Segmented copolymer, preparation method thereof and hydrogel

A block copolymer and hydrogel technology, applied in the field of biomedical polymer materials, can solve the problem that injectable hydrogels do not have electrical activity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The invention discloses a preparation method of a block copolymer, comprising the following steps:

[0052] A) Under anaerobic conditions, N-isopropylacrylamide, methacrylic acid, polyethylene glycol monomethyl ether methacrylate and 2-methylene-1,3-dioxepane were induced Under the action of an agent, a polymerization reaction occurs in an organic solvent to obtain an intermediate;

[0053] B) The intermediate in the step A) is condensed with the compound having the structure of formula (VI) under the action of a coupling agent in an organic solvent to obtain a block copolymer; the block copolymer includes The A block with the structure of formula (I), the B block with the structure of formula (II), the C block with the structure of formula (III), the D block with the structure of formula (IV) and the block with the structure of formula (V) E block;

[0054]

[0055]

[0056] In formula (I), x is the degree of polymerization, 20≤x≤200, preferably 50≤x≤150;

[0...

Embodiment 1

[0080]Add 3.68g (0.02mol) of N-methyl-1,4-p-phenylenediamine into a mixture dissolved in 100mL of acetone, 100mL of water and 25mL of concentrated hydrochloric acid, and freeze to 0°C. Then weigh 4.56g (0.02mol) of ammonium persulfate and dissolve it in 50mL of 1mol / L HCl, slowly drop the ammonium persulfate solution into the mixed solution under ice bath, and control the dropping time to 0.5h. Ammonium was completely dropped into the mixed solution and then reacted for 3 hours. After the reaction was completed, the solid was obtained by filtration, and then the solid was washed with 0.6mol / L HCl and acetone successively, and then counter-doped with 0.5mol / L ammonia water, and finally the solid was washed with water three times to neutrality, and then vacuum-dried after freeze-drying to obtain The compound of formula (VI-a) has a yield of 80%.

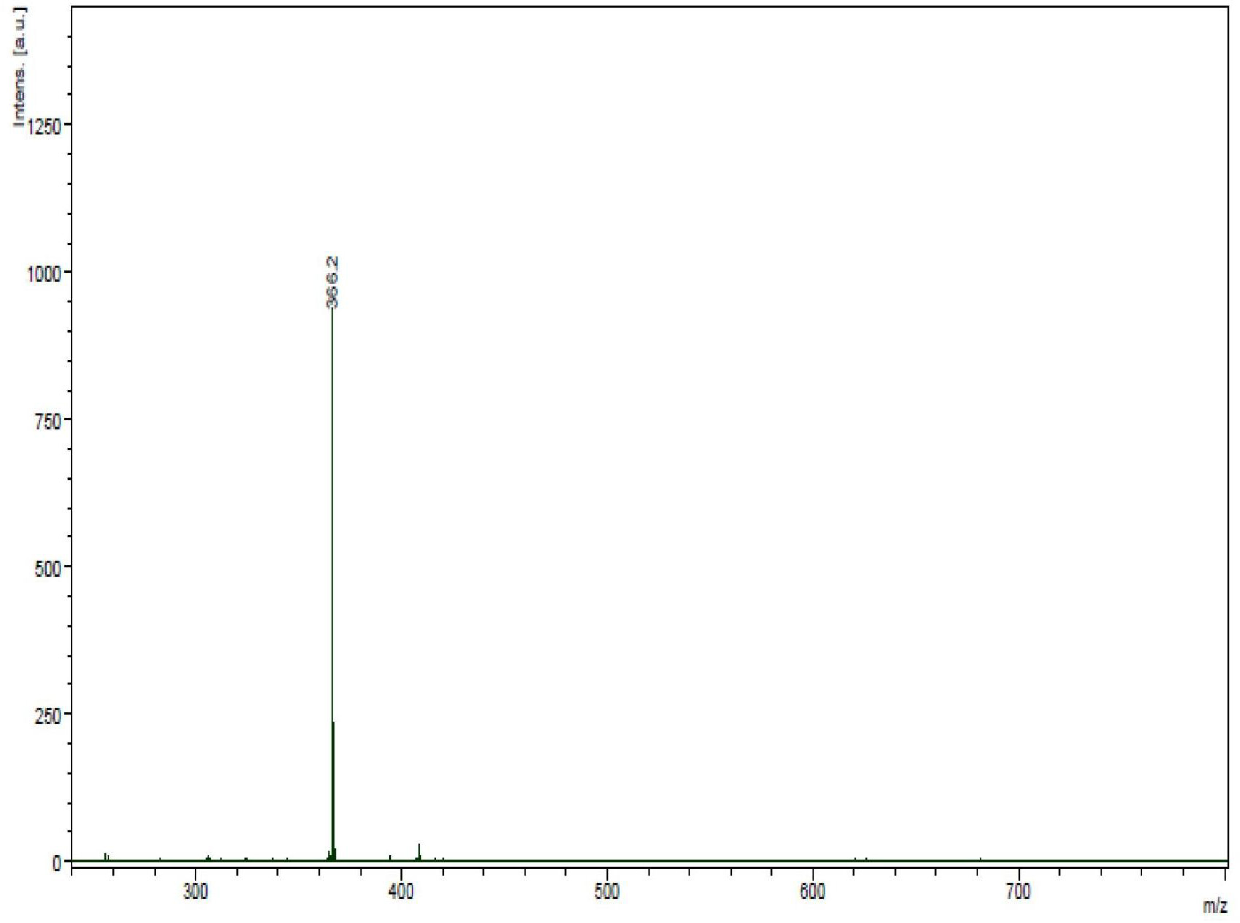

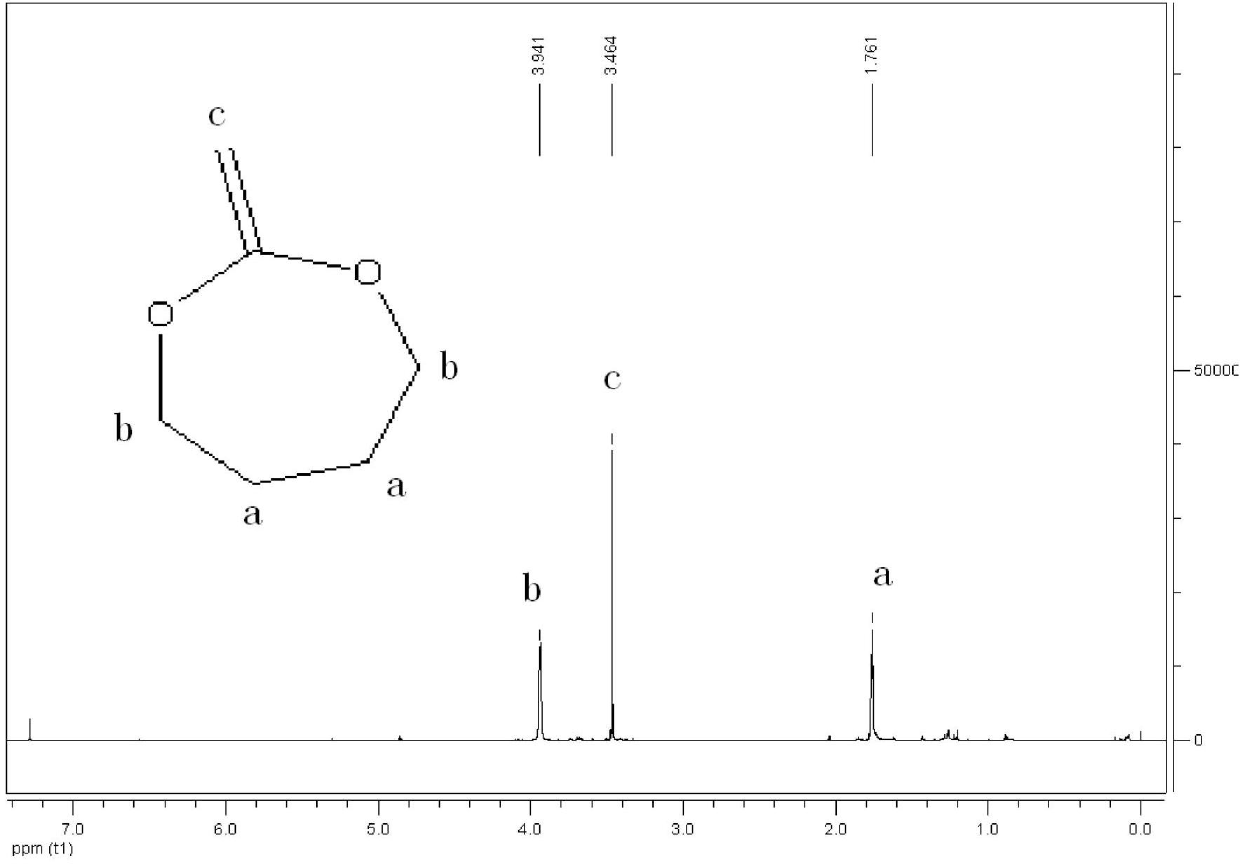

[0081] The obtained compound is detected, and the results can be found in figure 1 , figure 1 The matrix-assisted laser desorption...

Embodiment 2

[0083] Add 3.5g N-methyl-1,4-p-phenylenediamine and 2.6g N,N-diphenyl-1,4-p-phenylenediamine in N,N-dimethylformamide, 15mL water , 15mL of concentrated hydrochloric acid mixture, frozen to 0 ℃. Then weigh 2.28g (0.01mol) of ammonium persulfate and dissolve it in 50mL of 1mol / L HCl, slowly drop the ammonium persulfate solution into the mixture under ice bath, control the dropping time to 0.5h, and flow the acid Ammonium was completely dropped into the mixed solution and then reacted for 1 h. After the reaction, the product was poured into 700mL of water for precipitation, filtered, washed three times with 0.1mol / L HCl, then washed three times with water, then counter-doped with 0.1mol / L ammonia water, and finally washed with water three times until neutral, after lyophilization After vacuum drying, the compound with the structure of formula (VI-b) was obtained with a yield of 80%.

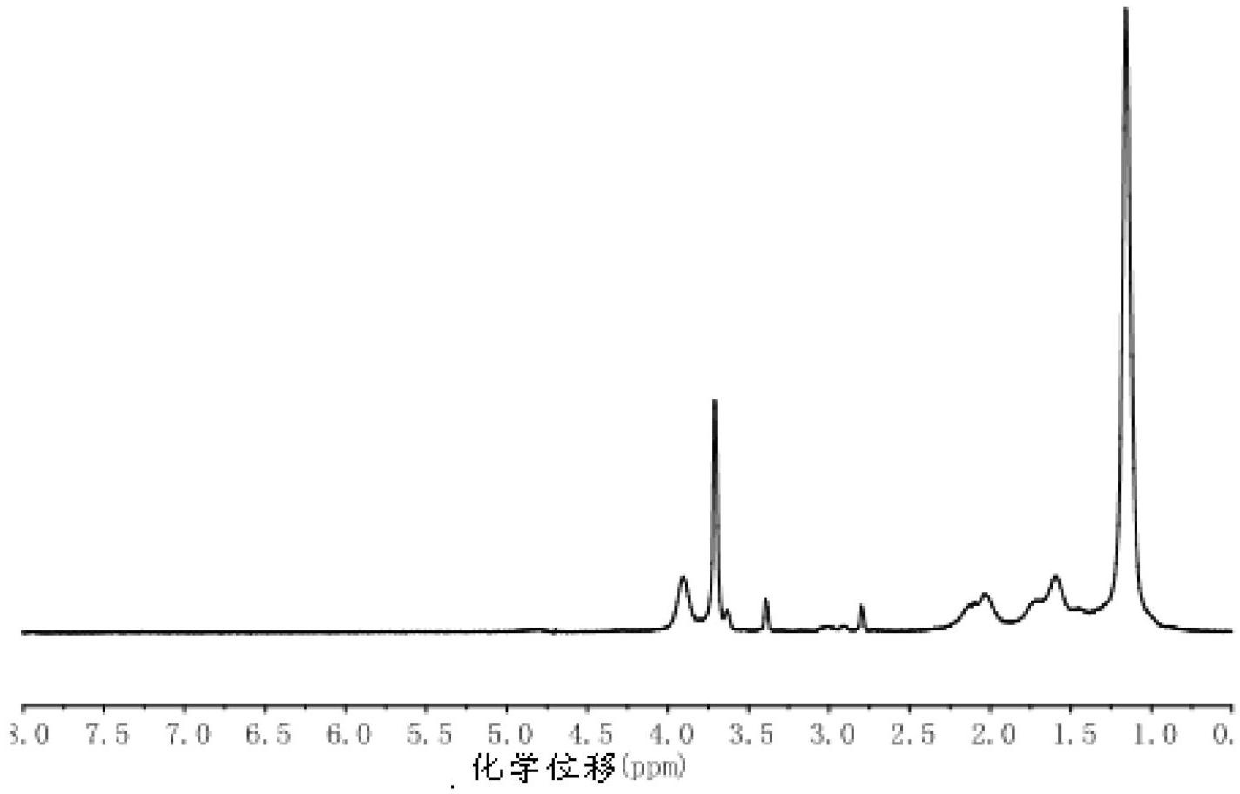

[0084] The obtained compound was detected by matrix-assisted laser desorption time-of-flight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com