Photochemical degradation agent for treating paper making paper making black liquor and preparation method thereof

A papermaking black liquor and photochemical technology, applied in chemical instruments and methods, physical/chemical process catalysts, energy and wastewater treatment, etc., can solve the problems of high cost and high energy consumption, and achieve the effect of simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

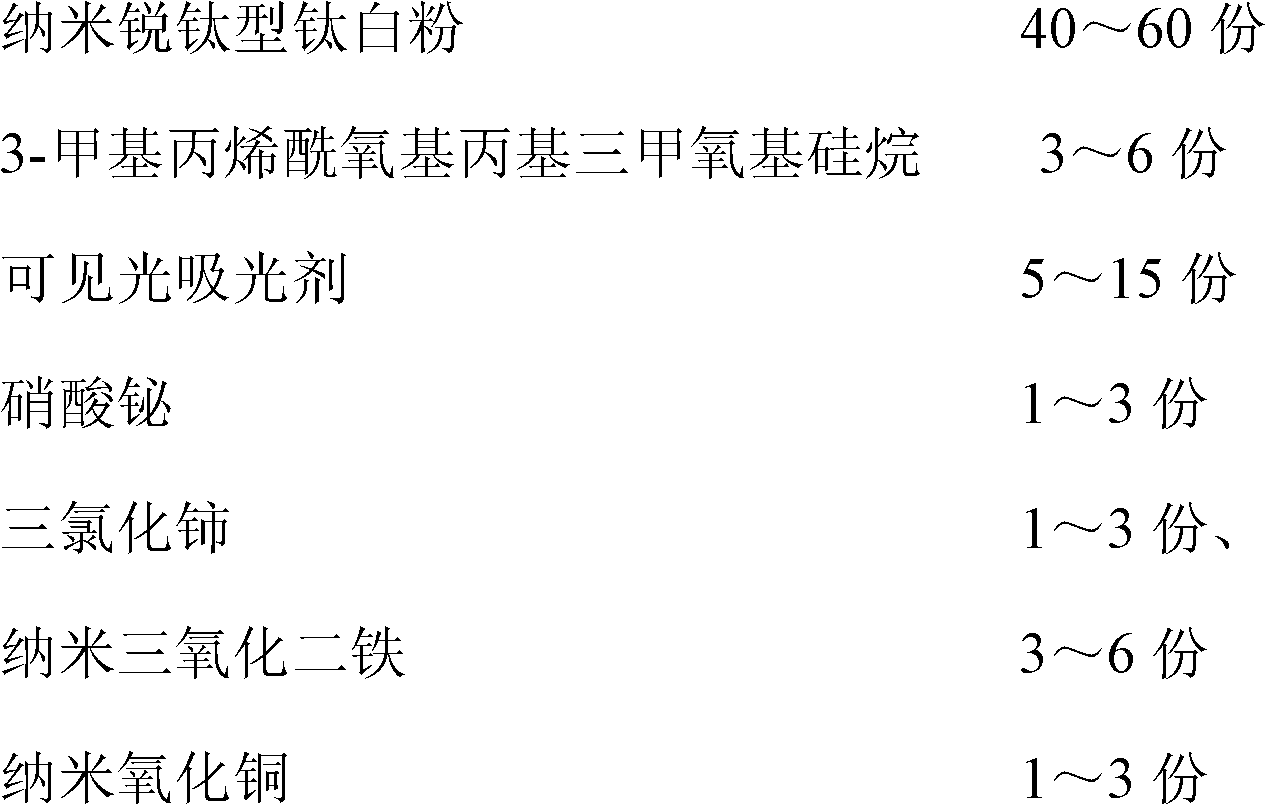

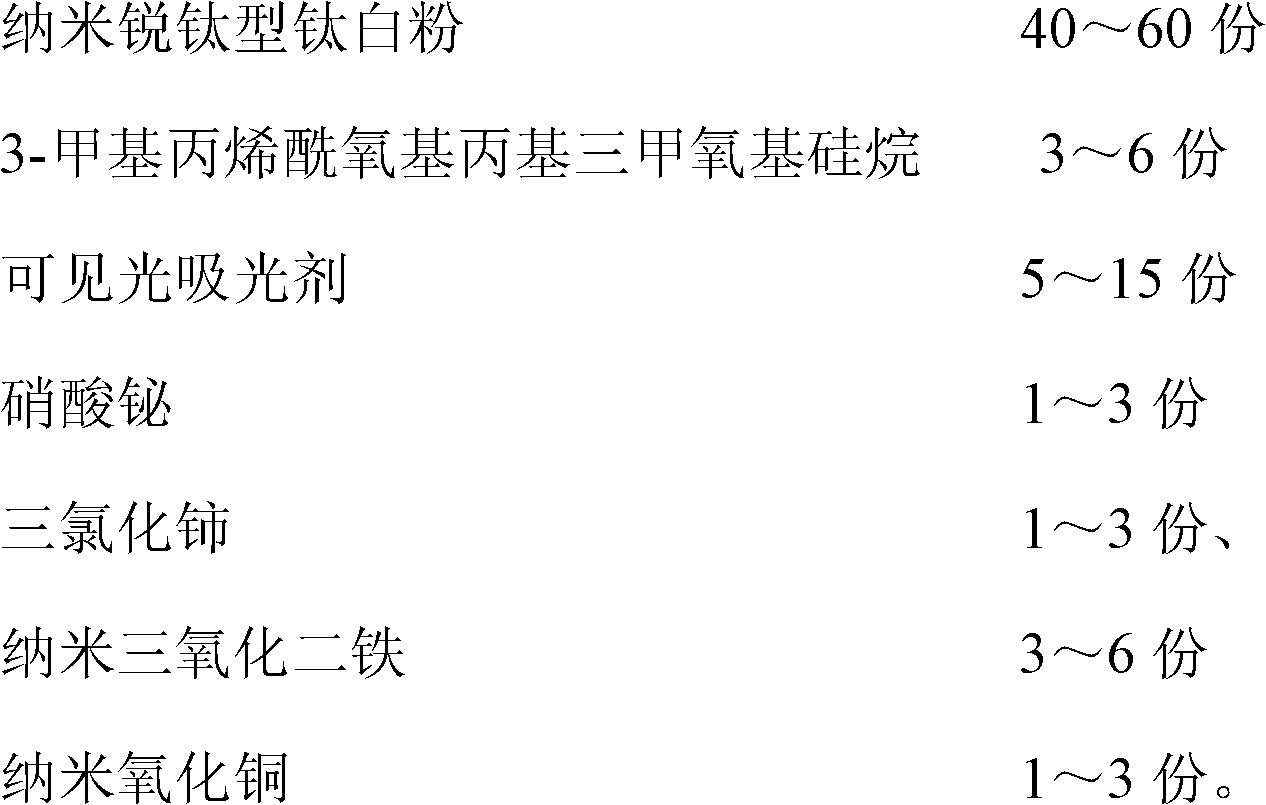

[0036] formula:

[0037] 40 parts of nano-anatase titanium dioxide, 3 parts of 3-methacryloxypropyltrimethoxysilane, 0.3 parts of cobalt acetylacetonate, 5 parts of visible light absorbing agent, 1 part of bismuth nitrate, 0.5 parts of cerium trichloride, 0.1 part of sodium rhodium chloride, 3 parts of nano-ferric oxide, and 1 part of nano-copper oxide.

[0038] The visible light absorber is composed of the following components in parts by weight:

[0039] 12 parts of methanol;

[0040] 85 parts of ethanol

[0041] 0.15 parts of 1,1'-diethyl-3,3'-bis(γ-sulfopropyl)5,5'-bistrifluoromethylimidazocyanine sodium salt

[0042] 0.15 parts of 3,3-diethyl-9-methylthiocarbocyanine iodide salt,

[0043] Mix all the above items and heat to 40°C to dissolve to obtain a visible light absorber;

[0044] Preparation:

[0045] Raise the temperature of nano-anatase titanium dioxide to make the temperature of titanium dioxide powder 85°C, then spray 3-methacryloxypropyltrimethoxysilane, s...

Embodiment 2

[0047] formula:

[0048] 42 parts of nano-anatase titanium dioxide, 4 parts of 3-methacryloxypropyltrimethoxysilane, 0.4 parts of cobalt acetylacetonate, 7 parts of visible light absorbing agent, 0.9 parts of bismuth nitrate, 0.6 parts of cerium trichloride, 0.15 parts of sodium rhodium chloride, 3 parts of nano-ferric oxide, and 1.5 parts of nano-copper oxide.

[0049] The visible light absorber is composed of the following components in parts by weight:

[0050] 8 parts of methanol;

[0051] Ethanol 95 parts

[0052] 0.15 parts of 1,1'-diethyl-3,3'-bis(γ-sulfopropyl)5,5'-bistrifluoromethylimidazocyanine sodium salt

[0053] 0.05 parts of 3,3-diethyl-9-methylthiocarbocyanine iodide salt,

[0054] Mix all the above items and heat to 40°C to dissolve to obtain a visible light absorber;

[0055] Preparation:

[0056]Raise the temperature of the nano-anatase titanium dioxide to make the titanium dioxide powder temperature 90°C, then spray 3-methacryloxypropyltrimethoxysilan...

Embodiment 3

[0058] formula:

[0059] 44 parts of nano anatase titanium dioxide, 5 parts of 3-methacryloxypropyltrimethoxysilane, 0.5 parts of cobalt acetylacetonate, 9 parts of visible light absorbing agent, 0.6 parts of bismuth nitrate, 0.7 parts of cerium trichloride, 0.2 parts of sodium rhodium chloride, 2.5 parts of nano-ferric oxide, and 2 parts of nano-copper oxide.

[0060] Visible light absorber is the same as embodiment 1.

[0061] Preparation:

[0062] Raise the temperature of nano-anatase titanium dioxide to make the temperature of titanium dioxide powder 85°C, then spray 3-methacryloxypropyltrimethoxysilane, stir for 60 minutes, add cobalt acetylacetonate solution, and stir for 20 minutes After adding the visible light absorbing agent, continue to stir. After an interval of 20 minutes, add bismuth nitrate solution. Iron, add nano-sized copper oxide after an interval of 10 minutes, and stir for 60 minutes to evaporate the solvent in the powder to obtain the product

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com