Method for synthesizing polymerized phenyl phosphonate by performing solid-liquid two-phase reaction

A phenylphosphonate and polymeric technology, which is applied in the field of solid-liquid two-phase reaction synthesis of polymeric phenylphosphonate, can solve the problems of poor heat resistance, high volatility, and decreased physical properties, and achieve thermal stability Good, high degree of polymerization, simple reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

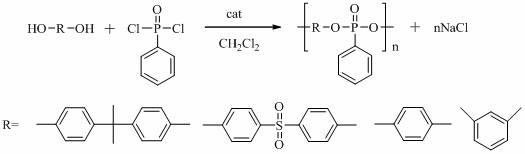

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 170 g of NaOH in 4L of water to prepare a NaOH solution, add 456 g of bisphenol A into the reaction vessel, slowly pour all the NaOH solution into the reaction vessel, and stir at room temperature until completely dissolved under nitrogen protection to form a Salt. The water was distilled off under reduced pressure, and after vacuum drying, 530 g of bisphenol A disodium salt was obtained as a white solid.

Embodiment 2

[0030] Dissolve 170 g of NaOH in 4 L of water to prepare NaOH solution, add 500 g of bisphenol S into the reaction container bottle, slowly pour all the NaOH solution into the reaction container, and stir at room temperature until completely dissolved under nitrogen protection ,A salt. Water was distilled off under reduced pressure, and 560 g of bisphenol S disodium salt was obtained after vacuum drying.

Embodiment 3

[0032] 500 g of bisphenol A disodium salt is dropped into the reaction vessel, 70 g of tetrahexyl ammonium chloride is weighed and put into the reaction vessel, 360 g of phenylphosphonic dichloride is weighed and dissolved in 12 L of methylene chloride, and the benzene The dichloromethane solution of phosphonodichloride was poured into the reaction vessel, and the temperature was raised to reflux for 2 h. The reaction mixture was washed with water for 3-4 times, the organic phase was separated, and the organic phase was concentrated to about 1.2 L, and then 25 L of petroleum ether was poured into the organic phase, left to stand, and the liquid was decanted, and the product was precipitated at the bottom. The product at the bottom was dried at 70°C, agglomerated into a solid after cooling, and pulverized.

[0033] The product was a white waxy solid with a mass of 601 g and a yield of 93.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com