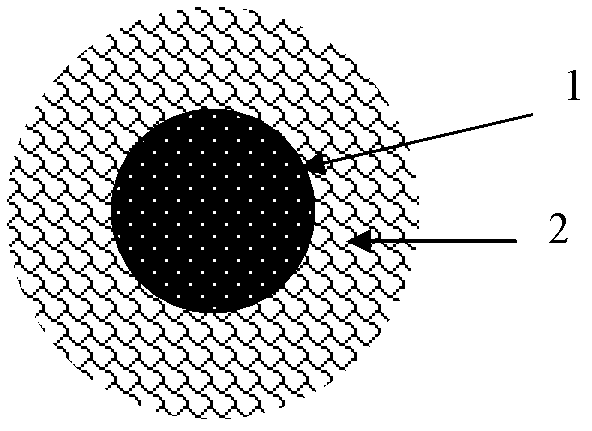

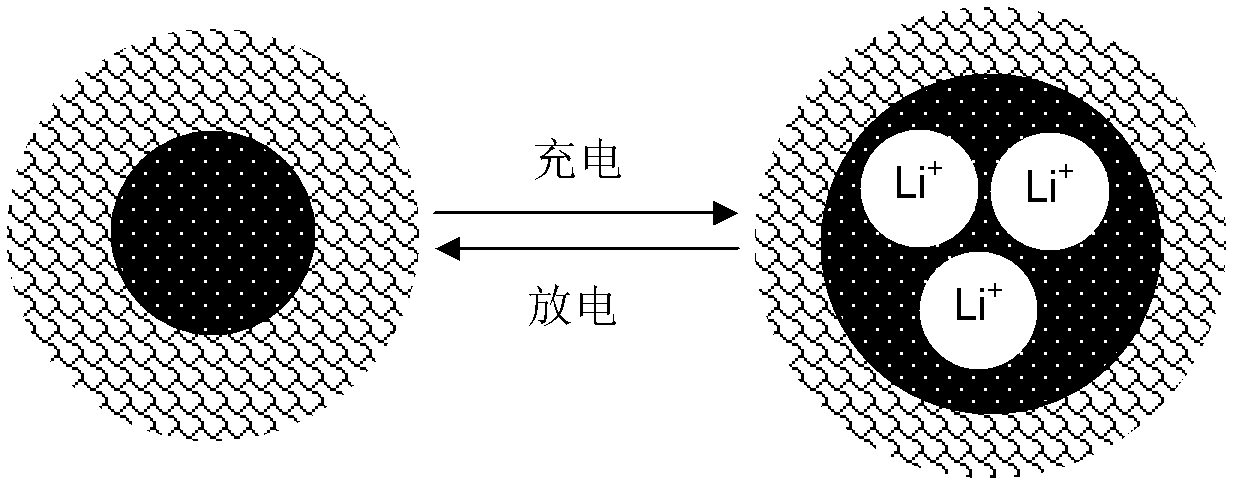

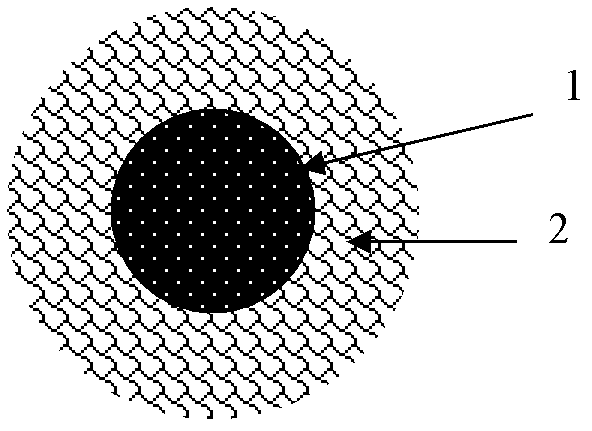

Lithium ion battery and preparation method thereof

A lithium-ion battery and battery negative electrode technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problems of affecting battery cycle stability, weak binding force, and uneven carbon coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) dissolving the organic precursor polyacrylonitrile in tetrahydrofuran to form a homogeneous solution with a mass concentration of 10%;

[0037] (2) adding a certain amount of silicon into the above solution, and mixing the silicon with the solution evenly to form a spinning stock solution; the amount of silicon added is 5wt.% of the organic precursor;

[0038] (3) Prepare the organic fiber felt containing silicon by the above spinning stock solution by electrospinning; wherein the spinning stock solution propulsion speed is 1mL / h, the voltage is 15KV, and the receiving distance is 10cm;

[0039] (4) Carbonize the organic fiber felt in an argon atmosphere, and heat up at a heating rate of 10°C / min until the temperature of the furnace body is 900°C; after 4 hours of heat preservation, all the organic fibers are pyrolyzed and carbonized to form carbon fibers ;

[0040] (5) Pulverizing the material obtained in the previous step to obtain the battery negative electrode ...

Embodiment 2

[0044] (1) dissolving the organic precursor polyacrylonitrile in dimethyl sulfoxide to form a homogeneous solution with a mass concentration of 30%;

[0045] (2) adding a certain amount of silicon monoxide into the above solution, and mixing the silicon monoxide with the solution evenly to form a spinning stock solution; the amount of silicon monoxide added is 5wt.% of the organic precursor;

[0046] (3) Prepare the organic fiber mat containing silicon monoxide by electrospinning the above spinning stock solution; wherein the spinning stock solution advance speed is 1.5mL / h, the voltage is 25KV, and the receiving distance is 15cm;

[0047] (4) Carbonize the organic fiber mat in a mixed gas of 5% hydrogen and 95% argon, and heat up at a heating rate of 5°C / min until the temperature of the furnace body is 900°C; All organic fibers are pyrolyzed and carbonized to form carbon fibers;

[0048] (5) pulverizing the material obtained in the previous step to obtain the negative electr...

Embodiment 3

[0052] (1) dissolving the organic precursor polyacrylonitrile in dimethylamide to form a homogeneous solution with a mass concentration of 15%;

[0053] (2) adding a certain amount of silicon dioxide to the above solution, and mixing the silicon dioxide with the solution evenly to form a spinning stock solution; the amount of silicon dioxide added is 10wt.% of the organic precursor;

[0054] (3) Prepare the organic fiber felt containing silicon dioxide by electrospinning the above spinning stock solution; wherein the spinning stock solution propulsion speed is 1.2mL / h, the voltage is 18KV, and the receiving distance is 11.5cm;

[0055] (4) Carbonize the organic fiber mat in an argon atmosphere, and heat up at a heating rate of 5°C until the temperature of the furnace body is 800°C; after 4 hours of heat preservation, all the organic fibers are pyrolyzed and carbonized to form carbon fibers;

[0056] (5) pulverizing the material obtained in the previous step to obtain the negativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com