Eu3+ activated rear earth silicon phosphate fluorescent powder and preparing method and application thereof

A technology of silicon phosphate and fluorescent powder, which is applied in the field of rare earth luminescent materials, can solve the problems of low excitation efficiency and poor stability, and achieve the effects of easy product, simple preparation process, and no waste water and waste gas discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Press La 9.35 Eu 1.65 P 3 SiO 26 Weigh the molar ratio of each element in: europium oxide 0.726g, lanthanum oxide 3.808g, ammonium dihydrogen phosphate 0.8627g, silicon dioxide 0.153g; grind and mix all the raw materials weighed well in an agate mortar; select Air atmosphere, pre-fire the homogeneously mixed raw materials in a muffle furnace at 600°C for 7 hours, cool to room temperature; grind and mix evenly, sinter in a muffle furnace at 900°C for 5 hours, cool to room temperature and grind Mix evenly, sinter in a muffle furnace at 1350°C for 14 hours, and cool to room temperature to obtain La 9.35 Eu 1.65 P 3 SiO 26 red phosphor.

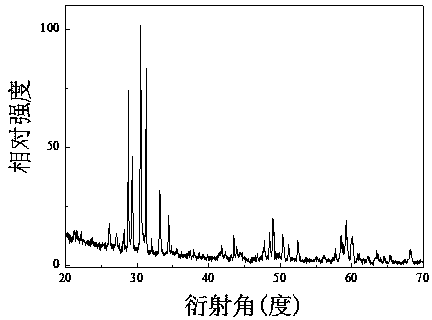

[0030] See attached figure 1 , which is a comparison between the X-ray powder diffraction pattern of the sample prepared according to the technical scheme of this embodiment and the standard card PDF#54-1216. The XRD test results show that the prepared material is a single-phase material.

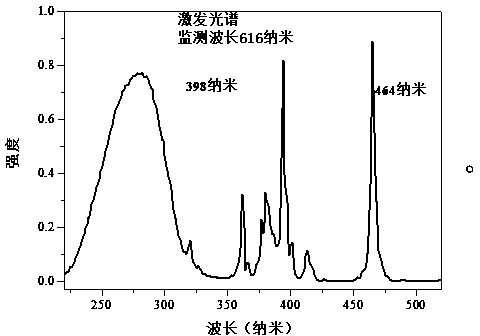

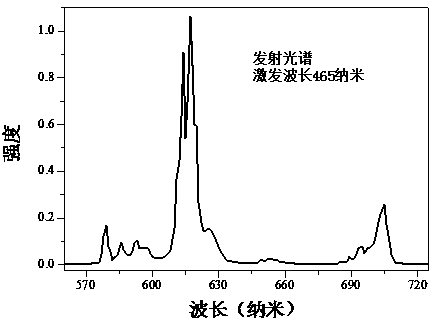

[0031] See attached figure 2 , is the ...

Embodiment 2

[0034] Press La 10.2 Eu 0.8 P 3 SiO 26 Weigh the molar ratio of each element in: europium oxide 0.352g, lanthanum oxide 4.1542g, ammonium dihydrogen phosphate 0.8627g, silicon dioxide 0.153g; grind and mix all the raw materials weighed well in an agate mortar; select In an air atmosphere, pre-fire the homogeneously mixed raw materials in a muffle furnace at 650°C for 7 hours, cool to room temperature; grind and mix evenly, sinter in a muffle furnace at 950°C for 5 hours, cool to room temperature and grind Mix evenly, sinter in a muffle furnace at 1400°C for 13 hours, and cool to room temperature to obtain La 10.2 Eu 0.8 P 3 SiO 26 red phosphor.

[0035] According to the X-ray diffraction spectrum of the material sample prepared by the technical scheme of this embodiment, the excitation and emission spectra are respectively the same as figure 1 , 2 and 3 are approximate.

Embodiment 3

[0037] Press Sm 10.2 Eu 0.8 P 3 SiO 26 The molar ratio of each element in the formula is weighed: europium oxide 0.352g, samarium oxide 4.577g, ammonium dihydrogen phosphate 0.8627g, silicon dioxide 0.153g; all the raw materials weighed are ground and mixed in an agate mortar; In an air atmosphere, pre-fire the homogeneously mixed raw materials in a muffle furnace at 650°C for 8 hours, cool to room temperature; grind and mix evenly, sinter in a muffle furnace at 900°C for 6 hours, cool to room temperature and grind Mix well, sinter in a muffle furnace at 1400°C for 13 hours, cool to room temperature to obtain Sm 10.2 Eu 0.8 P 3 SiO 26 red phosphor.

[0038] According to the X-ray diffraction spectrum of the material sample prepared by the technical scheme of this embodiment, the excitation and emission spectra are respectively the same as figure 1 , 2 and 3 are approximate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com