Synthesis technology for visible light titanium dioxide nanosheet with exposed {001} face and oxygen defects

A technology of titanium dioxide and synthesis process, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of high electron-hole recombination rate, low sunlight utilization rate, low quantum efficiency, etc., and achieve simple preparation process , Obvious single crystal diffraction, particle uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

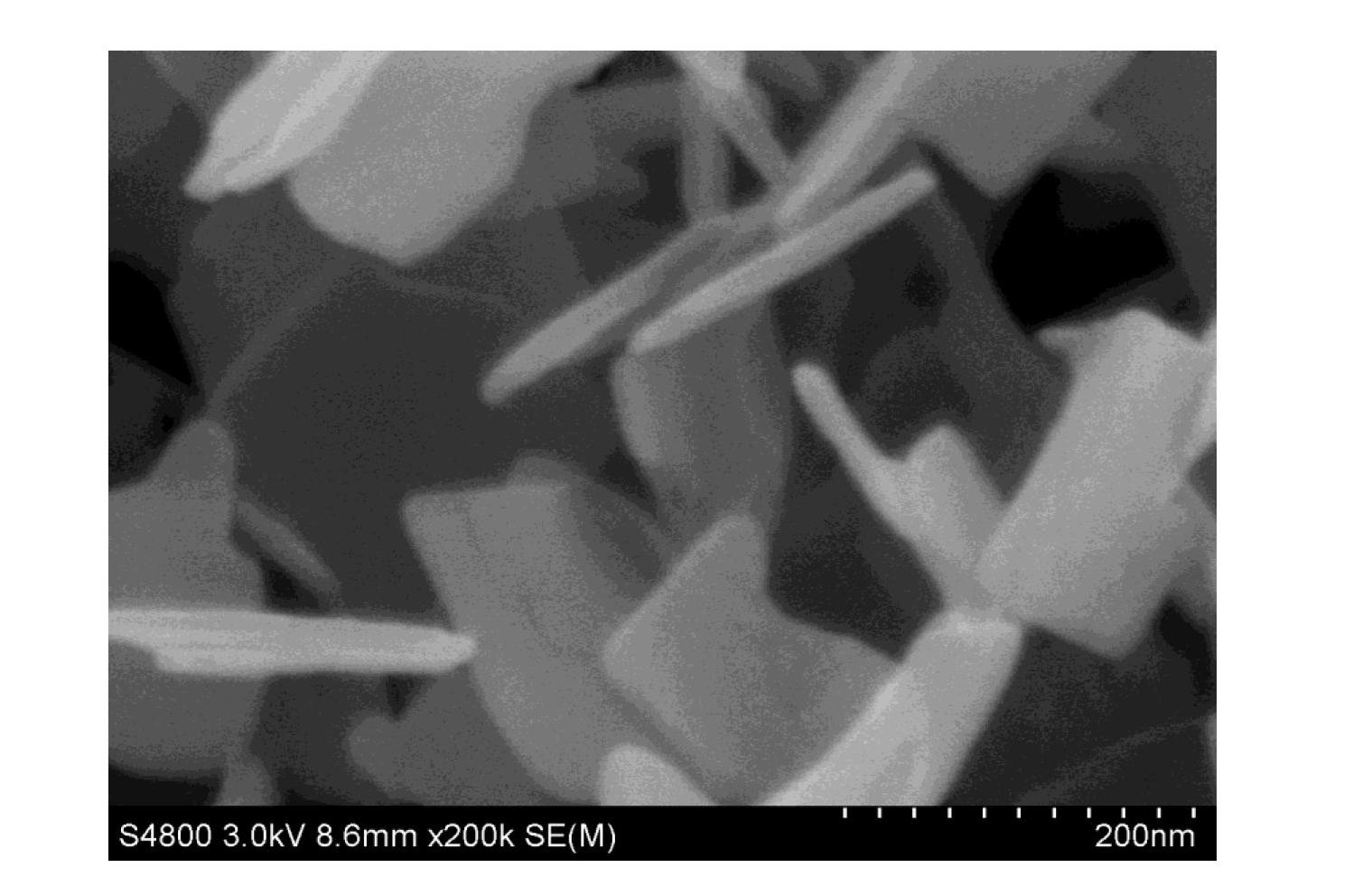

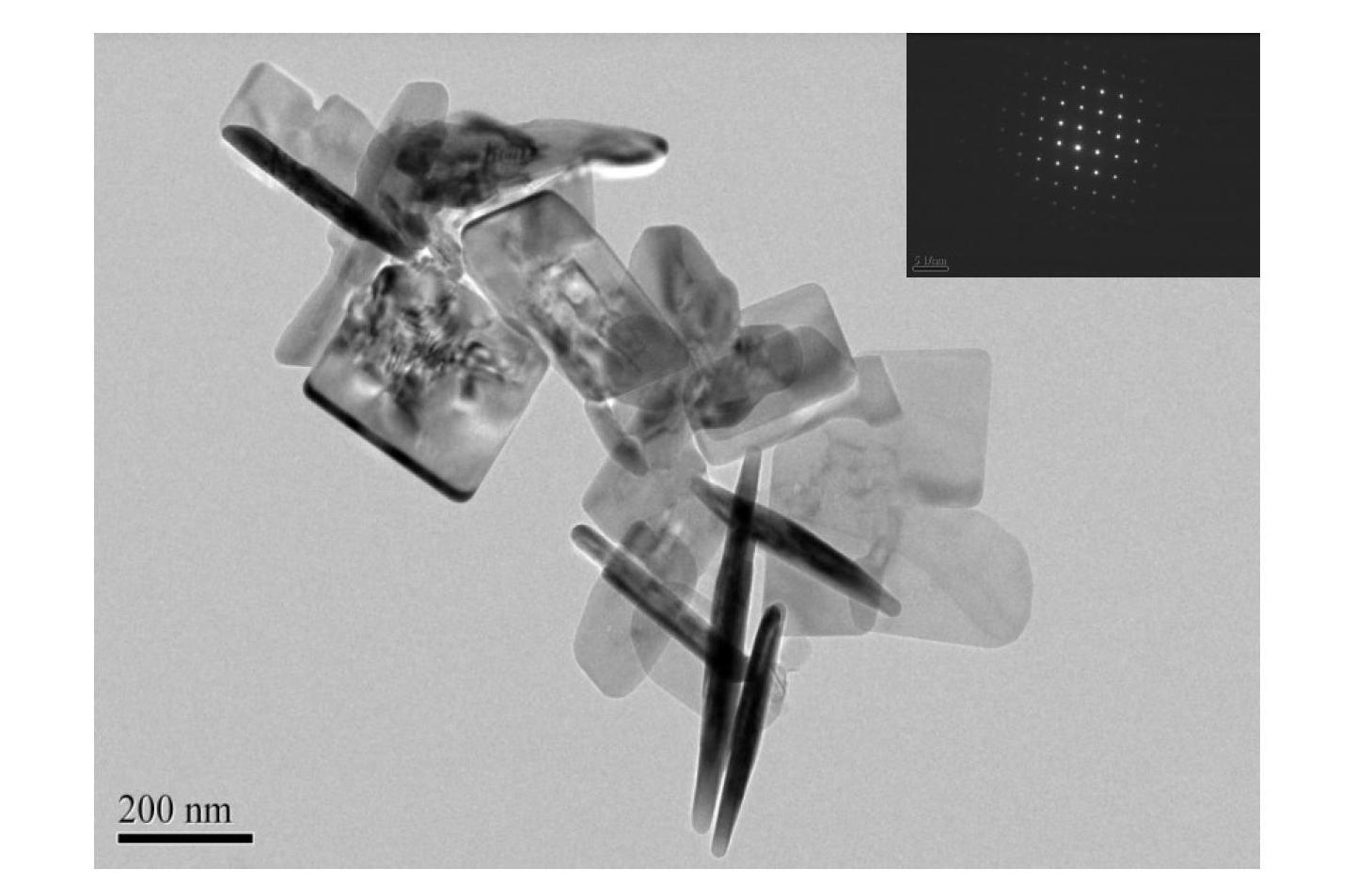

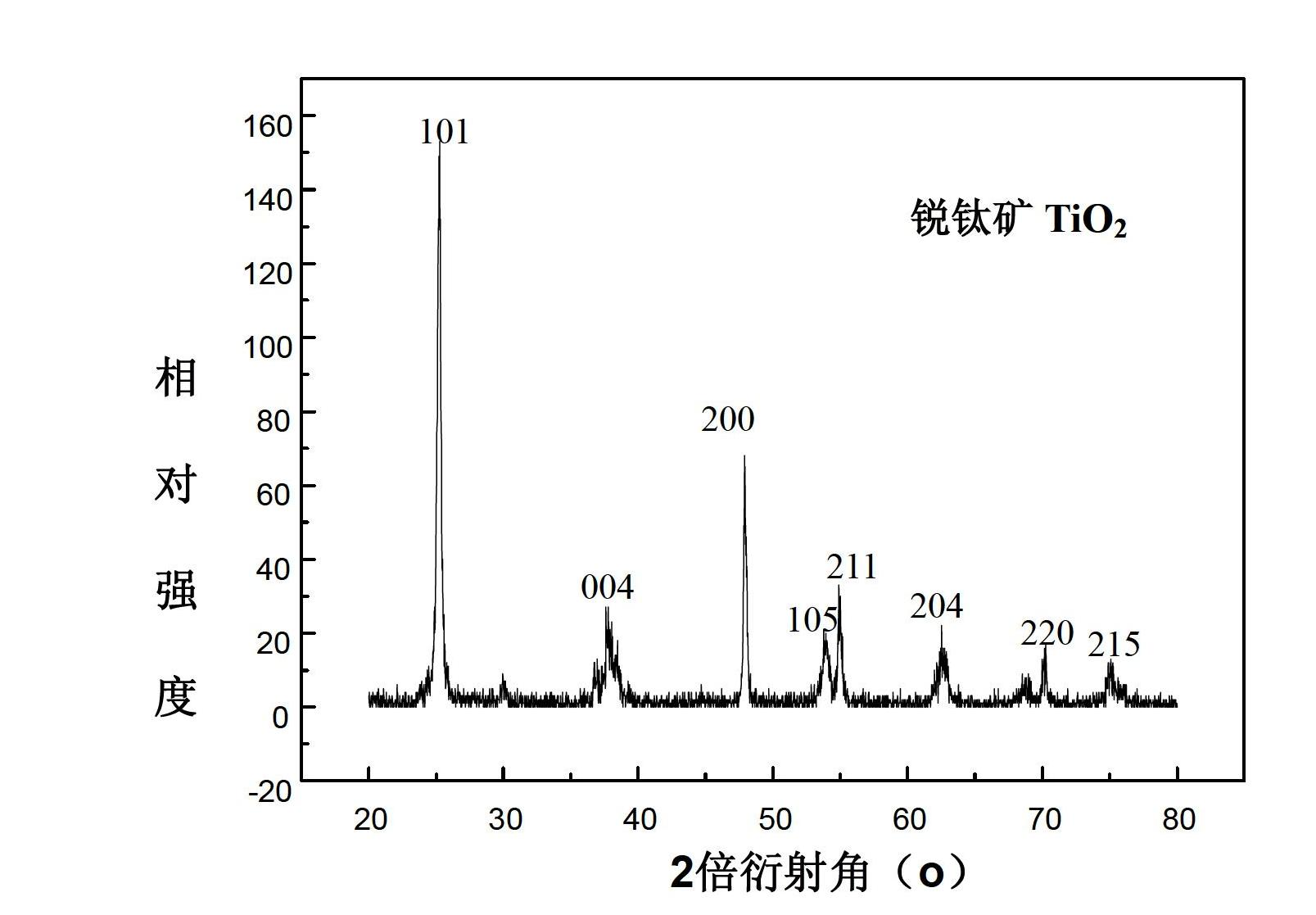

[0025] Dissolve butyl titanate and titanium tetrafluoride with a molar ratio of 1:2 in a mixed solution of 1.25mL 20% nitric acid aqueous solution and 25mL ethanol to obtain solution A. The molar volume ratio of Ti element to the solution is 3:26.25. The solution was aged at 40°C for 2 days to form a gel, and then placed in a supercritical reactor filled with 250mL of ethanol, aged at 260°C for 2h for extraction, and finally the samples were collected directly after the extraction cooled down. attached figure 1 The FESEM spectrum of the morphology of visible-light titania nanosheets with oxygen defects exposed on the {001} surface obtained in this case is given. It can be seen from the figure that the sample is a single crystal nanosheet. attached figure 2 The TEM image of visible titanium dioxide nanosheets with oxygen defects exposed on the {001} surface obtained in this case is given. The size is about 200nm and the thickness is about 10nm. The electron diffraction of the...

Embodiment 2

[0027] Repeat the operation steps of Example 1, the difference is that in the supercritical reactor, aging at 270 ° C for 2h extraction, the result is similar to Example 1, but the nanosheets become larger and thinner. The microstructure of the sample is consistent with that of Example 1, the crystallinity is consistent with that of Example 1, and the diffuse reflectance results show that the sample has a visible light response.

Embodiment 3

[0029] Repeat the operation steps of Example 1, the difference is that in the supercritical reactor, aging at 280 ° C for 2h extraction, the result is similar to Example 1, but the nanosheets become relatively larger and thinner. . The microstructure of the sample is consistent with that of Example 1, the crystallinity is consistent with that of Example 1, and the diffuse reflectance results show that the sample has a visible light response.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com