Low temperature co-fired ceramic ultra-wideband micro filter

A low-temperature co-fired ceramic and ultra-broadband technology, applied in the field of filters, can solve the problems of unusable applications, large volume and insertion loss, etc., and achieve the effects of light weight, high reliability and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

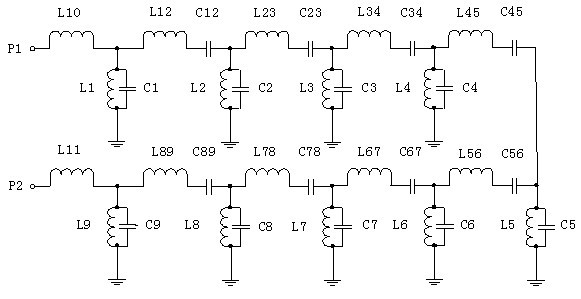

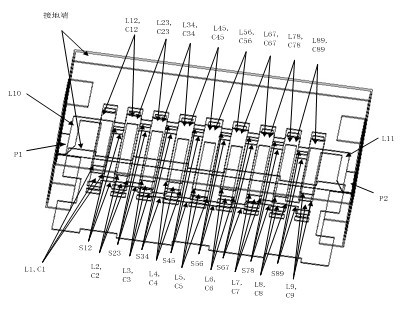

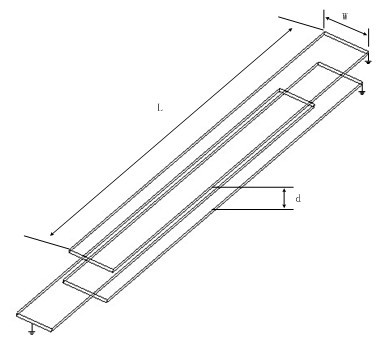

[0012] combine figure 1 , figure 2 , image 3 with Figure 4 , the present invention is a low-temperature co-fired ceramic ultra-wideband micro-filter, which includes a surface-mounted 50-ohm impedance input port P1, an input inductance L10, a first-stage parallel resonant unit L1, C1, and a first-stage inter-coupling Circuit L12, C12, second stage parallel resonant unit L2, C2, second interstage coupling circuit L23, C23, third stage parallel resonant unit L3, C3, third interstage coupling circuit L34, C34, fourth stage parallel resonant Unit L4, C4, fourth interstage coupling circuit L45, C45, fifth stage parallel resonance unit L5, C5, fifth interstage coupling circuit L56, C56, sixth stage parallel resonance unit L6, C6, sixth interstage coupling Circuit L67, C67, seventh stage parallel resonant unit L7, C7, seventh interstage coupling circuit L78, C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com