Preparation method for Fe3O4/SiO2 nanometer particle containing multiple magnetism cores

A nanoparticle, fe3o4 technology, applied in nanotechnology, nanomagnetism, nanotechnology, etc., can solve the problems of weak response to external magnetic field and small number of magnetic cores, and achieve easy operation, uniform particle size and excellent magnetic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

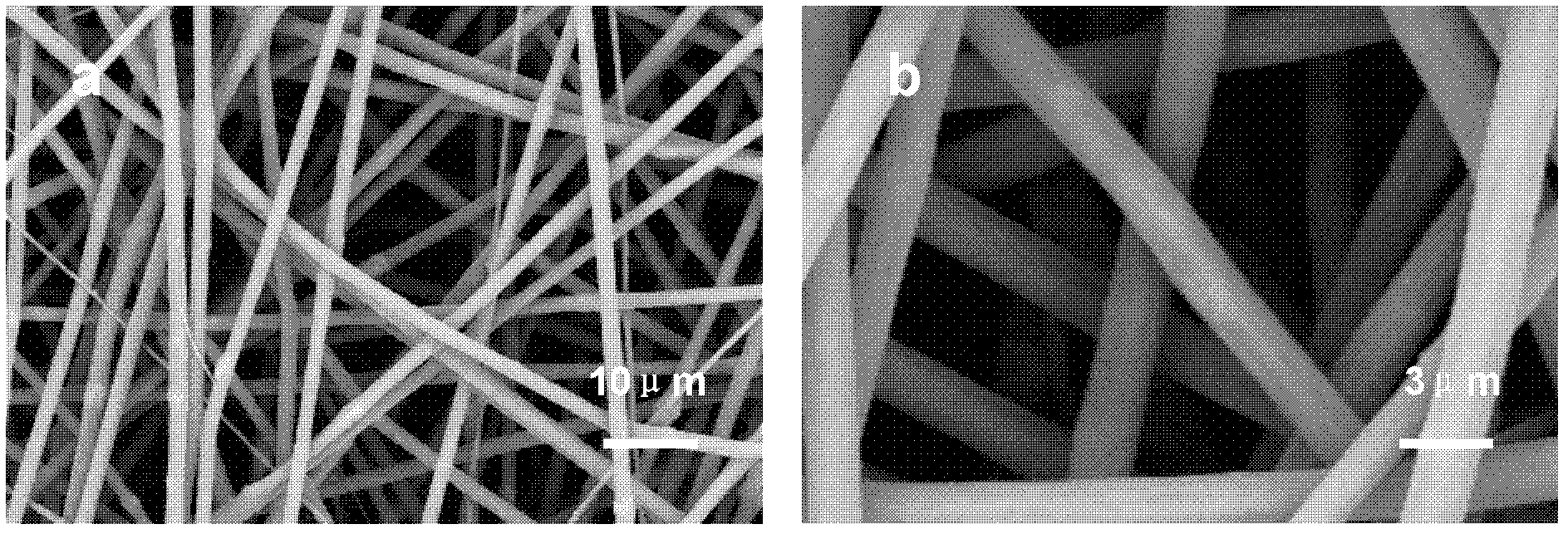

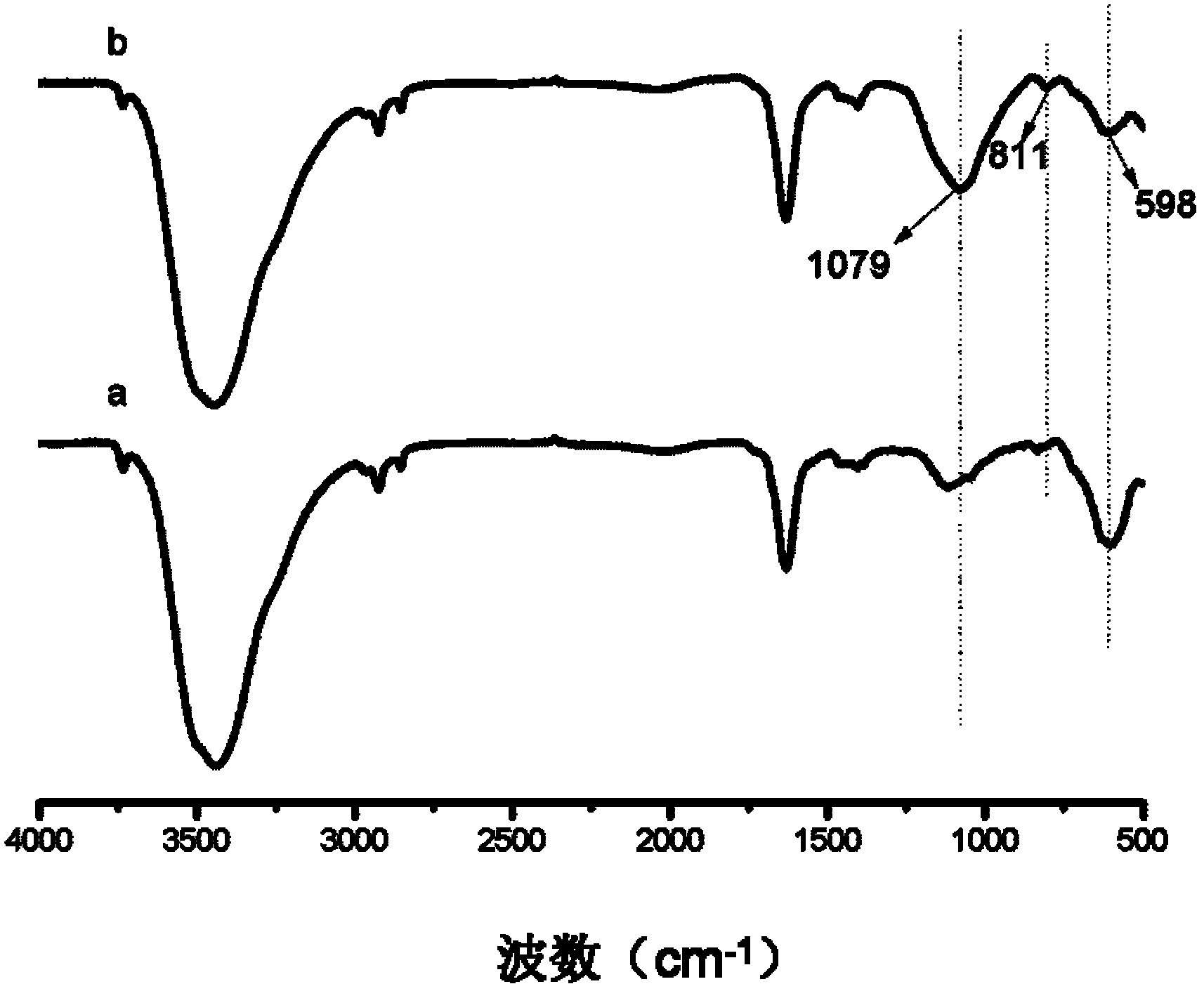

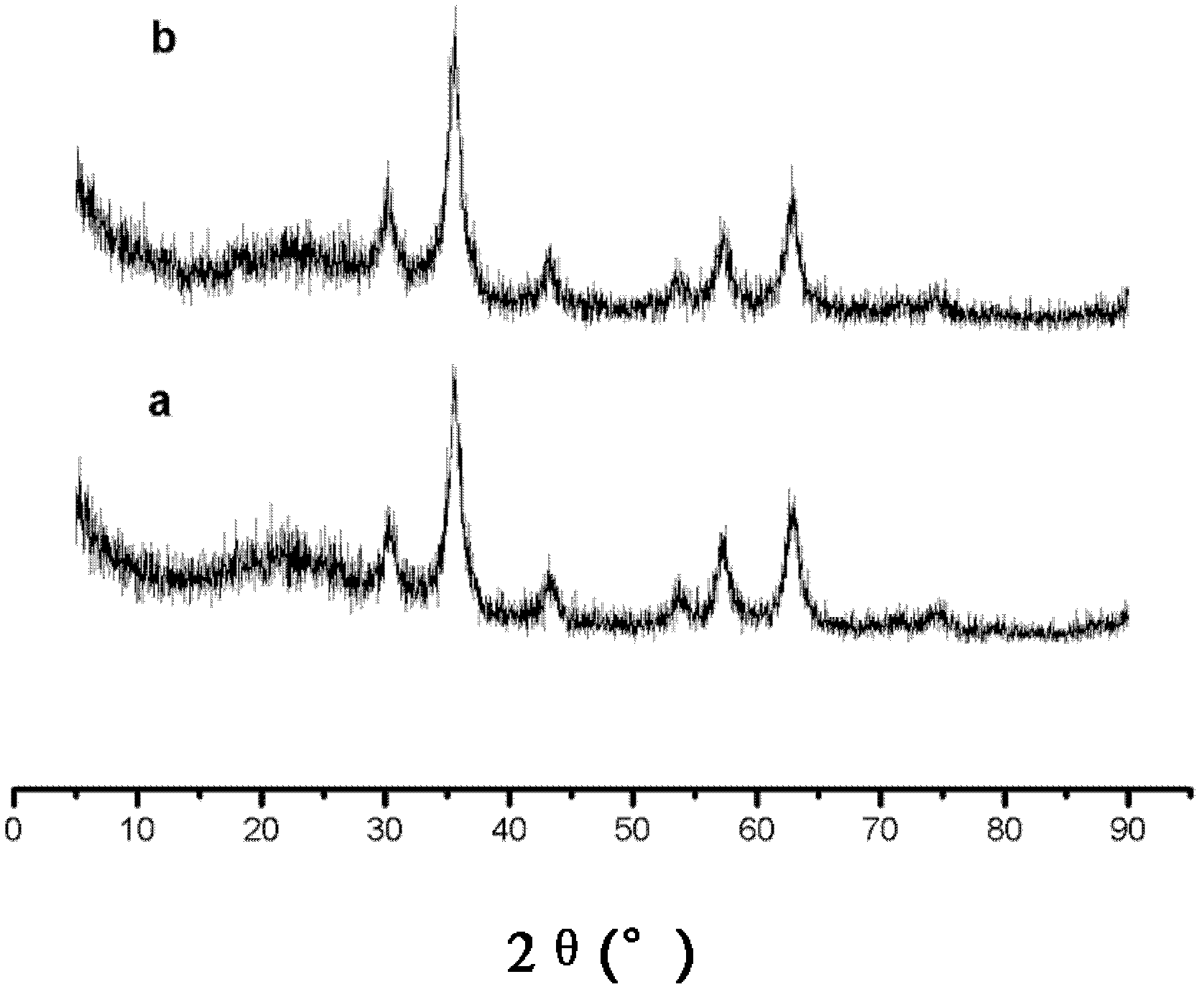

[0031] Prepare the spinning solution according to the following steps: 0.2g Fe 3 o 4 , 0.2g CTAB and 1.0mL TEOS were dissolved in an Erlenmeyer flask filled with 10mL isopropanol at room temperature; then ultrasonically treated for 15min; then 1.0g PVP K90 fine powder was added to it, and a uniform brown spinning was obtained after magnetic stirring for 24 hours. silk liquid. After the solution is prepared, a certain amount of PVP spinning liquid is extracted with a syringe, fixed on the electrospinning device, and various spinning parameters are adjusted for electrospinning.

[0032] The nanofibers obtained by electrospinning were peeled off from the aluminum foil, put into a 250ml three-necked flask, and then an aqueous ethanol solution (PH=9.0) with an ethanol volume concentration of 80% was added to it and heated at 40°C. , vigorously stirred (100r / min) for 24h, that is, Fe containing multiple magnetic cores 3 o 4 / SiO 2 nanoparticles.

[0033] The electrospun nanofib...

Embodiment 2

[0035] Prepare the spinning solution according to the following steps: 0.10g Fe 3 o 4 , 0.2g CTAB and 0.8mL TEOS were dissolved in an Erlenmeyer flask filled with 10mL isopropanol at room temperature; then ultrasonically treated for 20min; silk liquid. After the solution is prepared, a certain amount of PVP spinning liquid is extracted with a syringe, fixed on the electrospinning device, and various spinning parameters are adjusted for electrospinning.

[0036] During electrospinning, the size of the syringe is 5mL, the inner diameter of the needle is about 1mm, and the receiving screen is grounded with aluminum foil; the ejection flow rate is 2-3.5mL / h, the voltage is 10-13kv, and the distance between the needle and the receiving screen is 15-18cm.

[0037] The nanofibers obtained by electrospinning were peeled off from the aluminum foil, put into a 250ml three-necked flask, and then an aqueous ethanol solution (PH=8.0) with an ethanol volume concentration of 80% was added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com