Anthraquinone-contained polyphenylene sulfone copolymer and synthetic method thereof

An anthraquinone polyphenylene sulfone and copolymer technology, which is applied in the field of polymer materials and their preparation, can solve the problems of decreased apparent properties, decreased mechanical properties of materials, uneven coloring of resins, etc., and achieves good transparency, good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

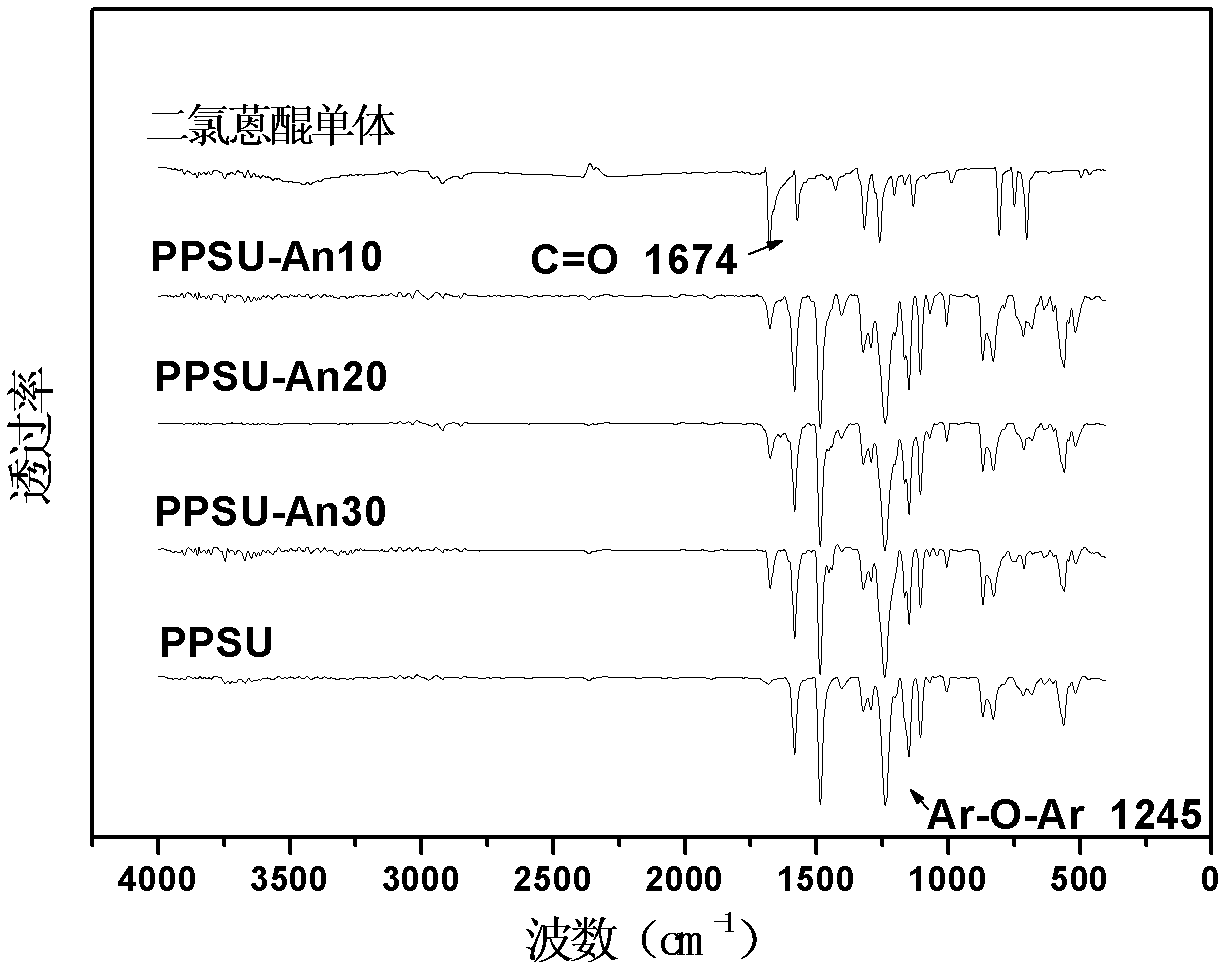

Embodiment 1

[0023] 0.003mol (0.8313g) 1,5-dichloroanthraquinone, 0.027mol (6.8648g) 4,4'-difluorodiphenyl sulfone, 0.03mol (5.5863g) 4,4'-biphenyldiphenol and 0.033 mol (4.5540g) of anhydrous potassium carbonate is added with mechanical stirring, a thermometer, a three-necked flask with a water device and a condenser, and 24.5mL sulfolane (TMS) is a reaction solvent with a solid content of 30%, and 8.2mL toluene is With water agent. Under nitrogen protection, bring water at 130°C for 3 hours, distill off the toluene, continue the heating reaction for 7 hours, and gradually raise the temperature to 160°C. Pour the product into distilled water, filter and crush it, wash it by boiling it for 5 times with distilled water, and wash it by boiling it for 3 times with ethanol, and dry it at 80°C for 12 hours to obtain a yellow polyphenylene sulfone copolymer powder PPSU-An10 with an anthraquinone content of 10%. , with a yield of about 88%.

[0024] The described solid content is that the ratio...

Embodiment 2

[0028] 0.002mol (0.5542g) 1,5-dichloroanthraquinone, 0.008mol (2.034g) 4,4'-difluorodiphenyl sulfone, 0.01mol (1.8621g) 4,4'-diphenol and 0.011 mol (1.5180g) of anhydrous potassium carbonate was added to a three-necked bottle equipped with mechanical stirring, a thermometer, a water device and a condenser, and 15 mL of sulfolane (TMS) was used as a reaction solvent with a solid content of 20%, and 5 mL of toluene was used as a reaction solvent with water. agent. Other steps are the same as in Example 1. A yellow polyphenylene sulfone copolymer PPSU-An20 powder with an anthraquinone content of 20% was obtained with a yield of about 85%.

[0029] The solid content is that the ratio of the mass of the raw material to the mass of the solvent is 20:80.

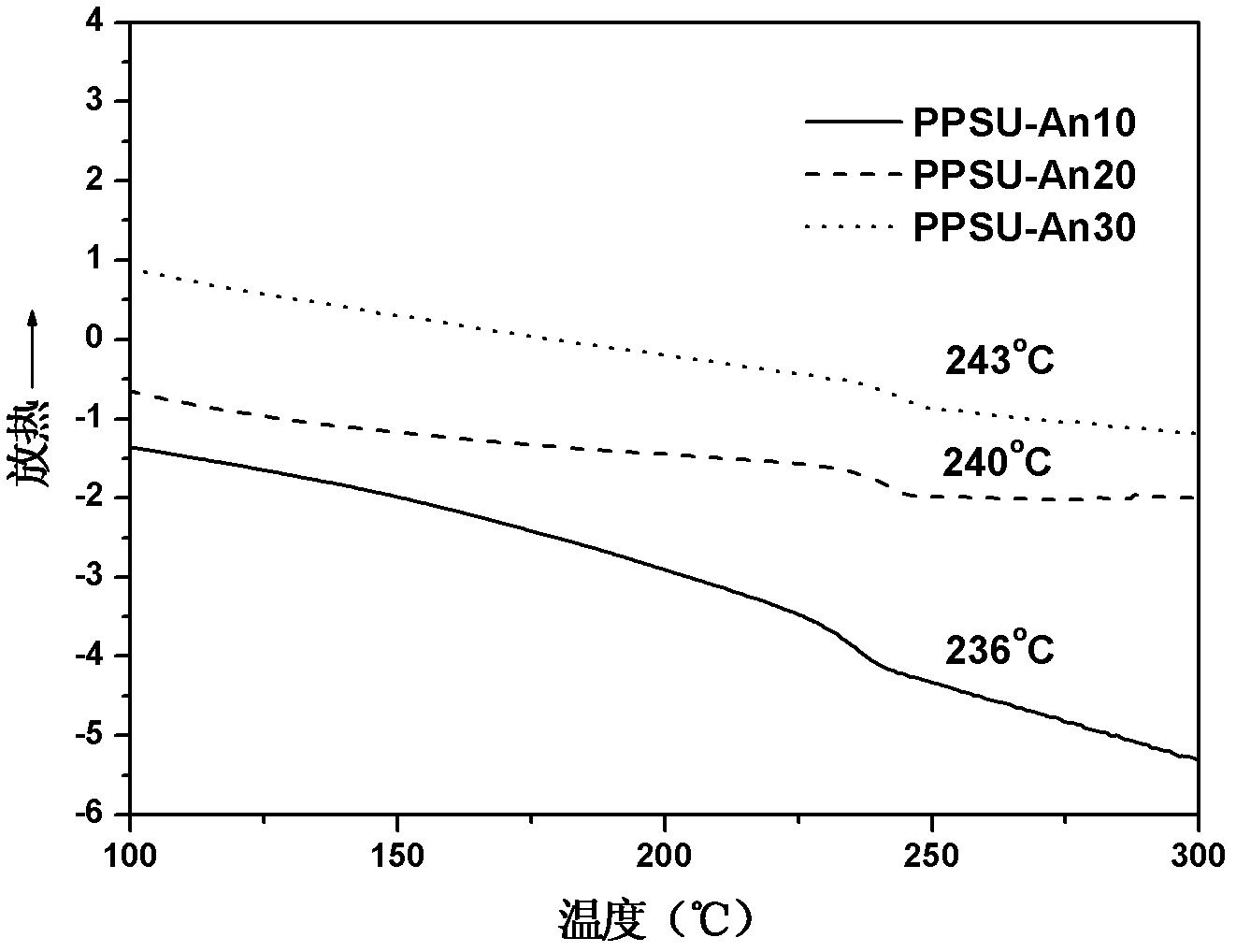

[0030] The glass transition temperature of PPSU-An20 is 240°C.

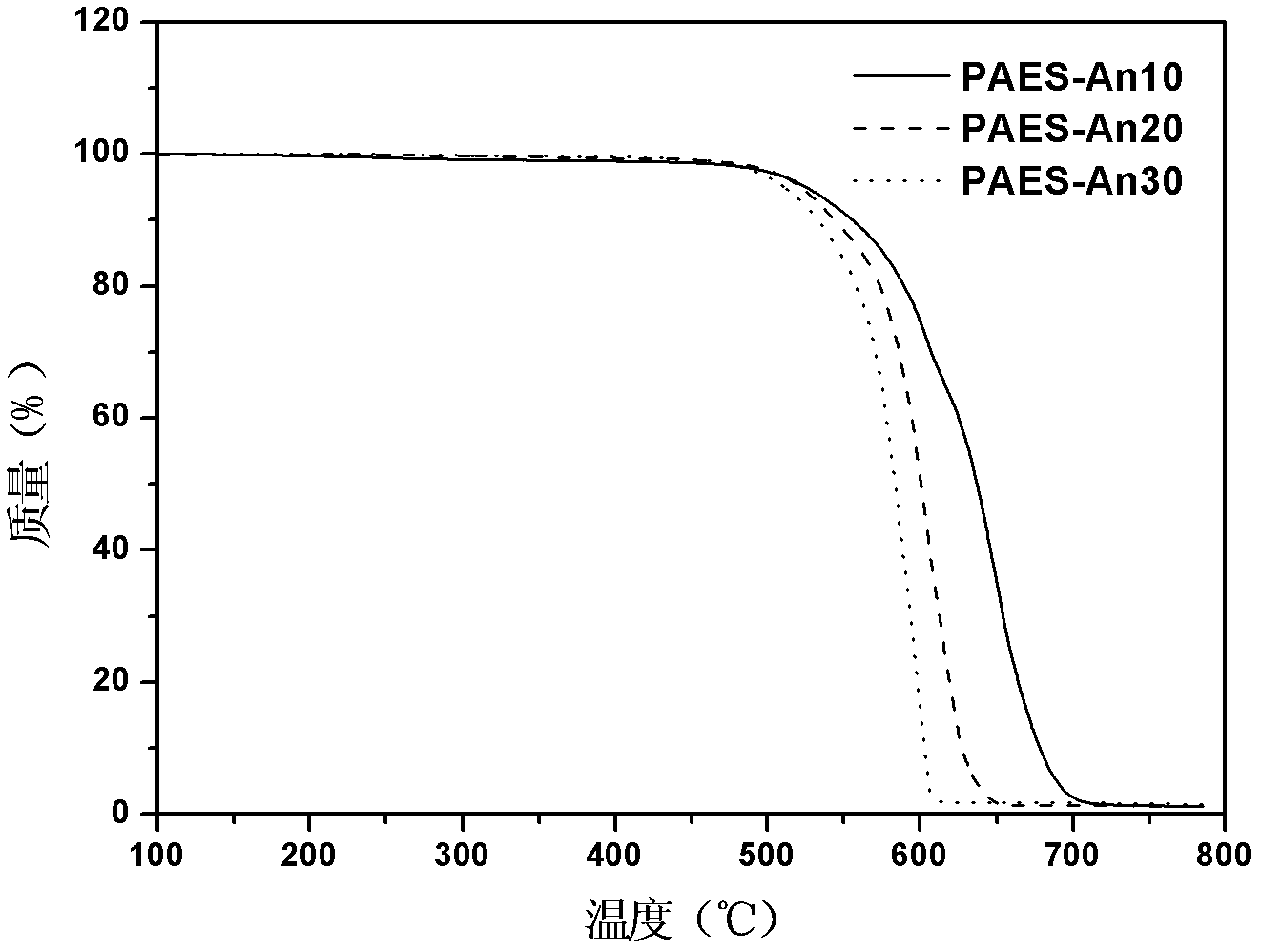

[0031] The 5% thermal weight loss temperature of PPSU-An20 in TGA test under air condition is 520℃.

Embodiment 3

[0033] 0.009mol (2.4939g) 1,5-dichloroanthraquinone, 0.021mol (5.3393g) 4,4'-difluorodiphenyl sulfone, 0.03mol (5.5863g) 4,4'-biphenyldiphenol and 0.033 mol (4.5540g) of anhydrous potassium carbonate was added into a three-necked bottle equipped with mechanical stirring, a thermometer, a water device and a condenser, and 45 mL of sulfolane (TMS) was used as a reaction solvent with a solid content of 20%, and 15 mL of toluene was used as a reaction solvent with water. agent. Other steps are the same as in Example 1. A yellow polyphenylene sulfone copolymer PPSU-An30 powder with an anthraquinone content of 30% was obtained with a yield of about 89%.

[0034] The solid content is that the ratio of the mass of the raw material to the mass of the solvent is 20:80.

[0035] The glass transition temperature of PPSU-An30 is 243°C.

[0036] The 5% thermal weight loss temperature of PPSU-An30 in the TGA test under air condition is 511°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com