NGF (nerve growth factor) chitosan microsphere and high-bionic stent slow releasing system and preparation method thereof

A technology of chitosan microspheres and chitosan, which is applied in the field of nerve tissue engineering scaffolds, can solve the problems of inability to release nerve growth factor effectively for a long time, difficulty in nerve regeneration, and large difference, so as to protect biological activity and promote Restoration, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

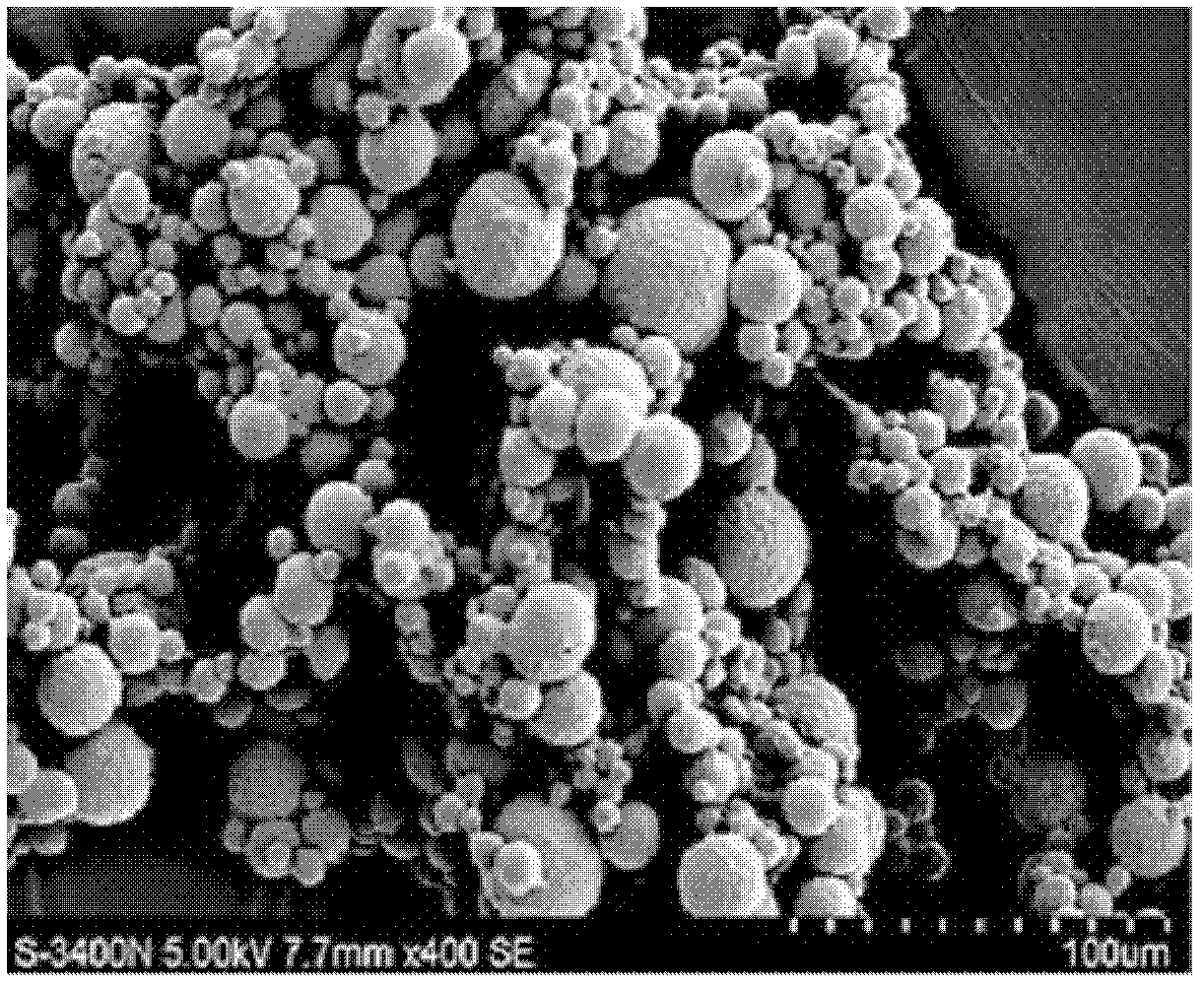

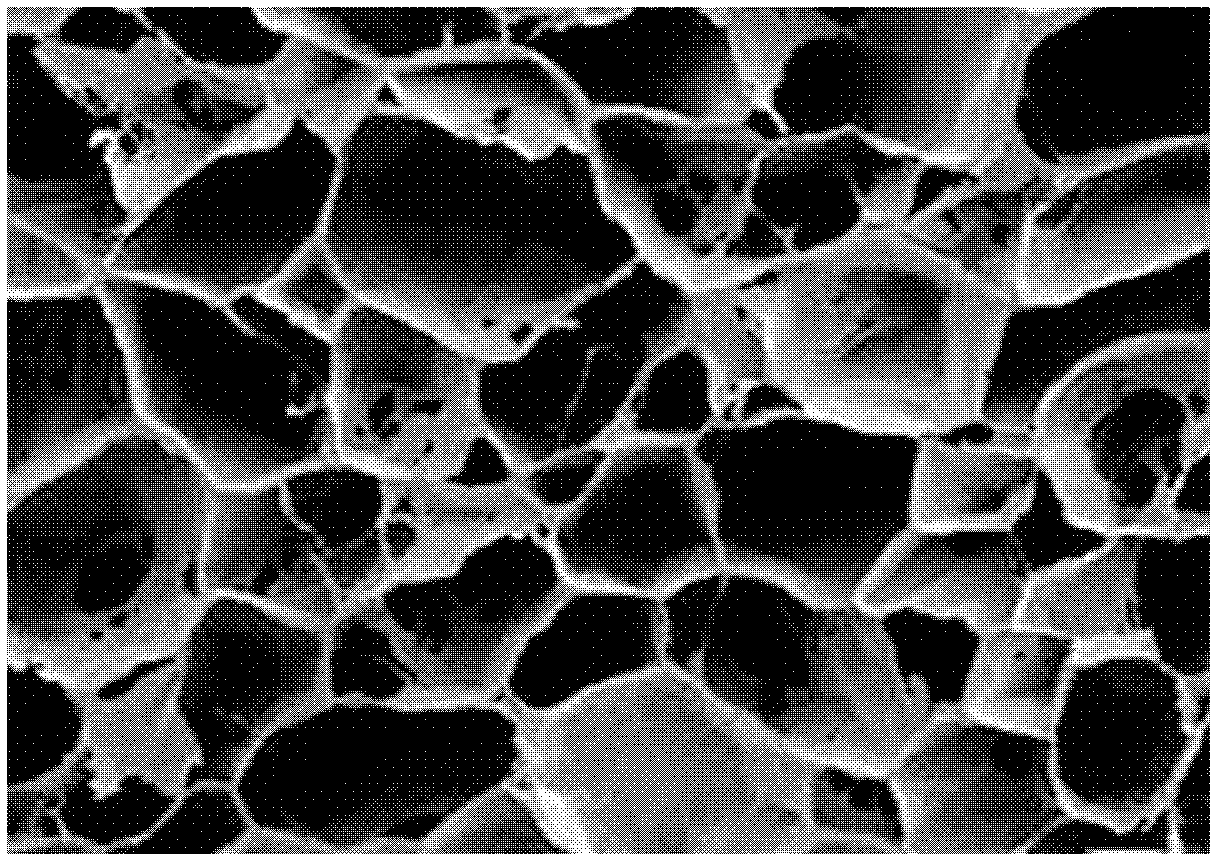

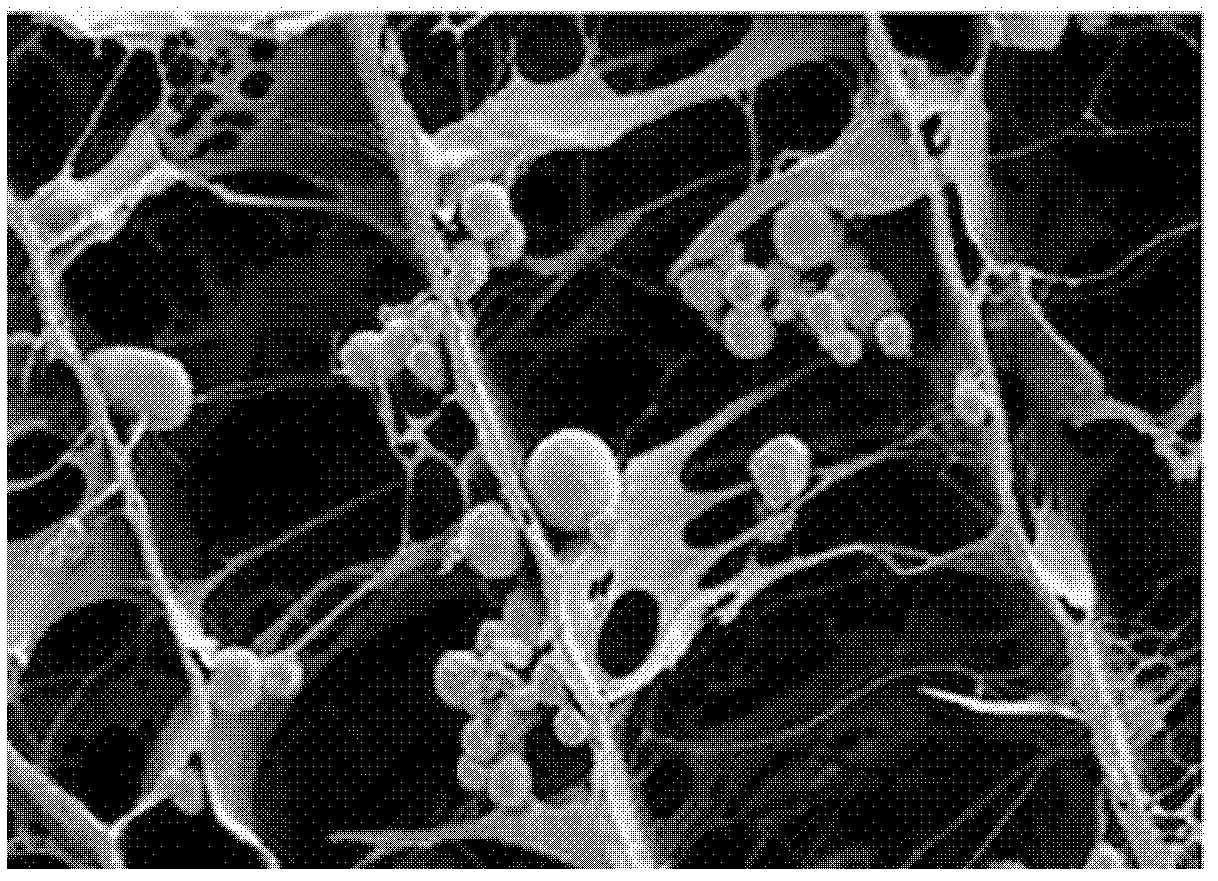

Embodiment 1

[0131] At a low temperature of 2°C, first dissolve 40 μg of nerve growth factor in 10 ml of PBS solution with a pH of 7.2, then pour 800 μg of bovine serum albumin into the solution and completely dissolve to prepare a nerve growth factor solution; 700mg chitosan powder is completely dissolved in 70ml mass-volume concentration of 3mg / ml acetic acid aqueous solution; take 7ml nerve growth factor solution and 35ml chitosan acetic acid solution and fully mix to prepare the water phase; mix 140ml liquid paraffin oil with 2ml surface After the active agent Span80 is measured, it is poured into the three-necked flask in turn, and mechanically stirred for 3 minutes at a stirring speed of 300r / min, so that the liquid paraffin oil and the surfactant Span80 are evenly mixed to prepare an oil phase; at a low temperature of 2°C , add 20ml of the aqueous phase solution dropwise to 100ml of the oil phase, use mechanical stirring for 0.5h, and the stirring speed is 800r / min, to prepare water / ...

Embodiment 2

[0133] At a low temperature of 4°C, first dissolve 60 μg of nerve growth factor in 10 ml of PBS solution with a pH of 7.4, then pour 1500 μg of bovine serum albumin into the solution and completely dissolve to prepare a nerve growth factor solution; 1500mg chitosan powder is completely dissolved in 100ml mass-volume concentration of 3mg / ml acetic acid aqueous solution; fully mix 10ml nerve growth factor solution with 100ml chitosan acetic acid aqueous solution to prepare the water phase; mix 300ml liquid paraffin oil with 4ml surface After the amount of active agent Span80 is taken, it is poured into the three-necked flask in turn, and mechanically stirred for 5 minutes at a stirring speed of 500r / min, so that the liquid paraffin oil and the surfactant Span80 are evenly mixed to prepare an oil phase; at a low temperature of 4°C , add 30ml of water phase solution dropwise to 300ml of oil phase, use mechanical stirring for 1h, stirring speed is 1000r / min, prepare water / oil emulsi...

Embodiment 3

[0135] At a low temperature of 6°C, dissolve 160 μg of nerve growth factor in 20 ml of PBS solution with a pH of 7.6, and then pour 4800 μg of bovine serum albumin into the solution to completely dissolve to prepare a nerve growth factor solution; 4000mg of chitosan powder is completely dissolved in 200ml of acetic acid solution; 10ml of nerve growth factor solution is fully mixed with 150ml of chitosan solution to prepare an aqueous phase; after measuring 240ml of liquid paraffin oil and 3ml of surfactant Span80, Sequentially pour into the three-necked flask, mechanically stir for 7 minutes, and the stirring speed is 700r / min, so that the liquid paraffin oil and the surfactant Span80 are evenly mixed to prepare the oil phase; Add the mixed solution of chitosan and 240ml dropwise into the oil phase, adopt mechanical stirring for 1.5h, and the stirring speed is 1200r / min, to prepare water / oil emulsion; The solution was added dropwise to the water / oil emulsion and mechanically s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross section diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com