Degradable sludge-based mulching film and preparation method of degradable sludge-based mulching film

A technology for degrading plastic film and sludge, applied in plant protection covers, agriculture, fertilization devices, etc., can solve problems such as failure to achieve the effect of crop heat preservation and moisture preservation, inability to meet the needs of common crop coverage, and rapid degradation of plastic film, etc. Solve environmental pollution and waste of resources, low prices, and the effect of promoting crop growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

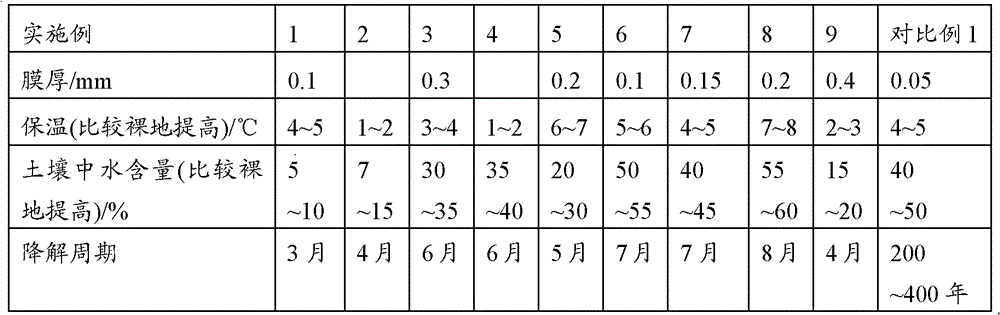

Examples

Embodiment 1

[0053] Get remaining activated sludge 31g (moisture content 80wt%) and citric acid slag 20g to form sludge aggregate after mixing, take by weighing NaOH according to the amount of sludge aggregate 4wt%, be mixed with solution, put after mixing with sludge aggregate Put it into the Erlenmeyer flask, after stirring for 10min at 80°C and 100rpm, add phosphoric acid to adjust to neutrality, then add 15.5g chitosan and 10g starch to the Erlenmeyer flask as a binder, supplement appropriate amount of water, at 70 Continue heating and stirring at 90 rpm for 2 hours, pour the film-forming mixture slurry in the Erlenmeyer flask onto a glass plate, and form a film by casting method. After the film is dry, dilute the silica sol with a solid content of 6.1g 5 times. , sprayed on the surface of the film for waterproof treatment, that is, a waterproof and degradable film is made. Adopt spiral micrometer to measure the thickness of the plastic film, and carry out the film covering test with t...

Embodiment 2

[0055] Get residual activated sludge 120g (moisture content 80wt%) and bagasse 6.3g to form sludge aggregate after mixing, take by weighing ammoniacal liquor according to the amount of sludge aggregate 12wt%, be mixed with solution, put after mixing with sludge aggregate Put it into the Erlenmeyer flask, after soaking at 10°C for 72h, add acetic acid to adjust to neutrality, then add 8g of ethylene glycol as a plasticizer, 20g of sodium alginate and 24.2g of gelatin as a binder into the Erlenmeyer flask, Add 10g of shredded polyester fiber and 5g of heavy calcium carbonate as membrane support materials, add appropriate amount of water, continue heating and stirring at 30°C and 250rpm for 10h, then add 100ml of hot water to dilute, stir evenly, and spray to form a membrane. After it dries, evenly spray on the surface a silicone acrylic emulsion with a solid content of 11.3g diluted 8 times for waterproof treatment, and use the same method as in Example 1 to evaluate the performa...

Embodiment 3

[0057] Get primary sludge 140g (moisture content 80wt%) and bean curd 9g to form sludge aggregate after mixing, take by weighing calcium hydroxide according to the amount of sludge aggregate 8wt%, be mixed with solution, put after mixing with sludge aggregate Put it into the Erlenmeyer flask, after stirring for 10h at 40°C and 40rpm, add humic acid to adjust to neutrality, then add 1.0g mannitol and 1.0g tributyl citrate as plasticizers to the Erlenmeyer flask, 3.5g Polyvinyl alcohol fiber and 3g talcum powder are used as membrane support materials, 12g polyurethane and 47.6g hydroxyethyl fiber are used as binder, add appropriate amount of water, heat to 60°C, continue to stir for 6h under the condition of 200rpm, put the The film-forming mixture slurry is poured on a glass plate, and film is formed by casting method. After the film is dried, dilute the solid content of 1g acrylate and 0.3g silicon acrylic emulsion 5 times, and spray it on the surface of the film for waterproof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com