 (amorphous Li 3 V 2 (PO 4 ) 3 )

[0084] Lithium hydroxide (LiOH·H 2 O) and ammonium vanadate (NH 3 VO 3 ), stir it while maintaining 70°C to dissolve it completely, and then put it into the dissolved ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) and sucrose (sucrose) solution and fully stirred, then dried at a temperature of 80°C. After extruding and granulating the dried material, it was first heat-treated in an argon atmosphere at 300°C for 6 hours, then pulverized and mixed in an agate mortar, and then granulated again, and heated in an argon atmosphere at 600°C. The heat treatment was carried out in an atmosphere for 12 hours. This is because at a temperature lower than 600° C., vanadium cannot be sufficiently reduced, and thus impurities may remain, and the higher the temperature, the stronger the crystallinity. It was confirmed by elemental analysis that Li:V:P:O=5.0:24.8:22.1:48.1 (weight ratio).

Embodiment 2

[0085] Embodiment 2 (amorphous MoO 2 )

[0086] Prepare 2.5 molar concentration of KBH 4 50ml, its pH is 11-12. and prepare dilute aqueous HCl at pH 1 and 0.25 molar K 2 MoO 4 solution. KBH prepared before 4While the solution was stirring, slowly add K 2 MoO 4 solution, at which time the reduction reaction proceeds to form a solid. This was filtered to recover powder. The powder thus prepared was heat-treated at 300 °C in vacuum to synthesize amorphous MoO 2 . If the heat treatment temperature is 500°C, crystals will be formed, so the heat treatment is performed at a temperature of 500°C or lower. It was confirmed by elemental analysis that Mo:O=74.4:25.6 (weight ratio).

Embodiment 3

[0087] Embodiment 3 (amorphous V 2 o 5 )

[0088] Dissolve crystalline V in distilled water and oxalic acid 2 o 5 Then heat it to boil. At this point, additional hydrochloric acid and distilled water were added, and boiling was continued for 20 minutes. The solution was blue, and if this solution was added to ammonia solution and stirred at room temperature for 30 minutes, a precipitate could be obtained. It was filtered and washed with ethanol to remove impurities. The powder thus obtained was vacuum-dried at 100 °C for one hour to prepare amorphous V 2 o 5 . It was confirmed by elemental analysis that V:O=55.0:45.0 (weight ratio).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com