Method for preparing graphene modified by silane coupling agent

A technology of silane coupling agent and graphene, which is applied in the field of preparation of silane coupling agent modified graphene, to achieve the effects of fast hydrolysis, easy process control and low reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Take 0.1 g of graphite oxide, disperse it into 100 mL of DMF, pour it into a 250 mL three-necked flask, add 0.1 g of γ-aminopropyltriethoxysilane, and react under mechanical stirring (800 RPM) at room temperature for 12 hours, then filter with suction. After washing with DMF several times, graphite oxide modified with γ-aminopropyltriethoxysilane was obtained. Take 0.1 g of γ-aminopropyltriethoxysilane-modified graphite oxide, transfer it to a 250 mL three-neck flask, add 0.2 g of hydrazine hydrate and 100 mL of DMF, heat to 80 °C, and react for 12 h under mechanical stirring (200 RPM) , cooled to room temperature, suction filtered and washed with DMF several times, and dried in vacuum at 40°C to obtain γ-aminopropyltriethoxysilane-modified graphene.

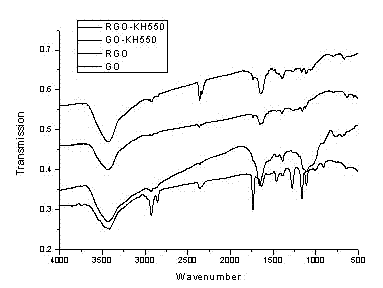

[0036] Take a sample and test the product. figure 1 is a transmission electron micrograph of graphite oxide modified with γ-aminopropyltriethoxysilane; figure 2 is a transmission electron micrograph of graphene modified...

Embodiment 2

[0038] The preparation method is the same as in Example 1, wherein the γ-aminopropyltriethoxysilane is replaced by a siloxane conforming to the following general formula: R-Si(OR 1 ) 3 or R R 2 -Si(OR 1 ) 2 , where R is a hydrogen atom, methyl, ethyl, propyl, butyl, phenyl, cyclohexyl, vinyl, propenyl, aminoethylaminopropyl, mercaptopropyl, anilinomethyl and other organic groups , R 1 is methyl or ethyl, R 2 is a hydrogen atom, methyl or ethyl.

[0039] Take a sample and test the product. Figure 4 to Figure 7 They are graphite oxide, graphite oxide modified by γ-aminopropyltriethoxysilane, graphite oxide modified by N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, and N-(β-ammonia The XPS spectrum of graphene modified by ethyl)-γ-aminopropyltrimethoxysilane, it can be seen from the figure that there are more characteristic double peaks of silicon in the last three figures, indicating that the silane coupling agent molecule has been successfully modified to on the surf...

Embodiment 3

[0041] Take 0.1 g of graphite oxide, disperse it into 150 mL of methanol, pour it into a 250 mL three-necked flask, add 0.01 g of γ-aminopropyltriethoxysilane, react under mechanical stirring (1000 RPM) at 0 ℃ for 72 hours, and filter with suction , washed with methanol several times to obtain γ-aminopropyltriethoxysilane-modified graphite oxide. Take 0.1 g of γ-aminopropyltriethoxysilane-modified graphite oxide, transfer it to a 250 mL three-necked flask, and add 0.05 g of sodium borohydride and 150 mL of methanol. Under mechanical stirring (1000RPM), react at room temperature for 24 h, filter with suction and wash with methanol several times, and dry at room temperature to obtain γ-aminopropyltriethoxysilane-modified graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com