Preparation method of composite carbon base solid acid catalyst

A technology of solid acid catalyst and composite carbon, which is applied in the preparation of organic compounds, preparation of carboxylic acid esters, chemical instruments and methods, etc., can solve the problems of expensive raw material sources, underdeveloped pore size, and difficulty in regulation, and achieve mechanical strength and stability High catalytic activity, improved acidity, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Preparation of composite resin:

[0019] At room temperature, take 4g of sucrose with a particle size of about 190μm, add it to a beaker filled with 40g of sodium humate solution with a mass concentration of 10%, and stir it magnetically for about 30 minutes. , a thermometer, a reflux condensing tube, and a three-necked flask of a water separator, then add 2.3ml of formalin as a crosslinking agent and 2.2g of p-toluenesulfonic acid as a catalyst; 2 Stir and heat to reflux. When the heating temperature reaches 80°C, keep the temperature constant for 12 hours; then vacuum dehydrate at 0.08MPa and dry for 4 hours to obtain a black block composite resin;

[0020] (2) carbonization

[0021] Grind the above-mentioned massive composite resin to about 200 meshes, and place it in a carbonization furnace under N 2 Under protection, after carbonization at 450°C for 8h, cool to room temperature;

[0022] (3) Washing, suction filtration and drying:

[0023] Add the above-men...

Embodiment 2-7

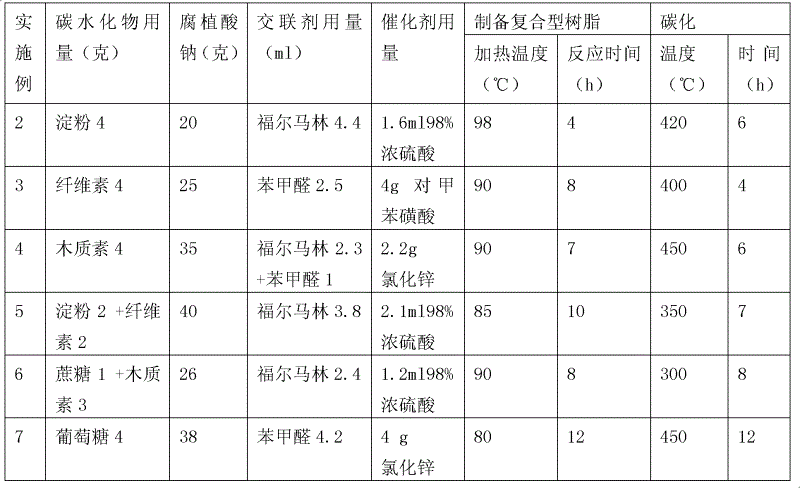

[0027] On the basis of the process step of above-mentioned embodiment 1, change carbohydrate, cross-linking agent, catalyst and process technology condition, specifically see the following table:

[0028]

[0029] In the above examples, the acidity (mmol / g) of the obtained sulfonated solid acid is between 1.52-1.86.

Embodiment 8-12

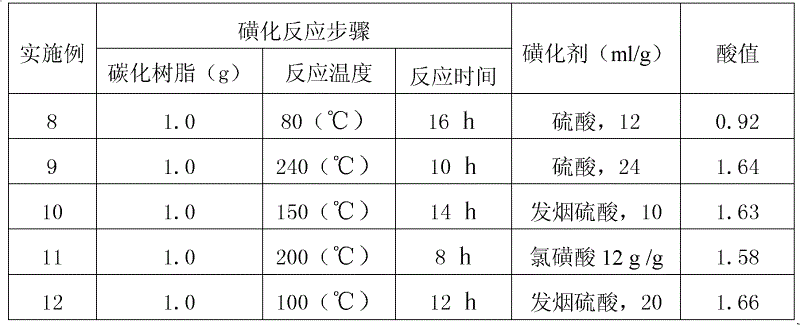

[0031] On the basis of the process steps of any of the above-mentioned embodiments, change the process conditions described in the table below in the sulfonation reaction step, the results are shown in the table below:

[0032]

[0033] In the above-mentioned embodiments, the drying time and temperature are determined at 110-120° C. for 2-6 hours according to the specific conditions of the materials, and the purpose is to dry the materials.

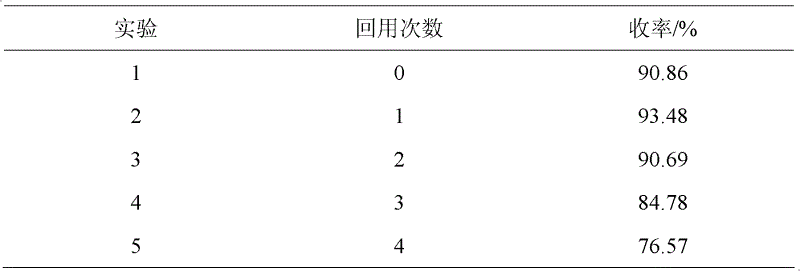

[0034] The composite carbon-based solid acid catalyst obtained in the above examples was used in the catalytic esterification reaction and the catalytic condensation reaction respectively, and the process is shown in the following examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com